Crankshaft sensor VAZ 2110

Content

- What is a crankshaft position sensor on a vase

- Features of injection systems

- A little about the master discs

- A little about the crankshaft

- Replacing chips and pinout DPKV VAZ 2110

- Signs of breakage

- Crankshaft sensor VAZ 2110 Causes of failure

- Checking the VAZ 2110 crankshaft sensor for serviceability

- Controller Diagnostics

- To change, or not to change the VAZ 2110 crankshaft sensor?

- Replacement

- Functional Testing

- Conclusion

What is a crankshaft position sensor on a vase

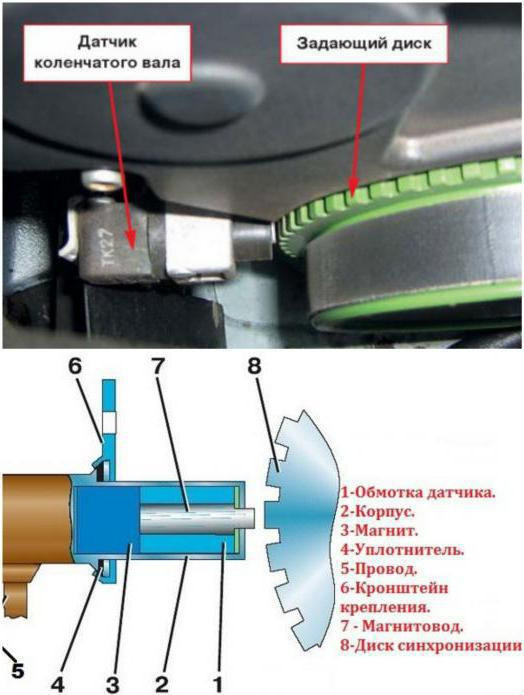

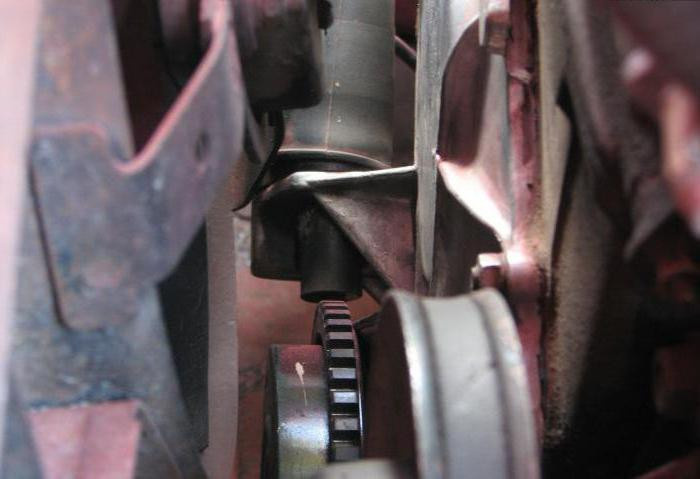

The VAZ 2110 induction crankshaft sensor is installed next to a special disk located together with the crankshaft drive pulley. A special disk is called a master or master disk. Together with it, it provides angular synchronization of the control unit. Skipping two 60 teeth on the disc allows the system to determine the TDC of the 1st or 4th cylinder. Tooth 19 after the passage should face the DPKV rod, and the mark on the camshaft should be against the curved reflector mount. The gap between the sensor and the tooth tip of the disc is in the range of 0,8 to 1,0 mm. Sensor winding resistance 880-900 Ohm. To reduce interference, the crankshaft sensor wire is shielded.

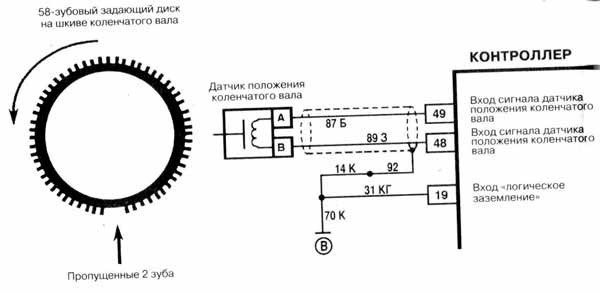

After the ignition is turned on, the control program of the unit is in the mode of waiting for a clock signal from the crankshaft position sensor. When the crankshaft rotates, a synchronizing pulse signal instantly enters the control unit, which, by its frequency, switches the electrical circuit of the injectors and ignition coil channels to ground.

