ICE detonation - causes and consequences

Content

Internal combustion engine detonation can lead to serious wear of such parts of the internal combustion engine as the cylinder head gasket, elements of the cylinder-piston group, pistons, cylinders and other parts. All this significantly reduces the resource of the power unit up to its complete failure. If this harmful phenomenon occurs, it is necessary to diagnose the cause of the detonation as soon as possible and get rid of it. How to do it and what to pay attention to - read on.

What is detonation

Detonation is a violation of the combustion process of the fuel mixture in the combustion chamber, when combustion does not occur smoothly, but explosively. At the same time, the speed of propagation of the blast wave increases from standard 30 ... 45 m/s to supersonic 2000 m/s (exceeding the speed of sound by the blast wave is also the cause of the clap). In this case, the combustible-air mixture explodes not from a spark coming from a candle, but spontaneously, from high pressure in the combustion chamber.

Naturally, a powerful blast wave is very harmful to the walls of the cylinders, which overheat, the pistons, the cylinder head gasket. The latter suffers the most and in the process of detonation, the explosion and high pressure corny burn it (in slang it is called “blows out”).

Detonation is characteristic of ICEs running on gasoline (carburetor and injection), including those equipped with gas-balloon equipment (HBO), that is, running on methane or propane. However, most often it appears precisely in carbureted machines. Diesel engines work in a different way, and there are other reasons for this phenomenon.

Causes of detonation of the internal combustion engine

As practice shows, most often detonation appears on old carburetor ICEs, although in some cases this process can also occur on modern injection engines equipped with an electronic control unit. Reasons for detonation may include:

- Excessively lean fuel-air mixture. Its composition can also ignite before a spark enters the combustion chamber. At the same time, high temperatures provoke the occurrence of oxidative processes, which are the cause of the explosion, that is, detonation.

- Early ignition. With an increased ignition angle, the ignition processes of the air-fuel mixture also begin before the piston hits the so-called top dead center.

- Using the wrong fuel. If gasoline with a lower octane rating was poured into the car's tank than the manufacturer prescribes, then the detonation process is likely to occur. This is explained by the fact that low-octane gasoline is more chemically active and enters into chemical reactions faster. A similar situation will occur if, instead of high-quality gasoline, some kind of surrogate like condensate is poured into the tank.

- High compression ratio in the cylinders. In other words, coking or other contamination in the internal combustion engine cylinders, which gradually accumulates on the pistons. And the more soot is in the internal combustion engine - the higher the likelihood of detonation in it.

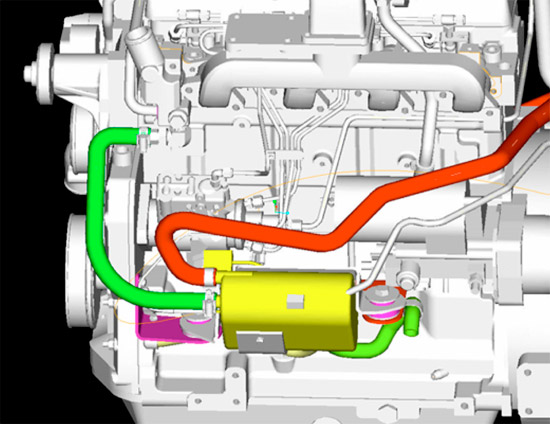

- Faulty internal combustion engine cooling system. The fact is that if the internal combustion engine overheats, then the pressure in the combustion chamber can increase, and this, in turn, can cause fuel detonation under appropriate conditions.

The knock sensor is like a microphone.

These are common reasons that are characteristic of both carburetor and injection ICEs. However, the injection internal combustion engine may also have one reason - the failure of the knock sensor. It provides the appropriate information to the ECU about the occurrence of this phenomenon and the control unit automatically changes the ignition angle in order to get rid of it. If the sensor fails, the ECU will not do this. At the same time, the Check Engine light on the dashboard is activated, and the scanner will give an engine knock error (diagnostic codes P0325, P0326, P0327, P0328).

