What is a car cylinder monitoring system?

Content

Shutdown system for cylinder control

Cylinder control system. In other words, this is a cylinder shutdown system. It is designed to change the displacement of the engine from the release of the cylinder. Using the system provides a reduction in fuel consumption by up to 20% and a reduction in harmful exhaust emissions. A prerequisite for the development of a cylinder control system is a typical mode of operation of the vehicle. At which the maximum power is used up to 30% for the entire period of operation. Thus, most of the time the engine runs at partial load. Under these conditions, the throttle is practically closed, and the engine must suck in the required amount of air for operation. This leads to so-called pumping losses and a further decrease in efficiency.

Cylinder Control

The cylinder management system allows you to turn off some cylinders with a small load on the engine. In this case, the throttle opens to provide the necessary power. In most cases, the brake system of the cylinders is used for multi-cylinder powerful engines, 6, 8, 12 cylinders. Whose operation is especially ineffective at low loads. To disable a particular slave cylinder, two conditions must be met. Turn off the air inlet and outlet, close the inlet and outlet valves, and turn off the fuel to the cylinder. Fuel supply control in modern engines is carried out using electronically controlled electromagnetic injectors. Maintaining closed intake and exhaust valves in a particular cylinder is a rather difficult technical task. What different automakers decide in their own way.

Cylinder management technology

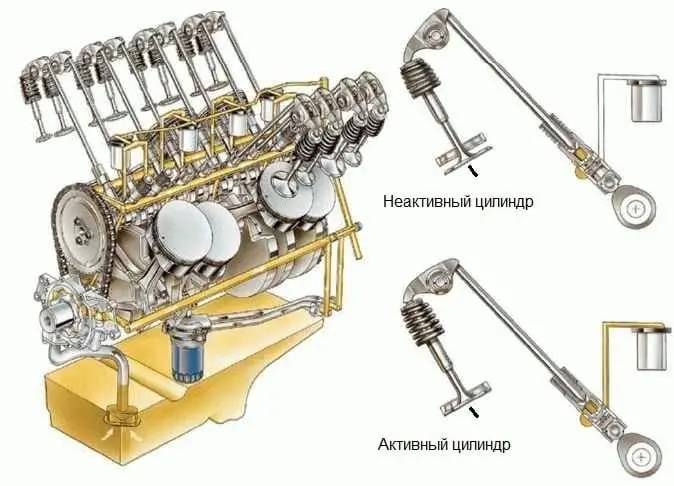

Among the various technical solutions, there are three approaches. The use of a special construction pusher, Multi-Displacement System, Displacement on Demand, the ability to turn off the rocker arm, the use of branched chambers of various shapes, technology of active cylinders. Forced shutdown of the cylinders, in addition to the undeniable advantages, has several disadvantages, including additional engine loads, vibration and unwanted noise. To prevent additional engine loads in the engine’s combustion chamber, the exhaust gas remains from the previous duty cycle. Gases are compressed when the piston moves up, and push the piston when it moves down, thereby providing a balancing effect.

Cylinder control system

To reduce vibration, special supports of the hydraulic motor and a two-mass flywheel are used. Noise reduction is performed in the exhaust system, in which the lengths of the pipes are selected and the front and rear silencers with resonators of different sizes are used. The cylinder control system was first used in 1981 for Cadillac vehicles. The system had electromagnetic coils mounted on molds. The actuation of the coil provided the rocker arm still, and at the same time, the valves were closed by the action of the springs. The system turned off the opposite pair of cylinders. The operation of the coil is controlled by an electronic device. Information on the number of cylinders in operation is displayed on the dashboard. The system was not widespread, as there were problems with the fuel supply for all cylinders, including those that were excluded.

Active cylinder management system

The ACC active cylinder system has been used on Mercedes-Benz vehicles since 1999. Closing the valves of the cylinders provides a special design, consisting of two levers connected by a lock. In the working position, the lock connects the two levers together. When deactivated, the latch releases the connection and each of the arms can move independently. However, the valves are closed by spring force. The movement of the lock is carried out by oil pressure, which is regulated by a special solenoid valve. Fuel is not supplied to the shut-off cylinders. In order to preserve the characteristic sound of a multi-cylinder engine with the cylinders deactivated, an electronically controlled valve is installed in the exhaust system, which, if necessary, changes the dimensions of the cross-section of the exhaust passage.

Cylinder control system

multi-position system. The Multi-Displacement System, MDS has been installed on Chrysler, Dodge, Jeep since 2004. The system activates, deactivates the cylinders at speeds above 30 kilometers per hour, and the engine crankshaft speeds up to 3000 rpm. The MDS system uses a specially designed piston that separates the camshaft from the valve when needed. At a certain time, oil is pressed into the piston under pressure and presses the locking pin, thereby deactivating the piston. The oil pressure is controlled by a solenoid valve. Another cylinder control system, displacement on demand, literally DoD - motion on demand similar to the previous system. The DoD system has been installed on General Motors vehicles since 2004.

Variable cylinder control system

Variable cylinder control system. A special place among the cylinder deactivation systems is occupied by the Honda VCM cylinder control system, which has been used since 2005. During steady driving at low speeds, VCM disconnects one cylinder block from the V-engine, 3 out of 6 cylinders. During the transition from maximum engine power to partial load, the system operates 4 cylinders out of six. The VCM system is structurally based on VTEC with variable valve timing. The system is based on rockers that interact with cameras of various shapes. If necessary, the swing is switched on or off using a locking mechanism. Other systems to support the VCM system have also been developed. The Active Motor Mounts system regulates the vibration level of the engine.

Cylinder control system for active noise reduction

The Active Sound Control system allows you to get rid of unwanted noise in the car. Active cylinder technology, ACT system, used in Volkswagen Group vehicles since 2012. The target for installing the system is a 1,4 liter TSI engine. The ACT system provides deactivation of two of the four cylinders in the 1400-4000 rpm range. Structurally, the ACT system is based on the Valvelift System, which was once used for Audi engines. The system uses humps of various shapes located on the sliding sleeve on the camshaft. Cameras and connectors form a camera block. In total, the engine has four blocks - two on the intake camshaft and two on the exhaust shaft.