The control unit program algorithm works on the principle of reading 58 teeth passing through the DPKV magnetic circuit with two missing. A jump of two teeth is a reference mark for determining the piston of the first (fourth) cylinder in the position of top dead center, from which the unit analyzes and distributes switching signals over the operating cycles of the injector engine controlled by it and the spark in the candles.

The control unit detects a momentary failure in the synchronization system and attempts to re-synchronize the control process. If it is impossible to restore the synchronization mode (lack of contact in the DPKV connector, cable breakage, mechanical damage or breakage of the drive disk), the system generates an error signal on the dashboard, including the Check Engine emergency lamp. The engine will stop and it will be impossible to start it.

The crankshaft position sensor is a reliable device and rarely fails, but sometimes breakdowns are associated with a careless or negligent attitude of engine maintenance specialists.

The crankshaft position sensor is a reliable device and rarely fails, but sometimes breakdowns are associated with a careless or negligent attitude of engine maintenance specialists.

For example, the VAZ-2112 has a 21124 engine (16-valve, where the DPKV cable is very close to the exhaust manifold), and the problem usually occurs after repair, when the cable chip is not fixed in the bracket. Upon contact with a hot pipe, the cable melts, destroying the wiring diagram, and the machine stalls.

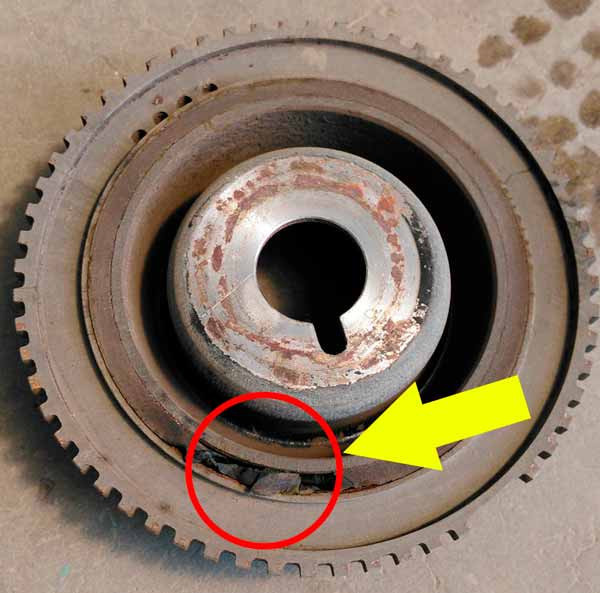

Another example would be a poorly made drive disc whose rubber bushing can rotate on an internal pivot.

The electronic control unit, upon receiving a single signal from the DPKV, determines the position relative to the crankshaft at each moment of time, calculating its rotational speed and angular velocity.

Based on the sinusoidal signals generated by the crankshaft position sensor, a wide range of tasks is solved:

- Determine the current position of the piston of the first (or fourth) cylinder.

- Check the moment of fuel injection and the duration of the open state of the injectors.

- Control of the ignition system.

- Management of the variable valve timing system;

- Management of the fuel vapor absorption system;

- Ensure the operation of other additional systems related to the engine speed (for example, electric power steering).

Thus, the DPKV ensures the operation of the power unit, determining with high accuracy the operation of its two main systems: ignition and fuel injection.

Before buying a replacement DPKV, it is necessary to clarify the type of device installed on the engine.

Functions and purpose Crankshaft sensor VAZ 2110

In an engine with 8 or 16 valves, the DPKV is designed to perform uncontrolled options, but to synchronize phases for gasoline injection. Also, the crankshaft sensor on the VAZ 2110 transmits an impulse to ignite the air-fuel mixture in the combustion chambers of the power unit. Therefore, if the controller fails, this can lead to the fact that various vehicle systems will not work correctly. And this means that the normal operation of the engine will be impossible.

Crankshaft sensor VAZ 2112

The VAZ 2110 crankshaft sensor itself is an inductive type device; this controller must respond to the passage of teeth on the drive disk. This disk is mounted on the drive pulley of the generator, and the controller itself is installed next to it. There are 58 teeth on the pulley, between which there is a cavity the size of 2 teeth. This cavity provides synchronization with the top dead center of the engine pistons. At the moment the cavity passes through the controller, a corresponding signal is sent to the engine control unit.

