What is included in the diagnosis of the chassis of the car

Content

Every car owner during his car ownership is faced with diagnostics or even undercarriage repairs. Most often, diagnostics of the chassis of a car is carried out before buying a car, as well as in the event of any visible problems or as a regular check.

Checking the car's suspension consists of examining many technical components that can be checked in various ways, both with the help of special equipment, a lift, and independently, using, for example, a regular standard jack. In this article, we will consider everything that is included in the diagnosis of the chassis of a car, and you can choose what to check and how.

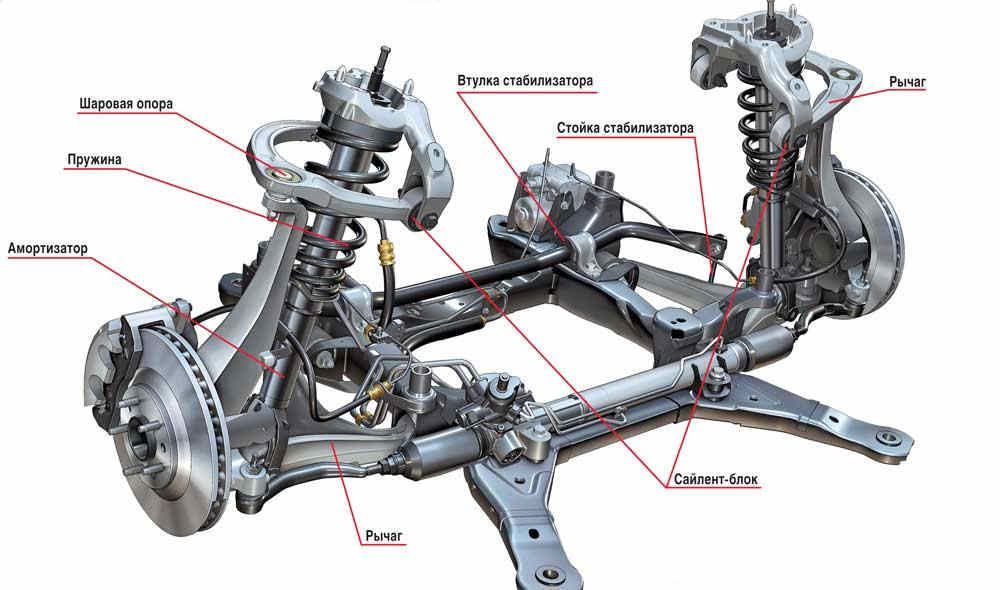

What is checked when diagnosing the chassis

- wheel bearings;

- levers (condition of silent blocks);

- ball bearings;

- brake system (hoses, calipers, pads);

- stabilizer's pole;

- torsion bars (in case torsion bar suspension);

- springs (as a rule, they are installed on the rear axles of trucks or off-road vehicles, they can also be installed on all axles).

Let's take a closer look at the diagnostics of each chassis assembly.

Hub bearings

To check the wheel bearings, it is necessary to hang the wheels (lift the car on a hoist or hang out each wheel in turn with a jack).

First, we check the bearings for play, for this we take the wheel with our hands first in the horizontal plane, and then in the vertical one and try to move it. For example, we check in a vertical plane. If the upper hand pushes away from itself, then the lower hand pulls towards itself, then vice versa. If during these movements it is felt that the wheel is loose, then this means the presence of backlash.

It is worth noting that the front wheels should be checked taking into account that during the horizontal position of the hands you can move the steering rack. In this case, it is better to test with the hands upright.

The second step in checking the bearings is to turn the wheel. We push the wheel with our hand in any direction of rotation and try to hear extraneous mechanical sounds.

Note! Very often, when turning the wheel, you can hear “short” sounds, with the frequency of the wheel turning 360 degrees. Most likely it's the brake pads rubbing against the brake discs.

This happens because the discs tend to bend during overheating (many intense braking in a row). It turns out a kind of figure eight, which, in the place of its irregularities, will touch the brake pads when rotating.

In the case of a bearing, most often, the sound will be in the form of a grinding or crunching sound.

Brake system

Any diagnostics of the brake system begins with checking the brake pads, namely their wear. In most cases, with light-alloy cast wheels installed, it is possible to check the degree of wear without resorting to disassembly. And if the discs are stamped, then you have to remove the wheel to see the thickness of the working surface of the pads.

As a rule, brake pads are enough for 10-20 thousand kilometers, depending on the operation and quality of the pads themselves.

Together with the pads, the degree of wear of the brake discs should also be checked. Each car has its own minimum disc thickness. Measurements are carried out using a caliper.

Do not forget about checking the brake hoses for wet spots, microcracks and other damage. Hoses are especially prone to crackling at bends or under the rubber bands that attach them (so as not to dangle).

Levers and silent blocks

If you did not hit hard obstacles (in winter it can often be carried to the curb) or did not fall into large road holes, then the levers themselves are most likely intact. Problems often arise with silent blocks (gaskets installed in the places where the levers are attached to the car body).

The other end of the levers, as a rule, is already connected to the hub itself, using a ball joint. It is necessary to check the silent blocks for mechanical damage, cracks. Ball joints are checked for backlash and boot integrity. In the case of a torn ball boot, it does not take long, since dirt and sand will get there.

Ball joints are checked for play with a crowbar or pry bar. It is necessary to rest against the crowbar and try to squeeze or press the ball, if you notice the ball move, this indicates the presence of a backlash.

The backlash of the steering tip is checked in the same way.

Shrus

In the case of front wheel drive vehicles, it is imperative to check if the boot is torn. If the boot is torn, dirt and sand will clog in there very quickly and it will fail. The CV joint can also be checked on the move, for this you need to completely turn the steering wheel (first we check in one direction, therefore in the other) and start moving. The failure of the CV joint can be identified by the characteristic crunch.

Shock absorbers

The shock absorbers are checked for the integrity of the lower silent block, as well as for smudges, if the shock absorber is oil. This is if you carry out diagnostics visually “by eye”. In another way, it can only be checked by dismantling it. To check, we unclench the shock absorber completely and then sharply try to compress it, if it moves slowly and smoothly, then most likely it is in order, and if jerks are noticeable during compression (dips in resistance), then such a shock absorber must be replaced.

Checking the car suspension on a vibration stand

Vibrostand is a specialized equipment that allows you to diagnose the chassis of a car and display all the results in electronic form. The stand creates various vibrations and, using a variety of sensors, measures the response of the suspension to vibrations. Chassis parameters for each car are different. For more details on the process of checking the suspension of a car on a vibration stand, see the video.

Watch this video on YouTube

Suspension Diagnostic Price

Running gear diagnostics by a master can cost you from 300 to 1000 rubles, depending on the service.

The cost of checking the suspension on a vibration stand will be higher, but the prices here vary greatly, since the services have equipment of different professional levels and set their own price for this type of diagnostics.

Questions and answers:

What is included in the vehicle chassis diagnostics? This is a whole range of works. These include checking the condition of the springs, shock absorbers, levers, steering tips and, if necessary, replacing them.

How to understand that there are problems with the chassis? While driving, the car goes to the side, body roll is observed (when it turns or slows down), the car wobbles at speed, uneven rubber wear, vibration.

How to properly check the chassis of a car? Everything under the car is subject to inspection: springs, shock absorbers, levers, ball, tips, CV joint anthers, silent blocks.