What are insulated plugs?

Content

Sometimes your digging tools may need electrical insulation. Perhaps you need to dig narrow trenches for cabling or irrigation work, or you just need to dig. The problem is that you have to dig around underground cables or electrified train tracks.

Sometimes your digging tools may need electrical insulation. Perhaps you need to dig narrow trenches for cabling or irrigation work, or you just need to dig. The problem is that you have to dig around underground cables or electrified train tracks.What is electrical isolation?

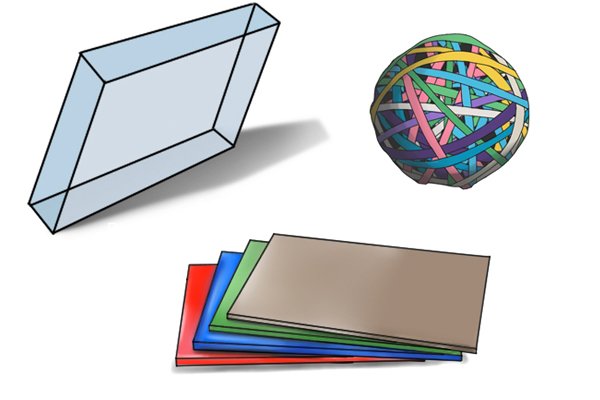

An electrical insulator is a material that resists the flow of electricity. In other words, it does not allow electricity to easily pass through it. Materials such as glass, plastic, and rubber are some examples of insulators.

An electrical insulator is a material that resists the flow of electricity. In other words, it does not allow electricity to easily pass through it. Materials such as glass, plastic, and rubber are some examples of insulators.

So, some kind of electric current still passes?

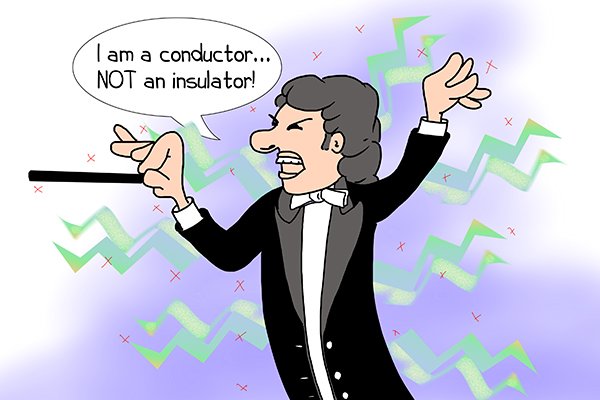

There is no perfect insulator, but don't worry. Some materials, such as rubber, plastic, and fiberglass, have high resistivity (a measure of the strength of a material to withstand electrical current) and are good insulators for moderate electrical currents. However, most metals are conductors of electricity. In other words, electricity will easily pass through a plug with a steel head and shaft.

Insulated forks

There are various steps you should take to avoid potential damage, and using an insulated digging tool is one of them. In this section, we will look at insulated digging forks.

There are various steps you should take to avoid potential damage, and using an insulated digging tool is one of them. In this section, we will look at insulated digging forks. However, before we move on, make sure all insulated hand tools meet British standards for working on or near live cables.

However, before we move on, make sure all insulated hand tools meet British standards for working on or near live cables.Insulated digging hand tools are typically tested for voltages up to 10,000 to 1,000 volts. An isolation guarantee of up to XNUMX volts is then issued, which fully complies with the working specifications of the live cable. In addition, all insulated hand tools are assigned a unique tracking number.