There are quite a few designs of such devices, the principle of their operation is based on such a regulator as the VAZ 2110 Hall sensor. In the latter case, the regulator also responds to a rotating shaft, but its operation is carried out as a result of the passage of a permanent magnet.

Inductive (magnetic) crankshaft sensor VAZ 2110

The device is based on a magnetized core placed in a coil. At rest, the magnetic field is constant and there is no self-induction EMF in its winding. When the top of the metal tooth of the driving disk passes in front of the magnetic circuit, the magnetic field around the core changes, which leads to the induction of a current in the winding. When the disc rotates, an alternating current appears at the output, while the frequency of the current varies depending on the speed of rotation of the shaft. The work is based on the effect of electromagnetic induction.

A feature of this sensor is its simple design, which works without an additional power source.

Hall effect sensor

The type of these sensors works on a microcircuit placed in a housing with a magnetic circuit, and the setting disk creates a moving magnetic field with magnetized teeth.

The sensor provides high-precision signal output in all specified modes of rotation of the crankshaft. The Hall sensor requires a DC voltage connection.

Optical sensors

It is based on the physical phenomenon of the photoelectric effect. Structurally, it is a light source with a receiver (photodiode). Rotating between the source and the receiver, the perforated disk periodically closes and opens the path to the light source, as a result, the photodiode generates a pulsed current, which enters the control unit in the form of an analog signal (the system has a limited application and was previously installed in injection car distributors, for example, Matiz).

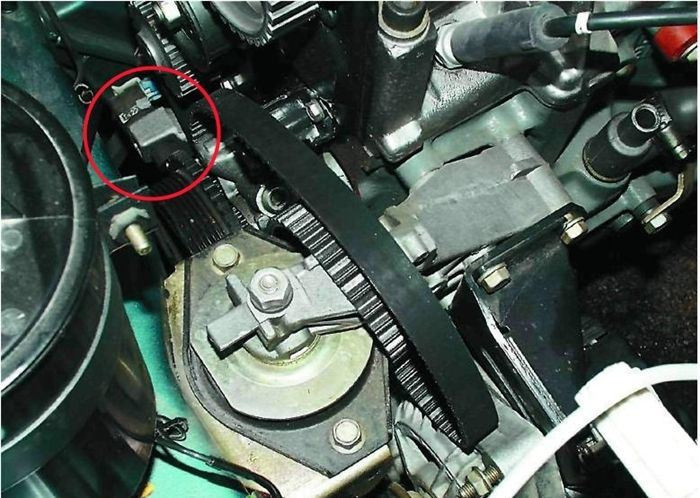

Where is the VAZ 2110 crankshaft sensor located?

If engine malfunctions are noted, then before proceeding with the identification of breakdowns and signs of malfunctions, it is necessary to find out where the regulator is located. Where is the crankshaft position sensor on the 8 or 16 valve ten? If you open the hood you will notice that the regulator is right on the oil pump cover. As you can see, the location of the regulator is not very convenient. At that time, VAZ engineers thought about the advisability of replacing the controller, so they equipped the DPKV with an 80 cm long cable.

Location of the DPKV under the hood of the car

What car is the crankshaft position sensor from?

| Model | Engine code | Year | Volume engine l. |

|---|---|---|---|

| 110 (2110) 1,5 | BA3 2111 / VAZ-2111 | 1995 - 2005 years | 1,5 |

| 110 (2110) 1,5 16V | VAZ-2112 | 1995 - 2010 years | 1,5 |

| 110 (2110) 2.0i | C20XE | 1996 - 2000 years | two |

| 110 (2110) Wankel | VAZ-415 | 1997 - 2004 years | 2,6 |

| 110 (2110) 1,6 | VAZ-21114 / VAZ-21124 | 1995 - 2012 years | 1,6 |

| 110 (2110) 1,6 16V | VAZ-21124 | 2004 - 2010 years | 1,6 |

| 110 (2110) 1,6 HBO | VAZ-21114 | 2004 - 2007 years | 1,6 |

| 111 (2111) 1,5 | VAZ-2111/BA3 2111 | 1996 - 2005 years | 1,5 |

| 111 (2111) 1,5 16V | VAZ-2112 | 1995 - 2005 years | 1,5 |

| 111 (2111) 1,6 | VAZ-21114 / VAZ-21124 | 2004 - 2013 years | 1,6 |

| 112 (2112) 1,5 | VAZ-2111 | 1995 - 2005 years | 1,5 |

| 112 (2112) 1,5 16V | VAZ-2112 | 1995 - 2005 years | 1,5 |

| 112 (2112) 1,6 | VAZ-21124 / VAZ-21114 | 2005 - 2011 years | 1,6 |

Features of injection systems

The injection system works thanks to a sensor system and a control unit. All signals are fed to the input of the microprocessor unit that regulates the operation of the actuators. The following sensors are responsible for the correct operation of the engine:

- Crankshaft positions.

