Oxygen sensor (Lambda probe)

Content

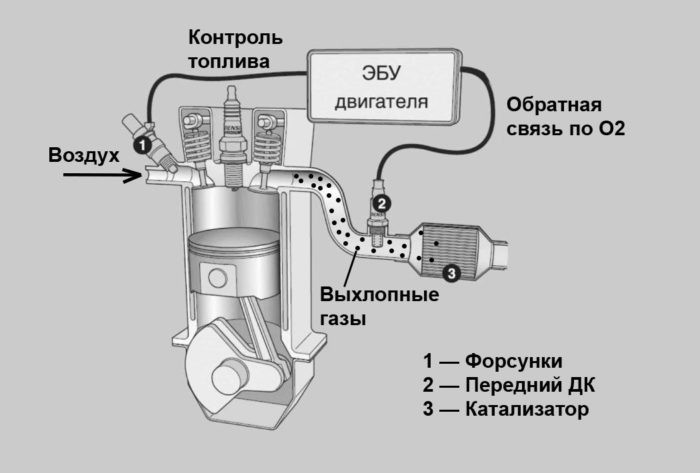

An oxygen sensor (OC), also known as a lambda probe, measures the amount of oxygen in the exhaust gases by sending a signal to the engine control unit (ECU).

Where is the oxygen sensor

The front oxygen sensor DK1 is installed in the exhaust manifold or in the front exhaust pipe before the catalytic converter. As you know, the catalytic converter is the main part of the vehicle emission control system.

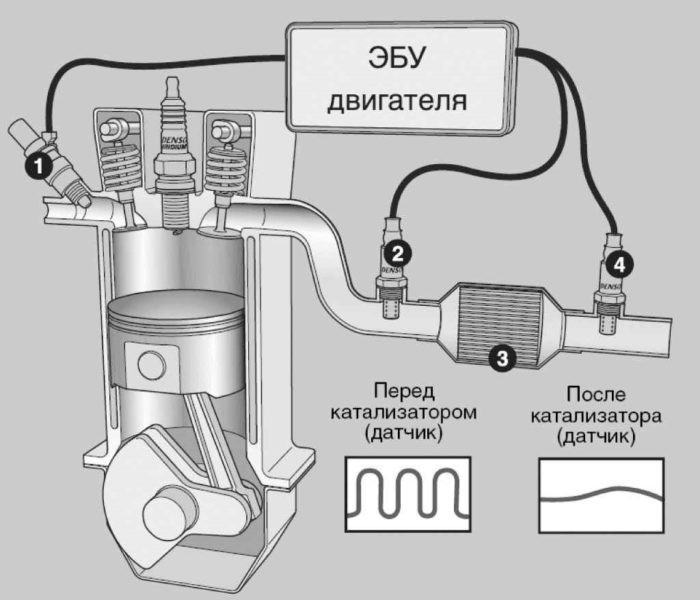

The rear lambda probe DK2 is installed in the exhaust after the catalytic converter.

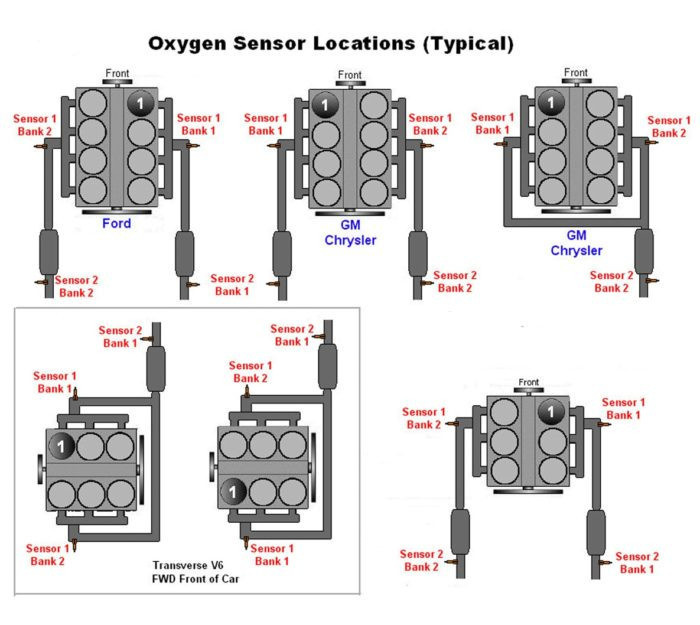

On 4-cylinder engines, at least two lambda probes are installed. V6 and V8 engines have at least four O2 sensors.