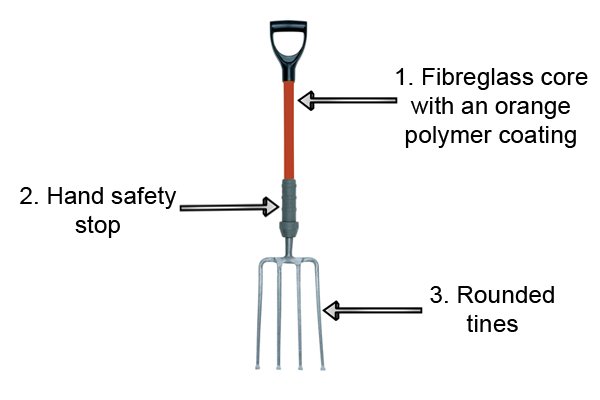

Insulated plugs are very similar in design and the models are generally the same. There are three main safety factors to consider when choosing a particular plug:

Insulated plugs are very similar in design and the models are generally the same. There are three main safety factors to consider when choosing a particular plug:1. Strong fiberglass core and insulating layer for the shaft.

2. Built-in manual stop.

3. Rounded teeth

Safety factor 1 - strong fiberglass core and a layer of insulating material for the shaft.

Fiberglass is strong yet lightweight and has excellent insulating properties.

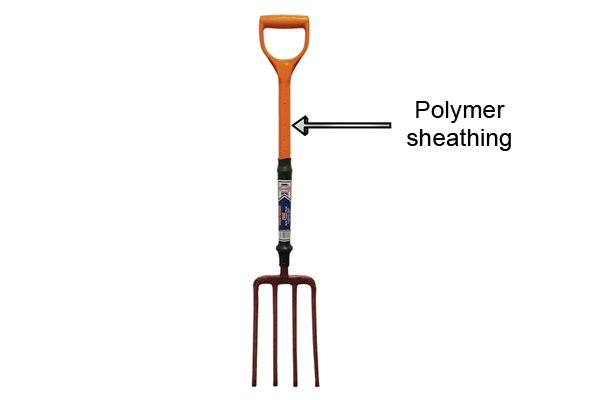

A layer or two of polymer - an insulator and an abrasion resistant material - coat the fiberglass, providing additional protection. Some manufacturers apply two coats.

Manufacturers love to dazzle us with science buzzwords! Polymer is just another word used for plastic. The fiberglass core coating is typically polypropylene, a strong and flexible thermoplastic material used for an extremely wide range of applications, including electrical insulation.

Manufacturers love to dazzle us with science buzzwords! Polymer is just another word used for plastic. The fiberglass core coating is typically polypropylene, a strong and flexible thermoplastic material used for an extremely wide range of applications, including electrical insulation. For your information, a polymer is a large group of synthetic and natural materials. Plastic, polystyrene, and nylon are one form of synthetic polymer, while rubber and amber are natural polymers.

For your information, a polymer is a large group of synthetic and natural materials. Plastic, polystyrene, and nylon are one form of synthetic polymer, while rubber and amber are natural polymers.Polymers are made up of many identical molecules (known as monomers) linked together by chemical bonds to form very long chains (as well as other rather complex structures!)

Check that there are any wear indicators on the shaft housing that signal the need to replace the tool. For example, when the outer protective layer is destroyed, the white inner layer becomes visible. Either change the tool or use it as a non-isolated tool.

Check that there are any wear indicators on the shaft housing that signal the need to replace the tool. For example, when the outer protective layer is destroyed, the white inner layer becomes visible. Either change the tool or use it as a non-isolated tool.Safety factor 2 - integrated manual stop

A specially shaped insulating collar or palm rest prevents the user's hand from accidentally slipping onto the steel blade. The collar is usually rubber. Remember, steel conducts electricity. If one of the prongs pierces the insulation of one of the cables, you must not put your hand near the steel head of the plug!

Safety factor 3 - rounded teeth

For added protection, the cutting edges of the teeth are rounded or slightly blunt to reduce the risk of damage to pipes and cables.

Any difference between different insulated plug designs is negligible. If there is a discrepancy, then it will be in the size of the head. This type of fork is commonly used by contractors and for heavy earthworks. Therefore, the teeth will be slightly larger than average, typically around 300 x 200 mm (12 x 8 inches).