- Camshaft positions (not on all versions).

- pressure in the intake manifold.

- The Lambda probe.

- Speeds.

- Mass air flow.

- Throttle positions.

And the main role is played by the VAZ-2110 crankshaft sensor (8 valves or 16), since the moment of injection and the supply of high voltage to the electrodes of the candles depend on it. There is a temperature sensor in the design, but it practically does not affect the operation. It is necessary to monitor the temperature of the engine and give a signal to the arrow (or to the on-board computer). But it will be indispensable if it is necessary to implement an automatic change of fuel types (from gasoline to gas and vice versa).

Algorithm of the injection system

The microprocessor has several inputs and outputs. The inputs receive signals from all sensors. But first, these signals are converted, if necessary, amplified. The microcontroller is programmed to work with sensors and actuators. Programs (firmware) can provide various engine functions.

You can achieve an increase in power (gasoline consumption will increase) or a decrease in consumption (power will suffer). But most motorists prefer programs that provide work with average parameters. At the same time, the signal of the VAZ-2110 crankshaft position sensor does not change, only the reaction of the actuators to the change in input data is corrected.

A little about the master discs

Adjusting discs for inductive sensors are made of steel, sometimes integral with the crankshaft pulley (for example, an Opel car).

The disks for Hall sensors are made of plastic, and permanent magnets are pressed into their teeth.

A little about the crankshaft

The crankshaft is the most important element of any internal combustion engine. It is driven by a starter motor (during start-up) and pistons (during operation). From there, the torque is transmitted to the gearbox, gas distribution system and auxiliary mechanisms. And in order for fuel injection to occur in a timely manner, a spark was formed at the right time, a VAZ-2110 crankshaft sensor is needed.

It monitors the position of the pulley and transmits a signal to the electronic control unit. There are teeth on the pulley, the distance between them is the same. But in one place a pass - two teeth are missing. The position sensor reacts to the approach of metal. When an empty area passes near the sensor, a signal is generated - the control unit is notified that one revolution of the crankshaft has occurred.

Replacing chips and pinout DPKV VAZ 2110

Over time, the wires leading to the DPKV chip wear out. It is located at the bottom of the engine and not far from the front wheel, as a result, dirt, snow, oil, chemical aggressive environments in the form of salts are deposited on the DPKV and its chip, which leads to slow oxidation of the wires on the microcircuit and after they break. Since the wires of the microcircuit are combined into one package, when replacing it, a repair microcircuit is provided with two protruding wires 15 cm long. After removing the damaged microcircuit, install a new one in the “coil”. The twisting points are insulated with heat shrink or electrical tape.

You can see in the diagram below that its pin assignment is straightforward, with two wires connected directly to the signal input pins on the control box running the length of the case. Observe the polarity of connecting the sensor signal cables to the control unit. If the polarity is reversed, the synchronization system will not work. To restore the operation of the DPKV, you only need to change the cables and check the performance by starting the engine.

Signs of breakage

Any malfunction of the VAZ 2110 crankshaft sensor will make it impossible to start the engine after a long stop. If the controller starts to fail during vehicle operation, in 90% of cases the engine will stop, since the ECU will not generate a signal to the ignition system, the internal combustion engine safety function will work. Signs of a sensor malfunction when the assembly begins to break:

- check Engine is activated on the dashboard;

- engine speed becomes unstable, thrust decreases by 50;

- the VAZ 2110 crankshaft sensor should be urgently changed when the following symptom of a malfunction appears: with an increase in speed, a dull noise is felt in the engine area and a knock;

- the injection engine is characterized by the appearance of pops in the area of \uXNUMXb\uXNUMXbthe exhaust tract.

When the VAZ 2110 dpkv is completely out of order, the engine stalls because the computer does not give signals for the formation of a spark.

These symptoms do not always indicate that a complete replacement of the VAZ 2110 crankshaft sensor is necessary, since all element malfunctions are conventionally divided into four groups:

- surface contamination;

- damage to the winding of the device and violation of its integrity;

- manufacturing defects;

- open circuit or short circuit.

