Bioethanol. Is it possible to switch to a new fuel?

Content

Bioethanol production

Bioethanol, like biodiesel, is produced from plant materials. More often than others, two crops are taken for the manufacture of bioethanol: corn and sugar cane. For example, the production of bioethanol in the United States is mainly based on corn, in Brazil - on sugar cane. However, other plants with a high content of starch and vegetable sugars can also be used as raw materials: potatoes, sugar beet, sweet potato, etc.

In the world, the production of bioethanol is most developed in America. The production capacities of Brazil and the United States together account for more than half (more precisely, over 60%) of the world's production of this fuel.

At its core, bioethanol is ordinary ethyl alcohol (or ethanol), which is used in the manufacture of alcoholic beverages with the well-known chemical formula C2H5ooh However, bioethanol is not suitable for food consumption due to the presence of special additives, fuel additives. In addition to tert-butyl methyl ether (MTBE), which increases the detonation resistance of biofuels, reduces the corrosiveness of alcohols and is a carrier of additional oxygen involved in combustion, small amounts of other additives are added to bioethanol.

Several technologies for the production of bioethanol are known.

- Fermentation of organic products. Known since ancient times and the easiest method for obtaining ethyl alcohol. During yeast fermentation of sugar-containing mixtures, a solution with a mass content of ethanol of about 15% is obtained. With an increase in concentration, yeast bacteria die, which leads to a stop in the production of ethyl alcohol. Subsequently, alcohol is separated from the solution by distillation. Currently, this method is not used in the industrial production of bioethanol.

- Production using recombinant drugs. The raw material is crushed and fermented with glucoamylase and amylosubtilin. After that, distillation is carried out in accelerating columns with the separation of alcohol. A widely used method for the industrial production of bioethanol.

- hydrolysis production. In fact, this is the production of alcohol from pre-hydrolyzed cellulose-containing raw materials by industrial fermentation. It is used mainly in Russia and other post-Soviet countries.

Currently, the world production of bioethanol, according to various estimates, is somewhat short of 100 million tons per year.

Bioethanol. Price per liter

The cost of bioethanol production per 1 liter depends on several factors.

- The initial cost of raw materials grown for processing.

- The efficiency of the raw materials used (production technology and the ratio of the resulting bioethanol to the amount of raw materials involved).

- Logistics of production (the closer to the plantations with raw materials are processing enterprises, the cheaper the production, since transportation costs in the case of this type of fuel play a more significant role than in the production of petroleum gasoline).

- The cost of production itself (manufacturability of equipment, remuneration of workers, energy costs).

Therefore, in different countries, the cost of producing 1 liter of bioethanol varies. Here is the cost of this fuel per liter in some countries of the world:

- USA - $0,3;

- Brazil - $ 0,2;

- in general for European manufacturers - about $ 0,5;

For comparison, the average cost of producing gasoline is about $0,5 to $0,8 per liter, if you do not take into account crude oil exporting countries like Saudi Arabia or Venezuela, where a liter of gasoline costs less than a liter of water.

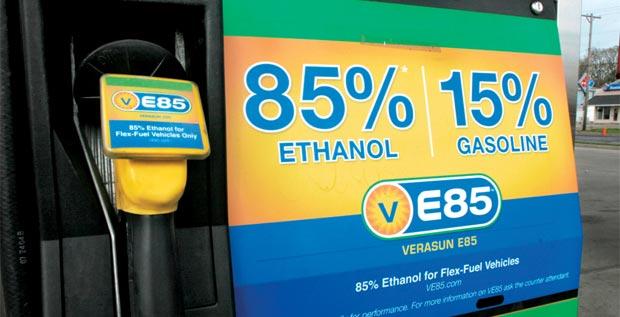

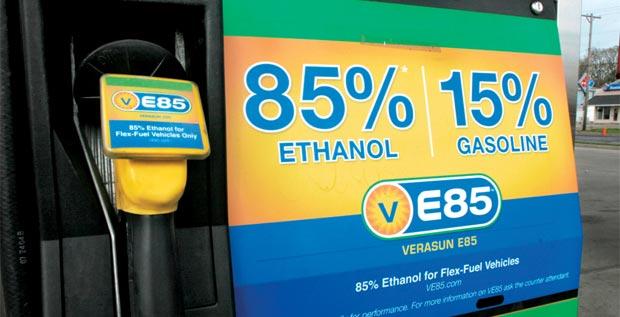

Bioethanol E85

Perhaps the lion's share among all types of fuel containing bioethanol is occupied by the E85 brand. This type of fuel is 85% bioethanol and 15% regular petroleum gasoline.

These fuels are only suitable for specially designed vehicles capable of running on biofuels. They are usually labeled as Flex-fuel cars.

Bioethanol E85 is widely distributed in Brazil, and is also found in the United States. In Europe and Asia, E5, E7 and E10 grades are more common with a bioethanol content of 5, 7 and 10 percent, respectively. The rest of the volume in these fuel mixtures is traditionally allocated to regular gasoline. Also recently, E40 fuel with a 40% bioethanol content is gaining popularity.

//www.youtube.com/watch?v=NbHaM5IReEo

Advantages and disadvantages of bioethanol

Let's look at the benefits of bioethanol first.

- Relative cheapness of production. This is provided that the country-manufacturer does not have its own, abundant oil reserves, and the crop industry is developed. For example, Brazil, which has few own oil reserves nationwide, but has developed agriculture and a favorable climate, it is much more profitable to make fuel based on bioethanol.

- Environmental friendliness of exhaust. Pure bioethanol emits only water and carbon dioxide when burned. No heavy hydrocarbons, soot particles, carbon monoxide, sulfur- and phosphorus-containing components are emitted into the atmosphere when the engine runs on bioethanol. According to a comprehensive assessment (taking into account all the parameters assessed according to the EURO standard), the purity of exhaust gases turned out to be 8 times higher for engines running on bioethanol.

- Renewability. If oil reserves are finite (a proven fact today: theories about the regenerative nature of oil as emissions from the bowels of the Earth are rejected by the world scientific community), then the production of bioethanol depends only on the yield of plantations.

- Lower fuel consumption. On average, when driving on bioethanol, with a properly configured fuel system, up to 15% of fuel is saved in a volume ratio. Conventionally, instead of 10 liters of gasoline, a car will use only 100 liters of bioethanol per 8,5 kilometers.

The disadvantages of this type of fuel, especially in relation to the existing fleet of vehicles, are currently significant.

- Excessive consumption of bioethanol in a car in which the ECU does not have settings for working on biofuel. And in general, there is often a low efficiency of a motor that is not designed for vegetable fuel. The fact is that the energy density and the required volumetric ratio of air and fuel in bioethanol differs from gasoline. This leads to unstable operation of the engine.

- Destruction of rubber and plastic seals. The properties of rubber and plastic that allow these materials to be virtually neutral with respect to petroleum energy carriers cannot provide chemical resistance to ethanol. And the seals, which can withstand interaction with gasoline for decades, are destroyed in a matter of months by constant contact with alcohol.

- Quick failure of an engine that is not designed to drive on bioethanol. As a consequence of the two previous points.

Based on the foregoing, we can conclude that bioethanol will be an excellent alternative to conventional gasoline if the car is designed for this type of fuel.

Watch this video on YouTube