What is a brake booster? How does a brake booster work?

Content

If you want to know what a brake booster is and how it affects the performance of the brake system, you should read our article about this inconspicuous element that is in every car equipped with power steering. We recommend that you read the following text to learn how to care for the brake booster and how to use it to its full potential.

Brake booster - what is it?

The brake booster is an extremely important element in a car that most drivers know about, but they do not know what exactly this part of the car is responsible for and how important it is in the context of driving safety.

The brake system depends on the fluid in the reservoir and hoses. The braking process itself can be simplified by pressing the brake pedal, which increases fluid pressure, puts pressure on the calipers and discs. As a result, the car stopped. Along the way, however, the brake booster performs an extremely important function. Without it, braking would be much more difficult, and at the same time it would increase the risk on the road.

The brake booster itself is maintenance-free and rarely fails. In addition, it is one of the cheapest spare parts. At the same time, it is ingenious in its simplicity and efficiency. It was invented in 1927 by engineer Albert Devandre. Bosch then bought the patent from him and distributed it as a brake booster.

The job of the servo is to increase the pressure on the master cylinder piston. This makes it possible to use the full potential of the braking system. As a result, you don't have to press hard on the brake pedal, as the system responds with proper braking, which is directly proportional to the driver's intentions.

What does a brake booster look like?

The brake booster can be compared to a disc, flattened can or drum. Located near the partition of the engine compartment on the side of the steering wheel. You will find it right behind the brake fluid reservoir as the servo itself is connected to it. It increases the force acting on the master cylinder piston when the driver presses the brake pedal.

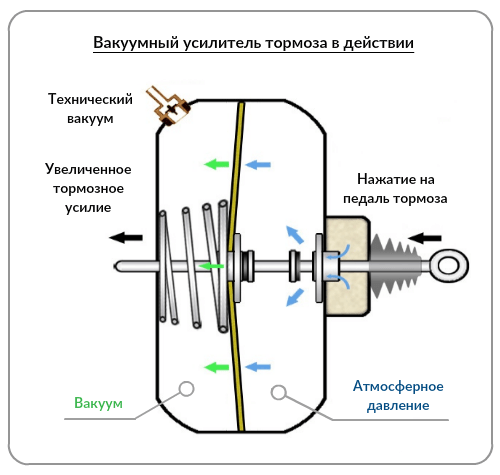

The brake booster has two chambers inside, which are separated by a sealed diaphragm. One of them is connected to the inlet pipe of the intake manifold, which increases the braking power. They are also connected by an air duct, so that the vacuum in them and the intake system remains at the same level.

What is the brake booster responsible for?

Simply put, the brake booster makes braking safer, more efficient and more economical. His work begins as soon as the brake pedal is pressed. It applies pressure to the master cylinder, which in turn opens the valve, allowing the vacuum from the manifold to act on the diaphragm. Thanks to him, the force acting on the diaphragm is directly proportional to the driver's pressure on the brake pedal. As a result, it can adjust the braking force. In this way, it is possible to prevent the driver from exerting a minimum pressure on the brake pedal and operating the mechanism with maximum effort.

The servo is maintenance-free and does not belong to the emergency parts of the car. Defects are most often manifested by brake fluid leaks or a hard brake pedal.

Brake assistance is extremely important in the context of safe driving. At the same time, it is felt by drivers only when it is not present.. For example, when towing a car with the engine off, you can quickly get a feel for what it would be like to drive a vehicle without a functioning brake booster. The brake pedal is much harder to press and becomes stiff after a short time. The pedal travel will be significantly reduced, which will make it difficult to brake. This is due to the lack of sufficiently high pressure in the brake system, which is created due to the operation of the brake booster.

Brake servo - work

The brake booster has two chambers (not to be confused with the engine chamber), which are separated by a rubber membrane. The larger chamber is under negative pressure, while the smaller one has a channel connecting it to the atmosphere, so that it is at atmospheric pressure.. Between them there is a channel, which is open most of the time. As a result, negative pressure is generated throughout the device. However, at the moment of braking, after pressing the brake pedal, the valve closes the channel connecting the two chambers, and a smaller chamber opens. Thus, the pressure rises sharply, due to which the diaphragm begins to move towards the larger chamber. The brake pump helps with this, on which the piston acts with increased force.

It is worth knowing that every element of the brake booster system uses vacuum to function properly. Otherwise, the brake pedal will quickly become stiff and ineffective. In addition, certain elements are associated with the position of the pedal, so that they have an equivalent in the position of the brake piston. Thus, the car brakes with a force determined by the driver. In addition, a servo-driven pressure transducer is used to maintain the correct pressure throughout the entire system.

The mechanism described above is used in gasoline engines. On the other hand, diesel engines, turbocharged engines and electric vehicles also use a vacuum pump which is driven mechanically or electrically.

In the case of the brake booster, the situation is different even in trucks. In the case of such large vehicles, a more complex pressurized auxiliary braking device is used. It uses compressed air pressure.

How to detect server failure?

Most often, a malfunction of the brake booster can be recognized by a tight and difficult to press brake pedal, the stroke of which, when pressed, is significantly shortened. If you brake with the engine off, this is perfectly normal.. However, if this happens while the engine is running, you can be sure that the brake booster has failed.

It's also worth checking your brake fluid reservoir because leaks can be problematic. This indicates a leak in the system, so further driving may be associated with increased risk and reduced braking performance. Strange sounds during braking may also indicate that something is wrong with the system and you should contact a specialist. In case of damage to the brake booster, it must be replaced as a whole, as this is a maintenance-free device. Fortunately, it breaks relatively rarely, and its price is not so high.

Often the problem can also be a damaged vacuum line that loses its vacuum support properties when it leaks. Other faults related to the brake system and brake booster include a problem with a check valve, improper selection of a booster for an incorrectly sized device, and installation of a vacuum line of the wrong diameter.

How to check the condition of the brake booster?

You can test the brake booster yourself in practice. All you have to do is control the braking distance and the pressure needed to bring the car to a complete stop. Moreover, you can replace the brake booster yourself. If you notice any problems with your brake booster, invest in a new one and replace it immediately because the braking system is critical to safe driving.

You already know what a brake booster is and what this part of the brake system is for. Despite its discreet dimensions, it is an extremely important element of every car, because safety, braking efficiency and driver comfort depend on it. Without a brake booster, driving a car would be much more difficult. In addition, drivers would have a problem adapting the pressure on the brake pedal to the current conditions and requirements of a particular situation.