Checking the sensor begins with cleaning the part. The cleanliness of the contacts is checked, their safety, the cleanliness of the connector, oil streaks are removed. The design of the sensor is quite simple, but 20 percent of device failures are due to manufacturing defects. The break in the wiring is eliminated after the bell is closed. The VAZ 2110 crankshaft sensor is not repaired, since the cost of the consumable does not exceed 100 rubles, the assembly changes to a similar one after a little diagnostics.

Crankshaft sensor VAZ 2110 Causes of failure

There are several reasons why the sensor may fail, but they still exist.

- Mechanical damage;

- Aging;

- Electrical damage;

- Open circuit control;

Let's consider each of the failure options in more detail.

Mechanical damage This can be caused by any impact on the sensor. For example, when trying to disassemble the sensor, such breakdowns are possible.

Aging. Often in older cars, the sensor can fail due to its aging and demagnetization of the core.

electrical damage. With such a failure, the coil inside the sensor most often breaks, and the signal to the computer ceases to flow through it.

Break in the control circuit. An open control circuit is not a sensor malfunction. In the event of a break, the wiring that transmits the signal from the sensor to the computer suffers.

Checking the VAZ 2110 crankshaft sensor for serviceability

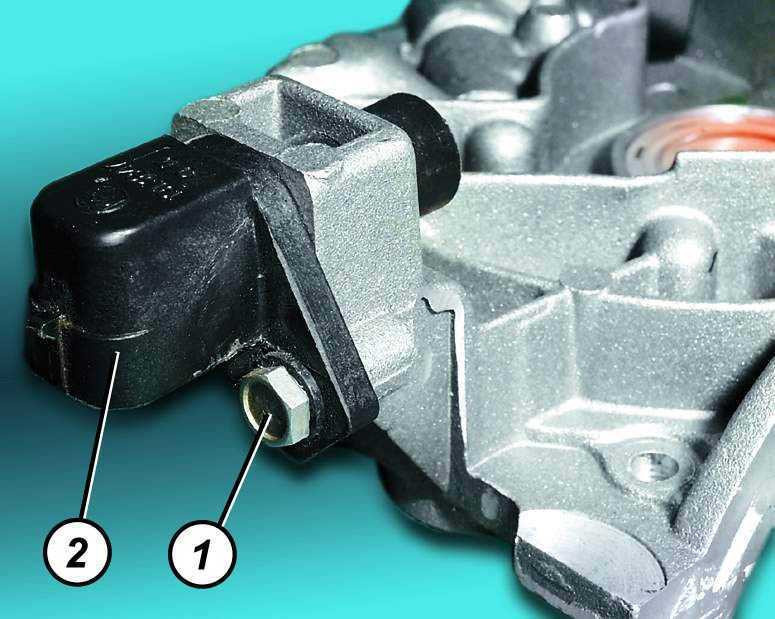

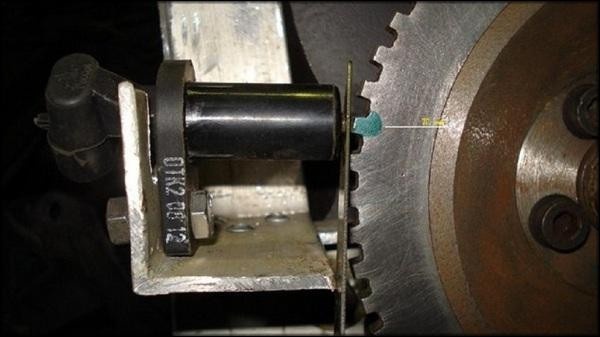

To check the alleged malfunction of the crankshaft sensor, the two most likely cases of its malfunction are considered. In both cases, you will need to disassemble the device with a ten-wire key. Before operation, marks are applied on the crankcase and on the sensor itself, which will later help to screw the device to the original angle of rotation.

