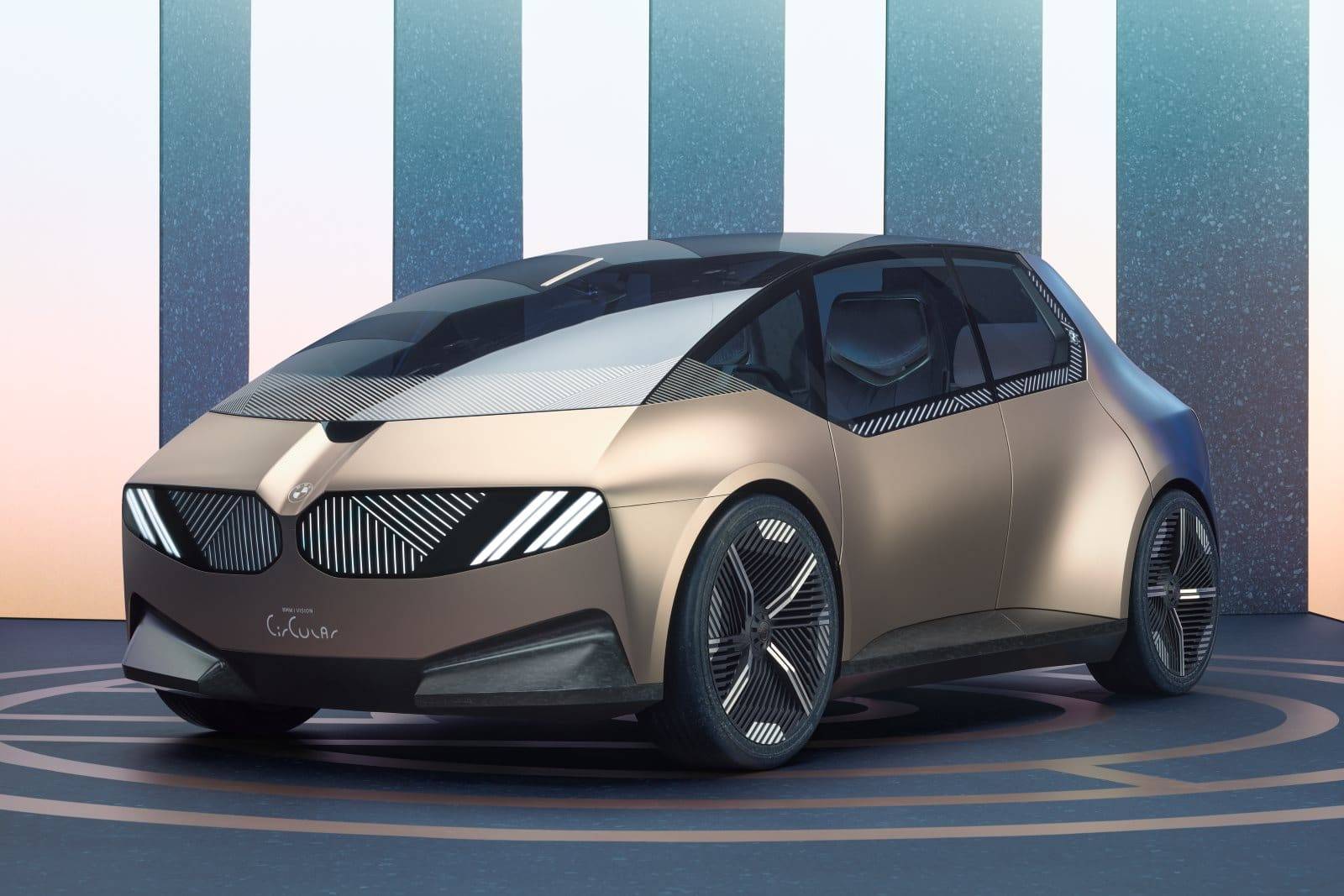

BMW will produce wheels from recycled aluminum using 100% sustainable technology.

BMW knows that contributing to the environment does not only mean the production of electric vehicles. The car company will now aim to develop recycled aluminum wheels with a goal of cutting supply chain emissions by up to 20% by 2030.

When you think of the auto industry's drive to cut carbon emissions, most people immediately think of electric vehicles. While automakers left and right are pushing for an electric future, making cars environmentally friendly is more than just replacing internal combustion engines with electric motors, especially when it comes to manufacturing them. For this reason, wheels for all BMW Group vehicles will soon be produced using "100% green energy".

BMW cares about the environment

On Friday, BMW announced its plans to completely cast wheels from sustainable sources and clean energy by 2024. BMW produces almost 10 million wheels each year, 95% of which are cast aluminum. The planned changes will ultimately result in annual savings of 500,000 tons of CO2 through reduced emissions and material use in wheel production.

How BMW will implement its green wheels plan

The plan consists of two main parts, which will lead to the achievement of environmental sustainability of production. The first part has to do with an agreement that BMW has made with its manufacturing partners to use 100% clean energy from factories that help supply parts.

The wheel casting process and the electrolysis operation consume a lot of energy during production. More importantly, according to BMW, wheel production accounts for 5% of all emissions in the supply chain. Helping offset 5% of anything, especially a large-scale operation, is quite a feat.

The second part of the plan to reduce CO2 emissions in manufacturing is to increase the use of recycled aluminium. Mini Cooper and its parent company BMW plan to use 70% recycled aluminum in the production of new wheels starting in 2023. This "secondary aluminum" can be smelted in furnaces and turned into aluminum ingots (bars), a recycling center that will be smelted again in the smelting process to create new wheels.

BMW has a purpose

From 2021, BMW will only source new aluminum for the rest of its components from the United Arab Emirates at a facility that uses solar energy exclusively. By increasing the amount of recycled materials and using renewable energy in the supply chain and manufacturing processes, BMW hopes to reduce supply chain emissions by 20% by 2030.

BMW is not alone in this process. Ford, which has been making heavy trucks out of aluminum for years, says it recycles enough aluminum every month to make 30,000 cases of its F- model. And that was a few years ago, so it's probably even more now.

As automakers strive to build cleaner cars, it's also important to focus on cleaner manufacturing methods in general.

**********

: