What is an engine crankcase (purpose, location and design)

Content

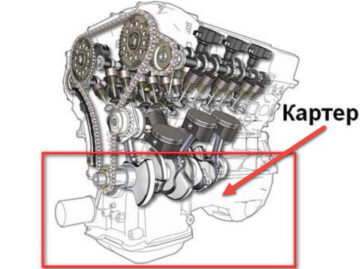

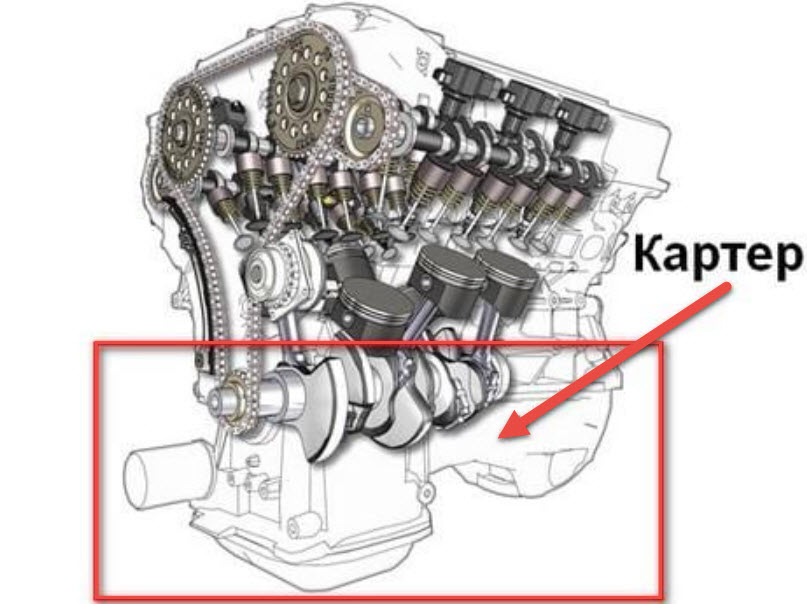

The approximate concept of a crankcase is known to everyone who has at least a little studied the design of an internal combustion engine (ICE). But many believe that only one part is hidden under it, which is actually called the oil pan. A more general concept is rather theoretical, it is not a specific part or assembly, but means the entire space of the motor located below the cylinders.

Why does an engine need a crankcase

In the vast majority of motors, the crankcase is used to locate an oil bath in it and a number of components that ensure the operation of the lubrication system.

But since it occupies a rather significant volume, it is in it that many other mechanisms are located:

- crankshaft with its bearings and mounting beds cast in the block;

- details of the ventilation system of gases formed during operation;

- lip seals at the exit points of the front and rear ends of the crankshaft;

- thrust half rings, fixing the shaft from longitudinal displacement;

- oil pump with coarse filter;

- balance shafts that balance the crank mechanism of theoretically unbalanced engines;

- nozzles for additional lubrication and piston cooling;

- oil dipstick and oil level sensor.

Outdated lower motors also used a camshaft installed in the crankcase, and the valves were driven through pushers in the form of rods going to the head of the block.

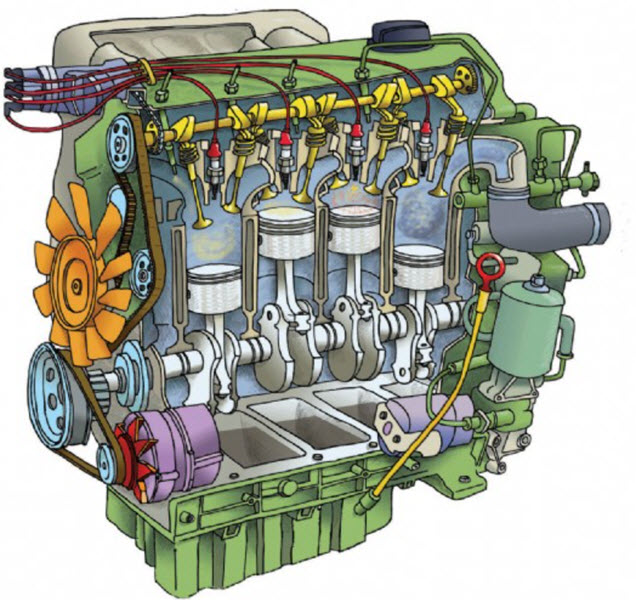

Design

Usually the crankcase consists of the lower part of the casting of the cylinder block and connected to it through the sump gasket.

But there are also more complex designs, where an intermediate plate is screwed to the block from below, covering the beds of the crankshaft with main bearings. So with a decrease in the mass of the block, additional rigidity is provided, which is important for the long-term operation of the piston group.