In addition, before disassembling, the driver must not forget to measure the gap between the timing disk and the sensor, which cannot exceed 0,6-1,5 mm. In the absence of mechanical damage in the form of scratches, dents, damage to the structure of the material, the sensor is checked by other measuring instruments:

- ohmmeter check. In this case, it is necessary to measure the resistance of the sensor winding. Since the standard value of this indicator, set by the manufacturer, is in the range from 550 to 750 ohms, exceeding the specified limits indicates a malfunction of this instrument, which is important for the correct operation of the car, and therefore its malfunction. It is worth noting here that the manufacturer still allows a slight discrepancy between the resistances and the passport values, but in any case, they must correspond to the data specified in the machine's operating instructions;

- checking with a voltmeter, inductance meter and transformer. This method is more complicated, but more effective: the resistance is measured with the same ohmmeter, after which the inductance is checked (it should be from 200 to 4000 millihenries), with a sensor winding voltage of 500 volts. Next, you need to measure the resistance with a megger and make sure that it does not exceed 20 MΩ.

If the sensor still fails these tests, it should be replaced. With this procedure, one should not forget about the distance regulated by the manufacturer between it and the synchronization disk, as well as alignment with the marks on the crankcase that were made on the previous device. Before installing a new sensor, it should be checked, because even if all installation procedures are followed correctly, it may not work correctly.

A new DPKV is checked in the same way as a suspected malfunction, and depending on the results of the check, the device may be installed instead of the old one or defective. During installation, the bolts are tightened with a torque of 8 to 12 Nm. However, in any case, before carrying out all the steps to replace a rather expensive and hard-to-reach node, you must definitely make sure that it is he who has failed, because a car manufactured by our auto industry can often bring unpleasant surprises

The first way to check the crankshaft sensor VAZ 2110

In this case, you will need an ohmmeter, with which you will replace the resistance in the winding. According to the manufacturer's standards, the indicator is from 550 to 750 ohms.

It's okay if your indicators are slightly different from the norm. If the deviations are serious, then the sensor will definitely have to be replaced.

In fairness, it should be noted that the crankshaft position sensor on VAZ 2110 models rarely breaks. Among the main reasons for its refusal of normal functionality are the accumulation of dirt, mechanical damage and a banal factory defect.

Features of checking for other cars

As for other cars, for example, VAZ-2109 with an injection engine, VAZ-2112 and VAZ-2114, their check is carried out identically to the VAZ-2110 car.

It is noteworthy that for VAZs, when checking the resistance of the crankshaft sensor coil, an additional check can be performed.

But for this, the multimeter must be switched to voltmeter mode with a measurement limit of 200 mV.

By connecting the probes to the DPKV terminals and holding it with any metal object, such as a screwdriver, at a short distance from the core.

If the sensor is working, then it will react to the metal, the multimeter will show voltage surges on the screen. The absence of these bursts will indicate a malfunction of the element.

As for a car like Renault Logan, the difference from the VAZ in this car comes down to slightly different readings of the resistance of the sensor coil when measured with an ohmmeter.

A maintainable DPKV Logan has a normal resistance of 200-270 ohms.

For Daewoo Lanos, the coil resistance should be in the range of 500-600 ohms.

But for the ZMZ-406 engine, installed on Volga and Gazelle cars, the coil resistance is normally in the range of 850-900 Ohms.

The second method

Here you will need a voltmeter, transformer and inductance meter. It is desirable to measure resistance in compact temperature conditions.

When the ohmmeter readings are obtained, arm yourself with a device for measuring inductance. Typically, the device should display between 200 and 4000 units (millihenries).

Resistance is measured with a megohmmeter at a winding voltage of the crankshaft position sensor of 500 volts. Under normal conditions, readings will not exceed 20 MΩ.

Controller Diagnostics

Diagnostics of the crankshaft position sensor is carried out on a disassembled controller. Before disassembly, it is recommended to put a setting mark on the crankcase so that when installing a new element, the correct gap between the follower and the timing disk is maintained. Permissible gap 0,6–1,5 mm.

We remove the element with a key of 10, we carry out a visual inspection. Before checking the crankshaft sensor, the battery is disconnected, the contact points are checked. During a visual inspection, the integrity of the box, cable, connector is checked, the absence of cracks and dents on the box. In the absence of signs of mechanical damage, the DPKV is checked with a multimeter.

Checking the node can be carried out both in terms of resistance and voltage. The resistance test is much simpler, therefore it is used in most diagnostic options.

The resistance in the working winding of the controller must be in the range from 550 to 750 ohms. Measurements are made in two contacts of the part. For a 16-valve injection engine, a resistance deviation of 5% is considered acceptable.

Drivers rarely use the second test option, although diagnostics using a voltmeter are considered more reliable. To check, you will need a transformer and an inductance meter, for example, a multimeter model MY-6243 is often used to measure capacitance and inductance. Step by step verification.

