Crankshaft sensor Nissan Primera P12

Content

If the crankshaft position sensor fails, the Nissan Primera P12 power plant starts to work unevenly, up to a complete failure to start. Therefore, the condition of the DPKV is extremely important when operating a car.

Purpose of the crankshaft sensor

The Nissan Primera R12 crankshaft sensor is used to collect information about the rotation of the crankshaft. Based on the received data, the ECU calculates the position of the pistons. Thanks to the information coming from the sensor, control commands are formed in the main module.

The entire power plant is critical to the operation of the sensor. Even a short-term lack of data on the position of the crankshaft leads to the inability of the computer to work. Without receiving commands, the speed starts to float and the diesel engine stops.

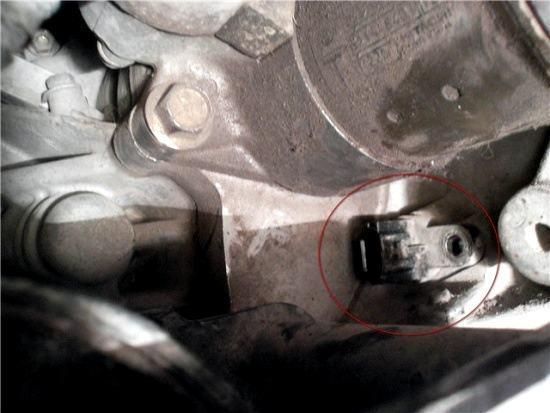

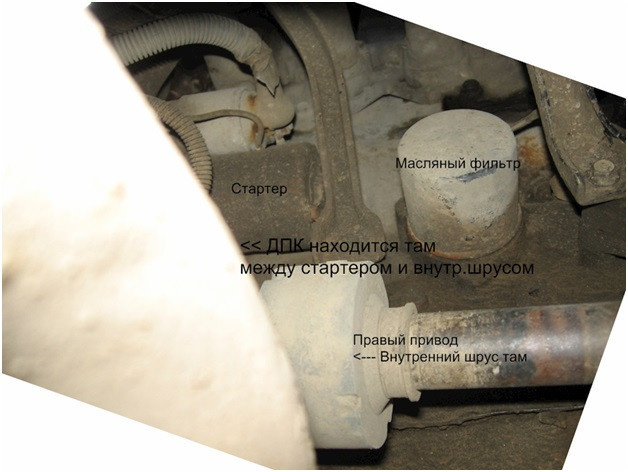

Crankshaft sensor location on Nissan Primera P12

The crankshaft position sensor is located at the rear of the cylinder block. To see where the DPKV is located, you need to crawl under the car and remove the engine protection. You can look up at the sensor. To do this, in the engine compartment, you will need to remove a number of nodes.

Sensor cost

The Primera P12 uses the original Nissan crankshaft position sensor 237318H810. Its price is 3000-5000 rubles. On sale there are analogues of the brand counter. The following table lists the best alternatives to the original DPKV in the First P12.

Table - Good analogues of the original Nissan Primera P12 crankshaft sensor

| Creator | Supplier code | Estimated cost, rub |

|---|---|---|

| Luke | SEB1723 | 1400-2000 |

| TRV | SEB1723 | 2000-3000 |

| IT WAS | 550851 | 2100-2900 |

| FAE | 79160 | 1400-2000 |

| facet | 9041 | 1200-1800 |

Crankshaft sensor test methods

If you suspect a malfunction of the crankshaft position sensor, check its performance. Start with a visual inspection. The sensor housing must not be damaged. Next, you need to inspect the contacts. They must be clean and free of any signs of oxidation.

The crankshaft and camshaft position sensors are interchangeable. At the same time, DPKV has a more significant impact on the operation of the power plant. Therefore, many car owners switch places to check and try out the engine start. The disadvantage of this method is the risk of damage to the camshaft sensor during removal.

You can check the crankshaft position sensor with a multimeter or ohmmeter. To do this, you need to measure the resistance of your winding. It should be between 550 and 750 ohms.

If the crankshaft sensor fails, an error is recorded in the computer memory. This needs to be calculated. The code obtained after decryption will indicate the presence of a particular problem with the DPKV.

Required tools

To replace the crankshaft position sensor on a Nissan Primera R12, you will need a list of tools from the table below.

Table - Tools required to replace the crankshaft sensor

| First name | Note |

|---|---|

| ring wrench | Place |

| Head | «10» |

| Vorotok | With ratchet, cardan and extension |

| Penetrating lubricant | To combat rusted threaded connections |

| Metal brush and rag | For cleaning the workplace |

It is possible to replace the crankshaft position sensor both at the bottom and at the top of the engine compartment. The first way is more preferable. To get from below, you will need an observation deck, a flyover or an elevator.

Self-replacement of the sensor on Nissan Primera P12

To replace the Primera P12 crankshaft position sensor, you must follow the step-by-step algorithm presented in the instructions below.

- Disconnect the on-board network by resetting the negative battery terminal.

- Access from below the first P12.

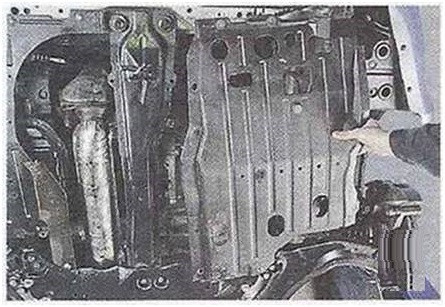

- Remove the protection of the power unit

- Remove the cross member of the subframe.

- Disconnect the crankshaft position sensor connector terminal block.

- Loosen the DPKV mounting bolt.

- Slightly rocking, remove the crankshaft position sensor from the seat.

- Check the sealing ring. When replacing an old sensor, it may harden. In this case, the ring will need to be replaced. It is also worth considering that many analogues come without sealant. In them, the ring must be installed independently.

- Install the crankshaft position sensor.

- Fix the DPKV and connect the connector.

- Reassemble everything in reverse order.

- Check the operation of the engine by starting the power plant.