This is especially important for engines made entirely of light alloys, even imperceptible block deformations lead to uneven cylinder wear and scuffing.

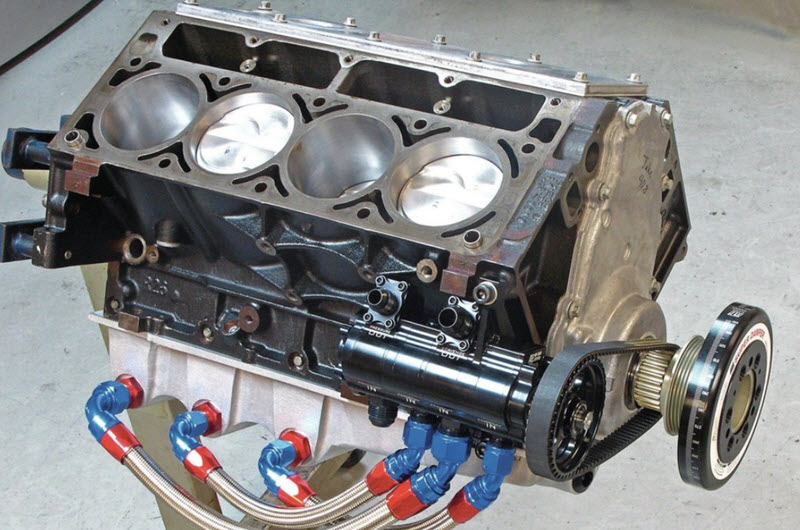

The oil pump is mounted at or below the front end of the crankshaft, in which case it is driven by a separate chain from the crankshaft sprocket. Balancers can be placed in shaft beds or combined into a monoblock with a lower oil pump, forming a functionally complete module.

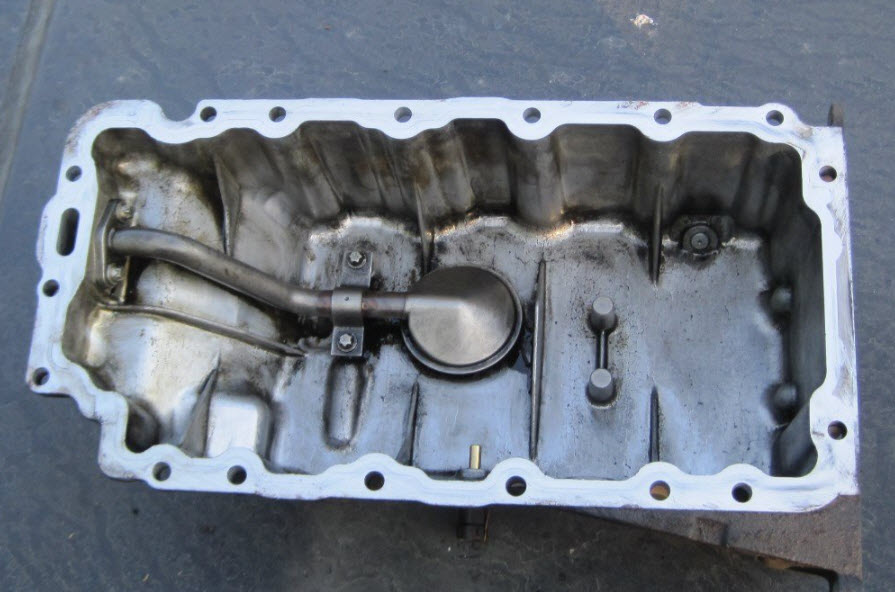

The rigidity of the structure is provided by cast fins and additional baffles, in which holes can be made to reduce pumping losses from the bottom of the pistons.

Heat is removed through oil circulation, for which sometimes the pan is also cast from a light alloy with developed cooling fins. But more often the pallet is stamped from thin steel, it is cheaper and more reliable in case of possible impacts from hitting obstacles.

Types of crankcases

Depending on the type of engine, additional functions may be assigned to the crankcase.

