Faster, Quieter, Cleaner - New Aircraft Engine

It turns out that in order to change a lot in aviation, you do not need to look for new propellers, futuristic designs or space materials. It is enough to use a relatively simple mechanical transmission ...

This is one of the most important innovations of recent years. Geared turbofan motors (GTF) allow the compressor and fan to rotate at different speeds. The fan drive gear rotates with the fan shaft but separates the fan motor from the low pressure compressor and turbine. The fan rotates at a slower speed, while the compressor and low pressure turbine operate at a higher speed. Each engine module can operate at optimum efficiency. After 20 years of R&D and R&D spending of around $1000 billion, the Pratt & Whitney PurePower PW2016G turbofan family was operational a few years ago and has been massively introduced into commercial aircraft since XNUMX.

Modern turbofan engines generate thrust in two ways. First, the compressors and combustion chamber are located at its core. At the front is a fan which, driven by the core, directs air through the bypass chambers around the motor core. The bypass ratio is the ratio of the amount of air passing through the core to the amount of air passing through it. In general, a higher bypass ratio means quieter, more efficient and more powerful engines. Conventional turbofan engines have a bypass ratio of 9 to 1. Pratt PurePower GTF engines have a bypass ratio of 12 to 1.

To increase the bypass ratio, motor manufacturers must increase the length of the fan blades. However, when elongated, the rotational speeds obtained at the end of the blade will be so high that unwanted vibrations will occur. You need fan blades to slow down, and that's what the gearbox is for. Such an engine can be as high as 16 percent, according to Pratt & Whitney. great fuel economy and 50 percent. less exhaust emissions and is 75 percent. quiet. Recently, SWISS and Air Baltic announced that their GTF C-series jet engines consume even less fuel than the manufacturer promises.

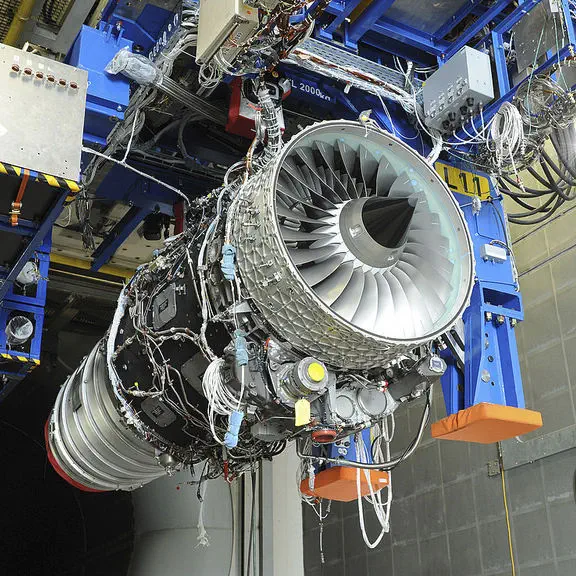

PW1100G-JM engine on a production line

TIME magazine named the PW1000G engine one of the 50 most important inventions of 2011 and one of the six most environmentally friendly inventions, as Pratt & Whitney PurePower is designed to be cleaner, quieter, more powerful and use less fuel than existing jet engines. In 2016, Richard Anderson, then president of Delta Air Lines, called the engine "the first true innovation" since Boeing's Dreamliner revolutionized composite construction.

Savings and reduction of emissions

The commercial aviation sector emits more than 700 million tons of carbon dioxide annually. Although it is only about 2 percent. global carbon dioxide emissions, there is evidence that greenhouse gases in jet fuel have a greater impact on the atmosphere as they are released at higher altitudes.

Major engine manufacturers are looking to save fuel and reduce emissions. Pratt competitor CFM International recently introduced its own advanced engine called the LEAP, which company officials say delivers similar results to a geared turbofan at the expense of other solutions. CFM claims that in a traditional turbofan architecture, the same benefits can be achieved without the added weight and drag of the powertrain. LEAP uses lightweight composite materials and carbon fiber fan blades to achieve energy efficiency improvements that the company says are comparable to those achieved with the Pratt & Whitney engine.

To date, orders for Airbus engines for the A320neo are roughly evenly split between CFM and Pratt & Whitney. Unfortunately for the latter company, PurePower motors are causing problems for users. The first appeared this year, when uneven cooling of GTF engines was recorded in Qatar Airways Airbus A320neo. Uneven cooling can lead to deformation and friction of parts, and at the same time increase the time between flights. As a result, the airline concluded that the engines did not meet operational requirements. Shortly thereafter, the Indian aviation authorities suspended the flights of 11 Airbus A320neo aircraft powered by PurePower GTF engines. According to the Economic Times, the decision came after Airbus GTF-powered aircraft suffered three engine failures over the course of two weeks. Pratt & Whitney downplays these difficulties, saying they are easy to overcome.

Airbus electronic fan

Another giant in the field of aircraft engines, Rolls-Royce, is developing its own Power Gearbox, which by 2025 will reduce fuel consumption in large turbofans by 25%. compared to older models of the well-known Trent engine range. This, of course, means a new Pratt & Whitney design competition.

The British are also thinking about other kinds of innovation. During the recent Singapore Airshow, Rolls-Royce launched the IntelligentEngine Initiative, which aims to develop intelligent aircraft engines that are safer and more efficient through the ability to communicate with each other and through a support network. By providing continuous two-way communication with the engine and other parts of the service ecosystem, the engine will be able to solve problems before they occur and learn how to improve performance. They would also learn from the history of their work and other engines, and by and large they would even have to repair themselves on the go.

