That he will always shoot

Electrical connections, especially ignition wires in older vehicles, are most susceptible to damage in the late fall. The enemy of their proper functioning is, first of all, the ubiquitous moisture absorbed from the atmosphere. The latter increases the risk of corrosion of electrical connections, thereby contributing to the breakdown of the current, which, in turn, leads to difficulties in starting the engine. However, ignition cables are not everything. In order for the ignition system to work properly, you should also check the operation of its other elements, especially spark plugs.

Ignition and glow

The need for a detailed check of the ignition system applies to all vehicles, ranging from gasoline and diesel, ending with gas and gas vehicles. In the latter case, this control is especially important, since gas engines require higher voltage than traditional units. When checking the ignition system, pay special attention to the spark plugs. Burnt or worn surfaces require much more voltage to generate a spark, which in turn often leads to a burn or rupture of the ignition wire sheath. Glow plugs used in diesel engines must also be carefully checked. With the help of a meter, their technical condition is checked by assessing, among other things, whether they are heating up correctly. Burnt out glow plugs will cause trouble starting your car in cold weather. Damaged spark plugs - both spark plugs and glow plugs - must be replaced immediately. However, if in gasoline engines this applies to all spark plugs, then in diesel engines this is usually not necessary (in many cases it is enough to replace burned-out ones).

Dangerous punctures

On examination, it often turns out that one of the ignition wires is damaged, for example, as a result of a puncture in its insulation. This is especially dangerous, because, in addition to difficulty starting the engine, a cable with damaged insulation can lead to an electric shock of several thousand volts! Experts emphasize that in this case it is not limited to replacing the faulty one. Always replace all cables so that the current flows evenly through them. Spark plugs should also be replaced along with the cables: if worn, they will shorten the life of the cables. Be careful when disconnecting the ignition cables and do not pull on the cables as you can easily damage the terminal or spark plug. Ignition wires should also be replaced prophylactically. Workshops recommend replacing them with new ones after a run of about 50 thousand. km. As a general rule, cables with low resistance should be used, i.e. cables with the lowest possible voltage drop. In addition, they must also match the specific power supply of the drive unit.

New cables - so what?

The most recommended by professionals are cables with a ferromagnetic core. Like the commonly used copper wires, they have low resistance with low EMI. Due to the above properties of the ferromagnetic core, these cables are ideal for vehicles equipped with gas installations, both LPG and CNG. Ignition cables with copper cables are also a good choice, which is why they are successfully used in lower class vehicles as well as in BMW, Audi and Mercedes vehicles. The advantage of cables with a copper core is a very low resistance (strong sparking), the disadvantage is a high level of electromagnetic interference. Copper wires are cheaper than ferromagnetic ones. An interesting fact is that they are often found in ... rally cars. The least popular type is the third type of carbon core ignition cables. What is it coming from? First of all, due to the fact that the carbon core has a high initial resistance, it wears out quickly, especially with intensive use of the car.

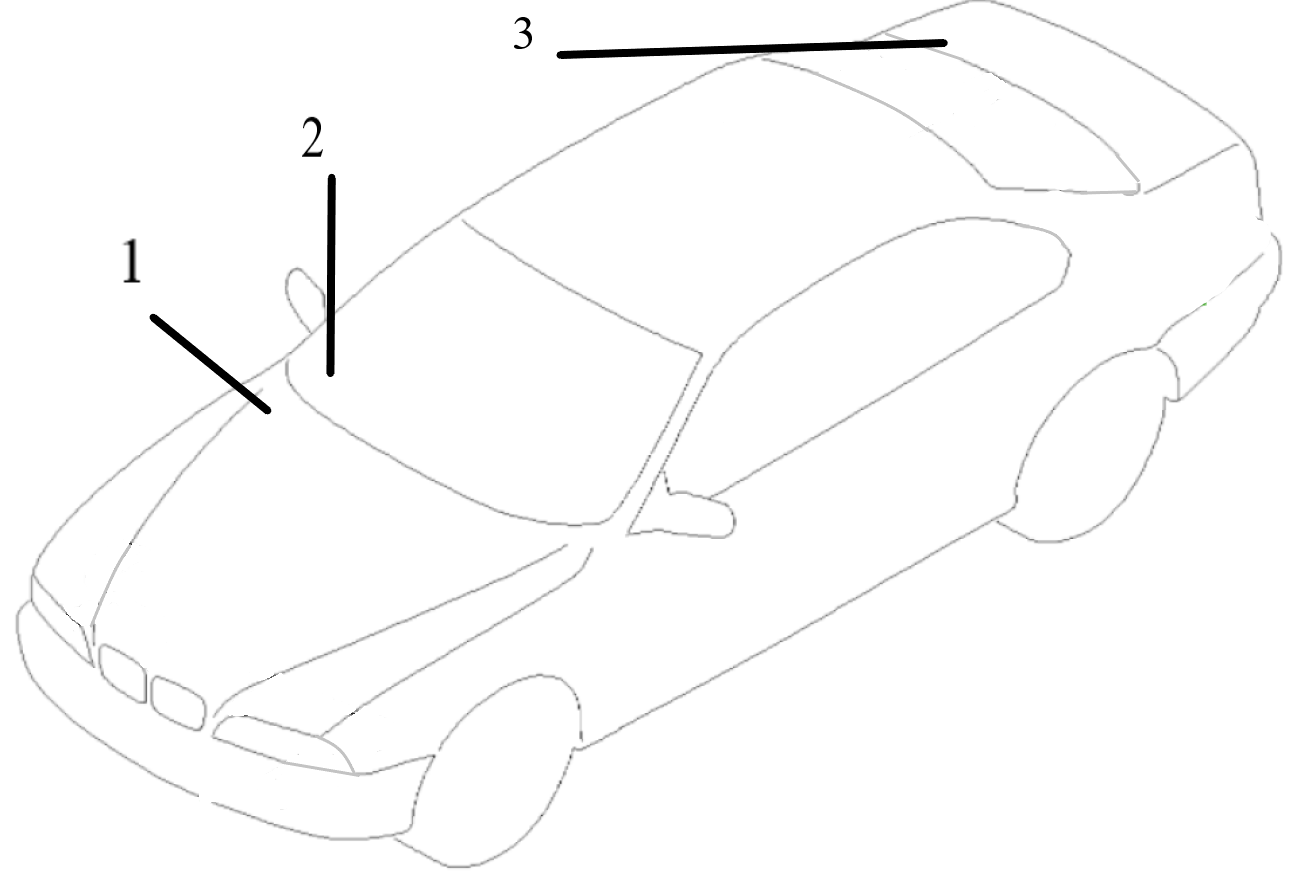

No (cable) problems

Owners of younger cars with gasoline engines do not have to deal with the ignition cable problems described above. Cause? In the ignition systems of their cars, those cables just... disappeared. In the latest solutions, instead of them, integrated modules of individual ignition coils for each cylinder are installed in the form of a cartridge that is worn directly on the spark plugs (see photo). The electrical circuit without ignition cables is much shorter than traditional solutions. This solution significantly reduces power losses, and the spark itself is supplied only to the cylinder that performs the working cycle. Initially, integrated individual ignition coil modules were used in six-cylinder and larger engines. Now they are also installed in four- and five-cylinder units.