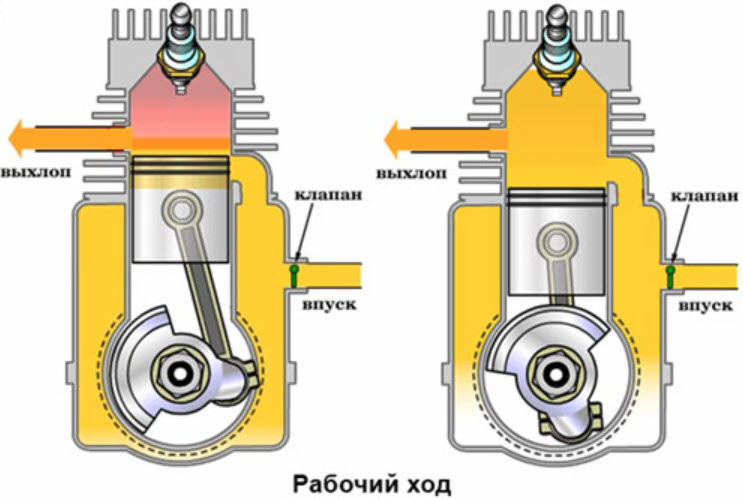

Two-stroke engine crankcase

In two-stroke engines, the crankcase is used to pre-compress the mixture. It is sucked into the under-piston space during the compression stroke in the cylinder.

During the downward movement of the piston, the pressure under it rises, and as soon as the bypass channel opens in the lower zone of the cylinder, the fuel mixed with air rushes to the combustion chamber. Hence the requirements for crankcase tightness, the presence of an inlet valve and high-quality crankshaft toe seals.

There is no oil bath, and lubrication is carried out by adding a certain amount of special two-stroke oil to the working mixture, which then burns with gasoline.

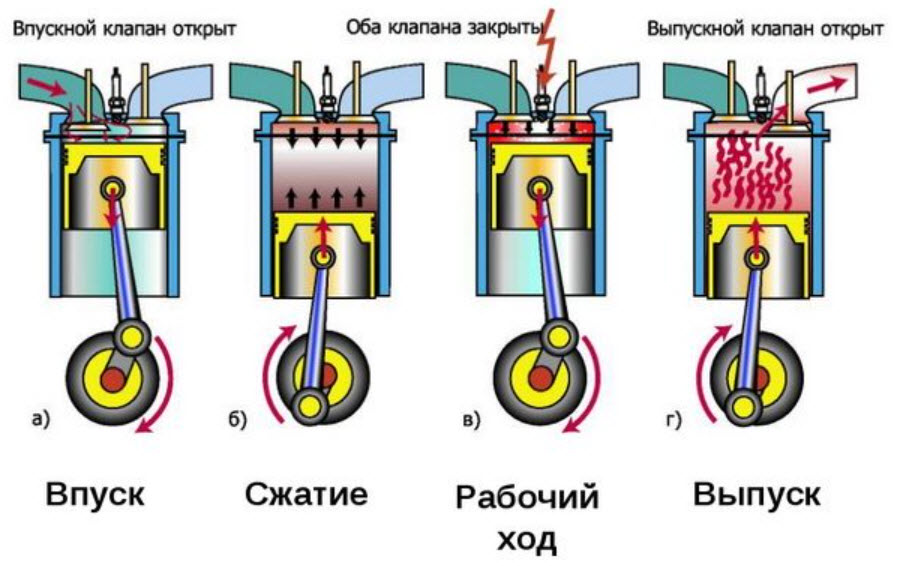

Four-stroke engine crankcase

With a four-stroke cycle, fuel can enter the crankcase only when a malfunction occurs. Under normal conditions, it serves to store the oil bath, where it flows after passing through the channels and friction pairs.

At the bottom of the sump there is an oil intake of the pump with a coarse mesh filter. A certain distance is observed between the crankshaft counterweights and the oil mirror in order to prevent foaming upon contact.

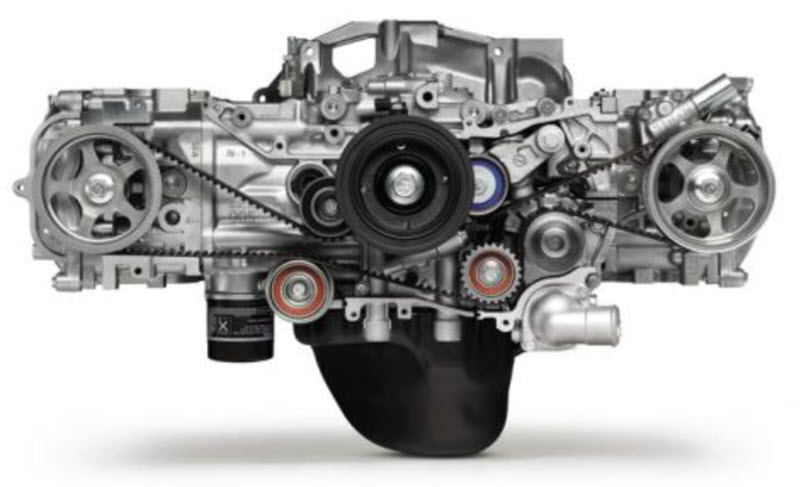

Boxer crankcase

In boxer engines, the crankcase is the main power element that stiffens the entire block. At the same time, it is compact, which provides one of the advantages of an automobile "boxer" - a low overall height, which reduces the overall center of mass of the car.