Drive needs better batteries

The European Commission's aviation vision for 2050 calls for a reduction in CO emissions.2 by 75 percent, nitrogen oxides by 90 percent. and noise by 65 percent. They cannot be achieved with existing technologies. Electric and hybrid-electric propulsion systems are currently seen as one of the most promising technologies to meet these challenges.

There are two-seat electric light aircraft on the market. Four-seater hybrid-electric vehicles are on the horizon. NASA predicts that in the early 20s, this type of short haul, nine-seat airliner will bring aviation services back to smaller communities. Both in Europe and in the US, scientists believe that by 2030 it is possible to build a hybrid-electric aircraft with a capacity of up to 100 seats. However, significant progress will be required in the field of energy storage.

Currently, the energy density of batteries is simply not enough. However, all this could change. Tesla boss Elon Musk said that once the batteries are capable of producing 400 watt-hours per kilogram, and the ratio of cell power to total weight is 0,7-0,8, the electric transcontinental airliner will become a "difficult alternative." Considering that lithium-ion batteries were able to achieve an energy density of 113 Wh/kg in 1994, 202 Wh/kg in 2004, and are now able to reach about 300 Wh/kg, it can be assumed that within the next decade they will reach the level 400 Wh/kg.

Kitty Hawk electric two-seater air taxi project

Airbus, Rolls-Royce and Siemens recently partnered to develop the E-Fan X flying demonstrator, which will be a significant step forward in commercial aircraft hybrid-electric propulsion. E-Fan X hybrid electric technology demonstration expected to be -Fan X will fly in 2020 after an extensive ground test campaign. In the first phase, the BAe 146 will replace one of the four engines with a XNUMX MW electric motor. Subsequently, it is planned to replace the second turbine with an electric motor after demonstrating the maturity of the system.

Airbus will be responsible for the overall integration as well as the hybrid electric propulsion and battery control architecture and its integration with flight control systems. Rolls-Royce will be responsible for the gas turbine engine, XNUMX-megawatt generator and power electronics. Together with Airbus, Rolls-Royce will also work on adapting the fans to the existing Siemens nacelle and electric motor. Siemens will supply XNUMX MW electric motors and an electronic power controller, as well as an inverter, converter and power distribution system.

Many research centers around the world are working on electric aircraft, including NASA, which is building the X-57 Maxwell. The Kitty Hawk electric two-seater air taxi project and many other structures of large centers, companies or small start-ups are also being developed.

Given that the average lifespan of passenger and cargo aircraft is around 21 and 33 years, respectively, even if all new aircraft produced tomorrow are all-electric, it would take two to three decades to phase out fossil-fuel-powered aircraft.

So it won't work quickly. Meanwhile, biofuels can lighten the environment in the aviation sector. They help reduce carbon dioxide emissions by 36-85 percent. Despite the fact that biofuel mixtures for jet engines were certified in 2009, the aviation industry is in no hurry to implement changes. There are few technological hurdles and challenges associated with bringing biofuel production to industrial levels, but the main deterrent is price — it takes another ten years to achieve parity with fossil fuels.

Step into the Future

At the same time, the labs are working on somewhat more futuristic aircraft engine concepts. So far, for example, a plasma engine does not sound very realistic, but it cannot be ruled out that scientific works will develop into something interesting and useful. Plasma thrusters use electricity to create electromagnetic fields. They compress and excite a gas, such as air or argon, into a plasma—a hot, dense, ionized state. Their research now leads to the idea of launching satellites in outer space (ion thrusters). However, Berkant Goeksel of the Technical University of Berlin and his team want to put plasma thrusters on planes.

The objective of the study is to develop an air-jet plasma engine that could be used for both takeoff and high-altitude flights. Plasma jets are typically designed to operate in a vacuum or low pressure atmosphere where a gas supply is required. However, Göksel's team tested a device capable of operating in air at a pressure of one atmosphere. “Our plasma nozzles can reach speeds of up to 20 kilometers per second,” Göckel says in the Journal of Physics conference series.

SABER engine in the hypersonic vehicle of the future

To begin with, the team tested miniature thrusters 80 millimeters long. For a small aircraft, this will be up to a thousand of what the team considers possible. The biggest limitation, of course, is the lack of lightweight batteries. The scientists are also considering hybrid aircraft, in which the plasma engine will be combined with internal combustion engines or rockets.

When we talk about innovative jet engine concepts, let's not forget the SABER (Synergistic Air-Breathing Rocket Engine) developed by Reaction Engines Limited. It is assumed that this will be an engine operating both in the atmosphere and in vacuum, running on liquid hydrogen. At the initial stage of the flight, the oxidizer will be air from the atmosphere (as in conventional jet engines), and from a height of 26 km (where the ship reaches a speed of 5 million years) - liquid oxygen. After switching to rocket mode, it will reach speeds of up to Mach 25.

HorizonX, Boeing's investment arm involved in the project, has yet to decide how SABER could use it, except that it expects to "use revolutionary technology to help Boeing in its quest for supersonic flight."

RAMJET and scramjet (supersonic jet engine with a combustion chamber) have long been on the lips of fans of high-speed aviation. Currently, they are developed mainly for military purposes. However, as the history of aviation teaches, what will be tested in the army will go to civil aviation. All it takes is a little patience.

Rolls Royce Intelligent Engine Video:

Rolls-Royce | Innovation in IntelligentEngine