- Calculate the inductance dpkv. A working element with a voltage of at least 500 mV will show an inductance in the range from 200 to 4000 hH.

- Check the resistance, a good sensor shows a parameter of 20 mOhm.

To change, or not to change the VAZ 2110 crankshaft sensor?

Let's make a reservation right away - before deciding to replace the DPKV, you need to check:

- The state of the wiring going to the DPKV;

- The presence of high-quality contacts in the circuit;

- Does not damage the cable insulation;

- No oil from crankshaft position sensor. Since there is an oil pump near the DPKV, oil leakage can also cause a malfunction.

good crankshaft position sensor

If everyone has already examined, then you need to check the sensor itself. But for this it needs to be removed.

Replacement

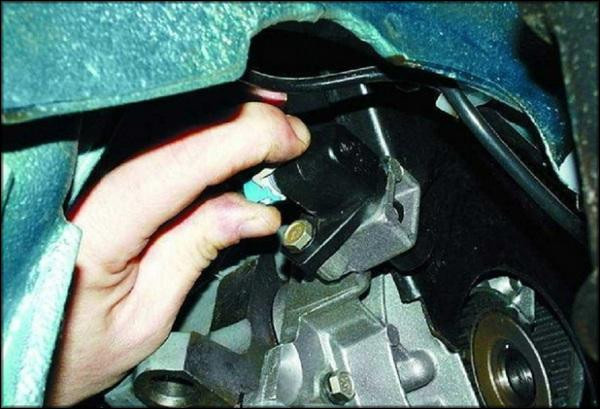

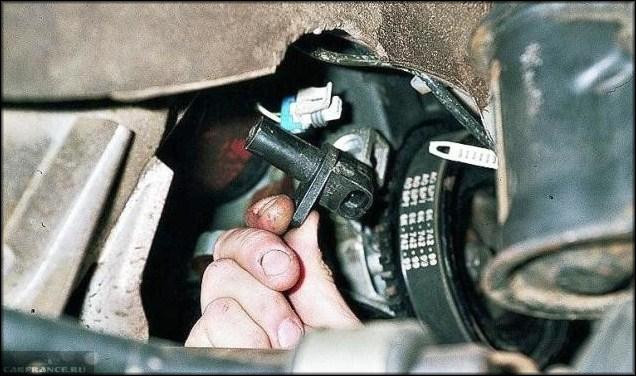

If the symptoms of a DPKV malfunction are associated with damage to the device, it is changed without repair. Drivers are located in an inconvenient place, they are attached to the oil pump cover with one bolt. How to remove an element step by step.

- The ignition is turned off, the negative terminal of the battery is removed.

- The oil pump is determined where the sensor is located, the connector is removed. An 80 cm cable goes from the controller to the unit, you can determine the location of the connector by the cable.

- The key to "10" unscrews the only screw.

- The device has been removed.

Before installing a new element, it is necessary to thoroughly clean the sensor seat and the connector plug, check the integrity of the wiring. This will prevent a quick breakage of the new part.

If the problem in the operation of the internal combustion engine is due to the absence of a signal from the sensor connector in the computer, the integrity of the wiring is checked. Electronic diagnostics, if there is a signal, but there is no response from the electronic unit, is carried out in a specialized workshop. In 90% of cases, a flashing of the control system and replacement of electronic units is required.

In half the cases, the sensor fails due to banal dirt. The controller is located very close to the oil pump, which can throw out drops of liquid. Oil, falling on the reading element of the sensor, clogs the surface, oxidizes and prevents complete data transfer.

Functional Testing

To check if the crankshaft position sensor is working, it is necessary to measure the resistance of its windings with an ohmmeter or multimeter. Normal readings are between 550 and 570 ohms.

If they differ from these numbers, then a replacement with a new one is needed. The old one cannot be repaired, but it is cheap and it is easy to replace it, following the reverse removal algorithm.

Conclusion

In the event that the VAZ-2110 crankshaft sensor (16 or 8 valves) did not pass the test, we can talk about its failure. It is advisable to check a new device before installation, at least measure the resistance. Only after making sure that it is in good condition, you can install it on the car. Be sure to check the gap between the sensor and the pulley teeth; the correct operation of the control system depends on this.

If the problem persists, try checking other sensors:

VAZ 2110 speed sensor

Oil pressure sensor VAZ 2110