Accord 7 Knock Sensor

Content

The engine knock sensor is one of the sensors in the engine management system. Despite the relative reliability of the knock sensor on the Honda Accord 7, it sometimes fails. Consider the device and the reasons for the inoperability of the sensor, possible consequences, control methods and the sequence of replacing the sensor.

Knock sensor device Accord 7

The seventh generation Accord cars use a resonant type knock sensor. Unlike a broadband sensor that transmits the entire spectrum of engine vibrations to the control unit, resonant sensors only respond to engine speeds that are within the crankshaft speed. This has advantages and disadvantages.

A positive point is that the engine control unit should not “tend” for false alarms, for example, for high-frequency hissing of the alternator belt, and other extraneous vibrations. Also, resonant sensors have a higher amplitude of the electrical signal, which means higher noise immunity.

Negative moment - the sensor has low sensitivity at low, and, conversely, high engine speeds. This may result in the loss of important information.

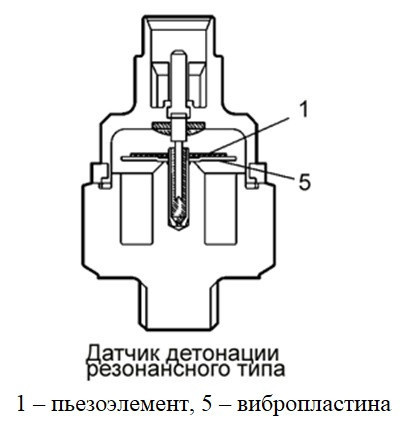

The appearance of the knock sensor Accord 7 is shown in the figure:

Knock sensor appearance

At the moment of engine detonation, vibrations are transmitted to a vibrating plate, which, resonating, repeatedly amplifies mechanical vibrations. The piezoelectric element converts mechanical vibrations into electrical vibrations that follow the engine control unit.

Sensor design

Purpose of the knock sensor

The main purpose of the engine knock sensor is to correct the ignition angle of the engine when an engine knock effect is present. Engine knock is usually associated with early starting. Early engine start is possible when:

- refueling with low-quality fuel (for example, with a lower octane number);

- wear of the gas distribution mechanism;

- incorrect setting of the ignition angle during preventive and repair work.

When a knock sensor signal is detected, the engine control unit corrects the fuel supply, reduces the ignition timing, i.e. delays the ignition, preventing the detonation effect. If the sensor does not work properly, the detonation effect cannot be avoided. This can lead to serious consequences, namely:

- a significant increase in the load on the components and mechanisms of the engine;

- malfunction of the gas distribution system;

- more serious problems to the need for engine overhaul.

Failure of the knock sensor is possible for the following reasons:

- wear;

- mechanical damage during repair work or in the event of a traffic accident.

Methods for monitoring a malfunction of the knock sensor

The main symptom of a bad knock sensor is the presence of an engine knock effect, which is felt when the accelerator pedal is pressed hard under load, such as when driving downhill or accelerating. In this case, be sure to check the performance of the sensor.

The most reliable method for determining a malfunction of the Accord 7 engine knock sensor is to conduct computer diagnostics. Error code P0325 corresponds to a knock sensor error. You can also use the parametric control method. To do this, the sensor must be removed. It is also necessary to use a highly sensitive AC voltmeter (you can use a multimeter as a last resort, setting the switch to the lower limit to measure AC voltage) or an oscilloscope to check the signal level between the case and the sensor output by making small bumps on the device.

The amplitude of the signals must be at least 0,5 volts. If the sensor is OK, you need to check the wiring from it to the engine control unit.

It is impossible to check the sensor with a simple dial tone with a multimeter.

Replacing the knock sensor with Accord 7

The knock sensor is located in an inconvenient place for replacement: under the intake manifold, to the left of the starter. You can see its location in more detail on the layout drawing.

In this figure, the sensor is shown in position 15.

Before dismantling the knock sensor, it is necessary to treat the sensor installation site with sheet metal or other special composition to remove coke, since during operation it was in an oily state at high temperatures.

A new knock sensor is inexpensive. For example, an original Japanese-made sensor under the article 30530-PNA-003 costs about 1500 rubles.

After installing a new sensor, you must reset the engine errors using a diagnostic scanner.