The ECU uses the signal from the front oxygen sensor to adjust the air/fuel mixture by adding or reducing the amount of fuel.

The rear oxygen sensor signal is used to control the operation of the catalytic converter. In modern cars, instead of the front lambda probe, an air-fuel ratio sensor is used. Works similarly, but with more precision.

How an oxygen sensor works

There are several types of lambda probes, but for simplicity, in this article we will only consider conventional oxygen sensors that generate voltage.

As the name suggests, a voltage generating oxygen sensor generates a small voltage proportional to the difference in the amount of oxygen in the exhaust gas and in the exhaust gas.

For proper operation, the lambda probe must be heated to a certain temperature. A typical modern sensor has an internal electrical heating element that is powered by the engine ECU.

When the fuel-air mixture (FA) entering the engine is lean (little fuel and a lot of air), more oxygen remains in the exhaust gases, and the oxygen sensor produces a very small voltage (0,1–0,2 V).

If the fuel cells are rich (too much fuel and not enough air), there is less oxygen left in the exhaust, so the sensor will generate more voltage (about 0,9V).

Air-fuel ratio adjustment

The front oxygen sensor is responsible for maintaining the optimum air/fuel ratio for the engine, which is approximately 14,7:1 or 14,7 parts air to 1 part fuel.

The control unit regulates the composition of the air-fuel mixture based on data from the front oxygen sensor. When the front lambda probe detects high oxygen levels, the ECU assumes the engine is running lean (not enough fuel) and therefore adds fuel.

When the oxygen level in the exhaust is low, the ECU assumes that the engine is running rich (too much fuel) and reduces the fuel supply.

This process is continuous. The engine computer constantly switches between lean and rich mixtures to maintain the optimum air/fuel ratio. This process is called closed loop operation.

If you look at the front oxygen sensor voltage signal, it will range from 0,2 volts (lean) to 0,9 volts (rich).

When the vehicle is cold started, the front oxygen sensor does not fully warm up and the ECU does not use the DC1 signal to regulate fuel delivery. This mode is called open loop. Only when the sensor is fully warmed up does the fuel injection system go into closed mode.

In modern cars, instead of a conventional oxygen sensor, a wide-band air-fuel ratio sensor is installed. The air/fuel ratio sensor works differently, but has the same purpose: to determine whether the air/fuel mixture entering the engine is rich or lean.

The air-fuel ratio sensor is more accurate and can measure a wider range.

Rear oxygen sensor

The rear or downstream oxygen sensor is installed in the exhaust after the catalytic converter. It measures the amount of oxygen in the exhaust gases leaving the catalyst. The signal from the rear lambda probe is used to monitor the efficiency of the converter.

The controller constantly compares the signals from the front and rear O2 sensors. Based on the two signals, the ECU knows how well the catalytic converter is working. If the catalytic converter fails, the ECU turns on the "Check Engine" light to let you know.

The rear oxygen sensor can be checked using a diagnostic scanner, an ELM327 adapter with Torque software, or an oscilloscope.

Oxygen Sensor Identification

The front lambda probe before the catalytic converter is commonly referred to as the "upstream" sensor or sensor 1.

The rear sensor installed after the catalytic converter is called the down sensor or sensor 2.

A typical inline 4-cylinder engine has only one block (bank 1/bank 1). Therefore, on an inline 4-cylinder engine, the term "bank 1 sensor 1" simply refers to the front oxygen sensor. "Bank 1 Sensor 2" - rear oxygen sensor.

Read more: What is Bank 1, Bank 2, Sensor 1, Sensor 2?

A V6 or V8 engine has two blocks (or two parts of that "V"). Typically, the cylinder block containing cylinder #1 is referred to as "bank 1".

Different car manufacturers define Bank 1 and Bank 2 differently. To find out where bank 1 and bank 2 are on your car, you can look in your repair manual or Google for the year, make, model, and size of the engine.

Replacing the oxygen sensor

Oxygen sensor problems are common. A faulty lambda probe can lead to increased fuel consumption, higher emissions and various driving problems (rpm drop, poor acceleration, rev float, etc.). If the oxygen sensor is defective, it must be replaced.

On most cars, replacing the DC is a fairly simple procedure. If you want to replace the oxygen sensor yourself, with some skill and a repair manual, it's not that difficult, but you may need a special connector for the sensor (pictured).

Sometimes it can be difficult to remove an old lambda probe, as it often rusts a lot.

Another thing to keep in mind is that some cars have been known to have issues with replacement oxygen sensors.

For example, there are reports of an aftermarket oxygen sensor causing problems on some Chrysler engines. If you're unsure, it's best to always use the original sensor.