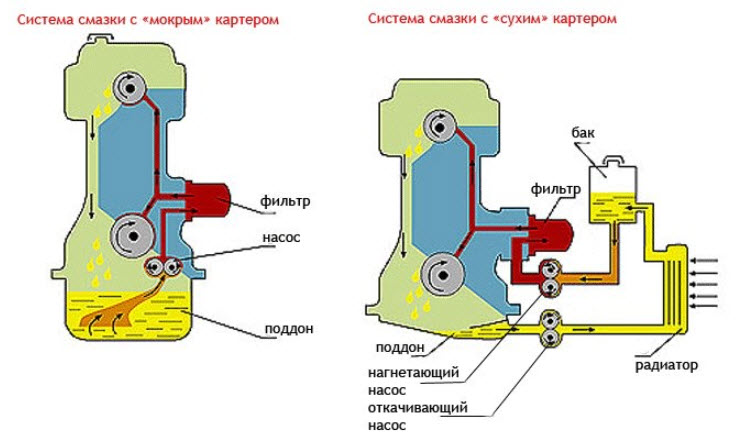

What is dry sump

It is possible to contain oil in the form of a bath filled to a certain level only under static or close to that conditions. Sports cars cannot provide anything like this, they experience constant strong accelerations in all directions, which is why the oil gets everywhere, but not to the oil pump receiver at the bottom of the sump.

Therefore, the lubrication system there is carried out with the so-called dry sump, when the oil does not linger below, but is immediately picked up by several powerful pumps, separated from the air and pumped to consumers.

The system becomes much more complicated, but there is no other way out. As in aviation, where the concept of top and bottom may not exist at all, the engine must also work in inverted flight.

Typical breakdowns

The main problem with the crankcase is that it hits an obstacle, after which a dent forms on the pallet at best. At worst, it will crack or move, the engine will lose oil, and without it, it will only have a few seconds to live.

A red indicator will light up in front of the driver on the instrument panel, after which you must immediately turn off the engine, without waiting for it to turn into a monolith.

Sometimes it happens that the crankcase is intact after the impact, but the light still signals a drop in pressure. This means that the elastic deformation of the sump caused the oil receiver tube, which is often made of aluminum alloy, to break.

The pump will entrain air and the lubrication system will fail. The result is the same - you can’t move on your own without repair.

Engine crankcase protection

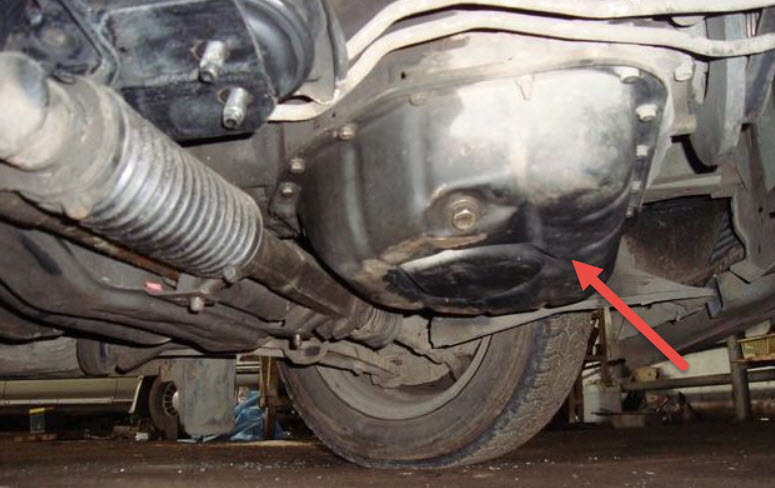

Whatever the ground clearance of the car, the obstacle can still be insurmountable. To avoid evacuation and repair in each such case, the crankcase is sought to be protected.

On cars and crossovers, unlike SUVs, protection is made maximum from splashes from under the wheels. Plastic shields will not help when hitting a stone. Therefore, metal rigid protection is installed as additional equipment.

You can also break through it, but having stiffeners and being attached to a power subframe, such a design will work like a ski, raising the entire front of the car. The probability of survival for the motor is greatly increased.

The protection sheet is made from stamped steel sheet, 2-3 mm thick, or about twice as thick as aluminum. The latter option is easier, but noticeably more expensive.

Those willing to pay for high technology can use Kevlar. When servicing the engine, the protective sheet can be easily removed, and the slots and holes made in it provide the necessary heat exchange, it is very undesirable to overheat the oil.