Currently, there are many different options for flashing the ECU in order to reduce fuel consumption. However, their use is not the best solution, since there are often cases when such a flashing led to sad consequences, namely, incorrect operation of the knock sensor, that is, the ICE control unit simply turned it off. Accordingly, if detonation does occur, then the sensor does not report this and the electronics do nothing to eliminate it. also in rare cases, damage to the wiring from the sensor to the computer is possible. In this case, the signal also does not reach the control unit and a similar situation occurs. However, all these errors are easily diagnosed using the error scanner.

there are also a number of objective factors affecting the appearance of detonation in individual ICEs. namely:

- The compression ratio of the internal combustion engine. Its significance is due to the design features of the internal combustion engine, so if the engine has a high compression ratio, then theoretically it is more prone to detonation.

- The shape of the combustion chamber and piston crown. This is also a design feature of the motor, and some modern small but powerful internal combustion engines are also prone to detonation (however, their electronics control this process and detonation in them is rare).

- Forced engines. They usually have a high combustion temperature and high pressure, respectively, they are also prone to detonation.

- Turbo motors. Similar to the previous point.

As for detonation on diesel ICEs, the reason for its occurrence may be the fuel injection advance angle, the poor quality of diesel fuel, and problems with the internal combustion engine cooling system.

also the operating conditions of the car can be the cause of detonation. namely, the internal combustion engine is more susceptible to this phenomenon, provided that the car is in high gear, but at low speed and engine speed. In this case, a high degree of compression takes place, which can provoke the appearance of detonation.

Also, some car owners seek to reduce fuel consumption, and for this they reflash the ECU of their cars. However, after this, a situation may arise when a poor air-fuel mixture reduces the dynamics of the car, while the load on its engine increases, and at increased loads there is a risk of fuel detonation.

What causes are confused with detonation

There is such a thing called "heat ignition". Many inexperienced drivers confuse it with detonation, because with glow ignition, the internal combustion engine continues to work even when the ignition is turned off. In fact, in this case, the air-fuel mixture ignites from the heated elements of the internal combustion engine and this has nothing to do with detonation.

also one phenomenon that is mistakenly considered the cause of detonation of the internal combustion engine when the ignition is off is called dieseling. This behavior is characterized by a short operation of the engine after the ignition is turned off at an increased compression ratio or the use of fuel that is inappropriate for detonation resistance. And this leads to spontaneous ignition of the combustible-air mixture. That is, ignition occurs as in diesel engines, under high pressure.

Signs of detonation

There are a number of signs by which it can be indirectly determined that detonation occurs in the internal combustion engine of a particular car. It’s worth mentioning right away that some of them may indicate other breakdowns in the car, but it’s still worth checking for detonation in the motor. So the signs are:

- The appearance of a metallic sound from the internal combustion engine during its operation. This is especially true when the engine is running under load and / or at high speeds. The sound is very similar to that which occurs when two iron structures hit each other. This sound is just caused by the blast wave.

- ICE power drop. Usually, at the same time, the internal combustion engine does not work stably, it can stall when idling (relevant for carburetor cars), it picks up speed for a long time, the car’s dynamic characteristics decrease (it does not accelerate, especially if the car is loaded).

Diagnostic scanner Rokodil ScanX for connection to the car ECU

Immediately it is worth giving signs of failure of the knock sensor. As in the previous list, signs may indicate other breakdowns, but for injection machines it is better to check the error using an electronic scanner (it is most convenient to do this with a multi-brand scanner Rokodil ScanX which is compatible with all cars from 1993 onwards. and allows you to connect to a smartphone on iOS and Android via Bluetooth). Such a device will make it possible to see the performance of the knock sensor and others in real time.

So, signs of failure of the knock sensor:

- unstable operation of the internal combustion engine at idle;

- a drop in engine power and, in general, the dynamic characteristics of the car (accelerates weakly, does not pull);

- increased fuel consumption;

- difficult start of the internal combustion engine, at low temperatures this is especially noticeable.

In general, the signs are identical to those that appear with late ignition.

Consequences of detonation

As mentioned above, the consequences of detonation in the internal combustion engine of a car are very serious, and in no case should repair work be delayed, because the longer you drive with this phenomenon, the more damage the internal combustion engine and its individual elements are susceptible to. So, the consequences of detonation include:

- Burnt cylinder head gasket. The material from which it is made (even the most modern ones) is not designed to work in conditions of high temperature and high pressure that occur during the detonation process. Therefore, it will fail very quickly. A broken cylinder head gasket will cause other troubles.

- Accelerated wear of the elements of the cylinder-piston group. This applies to all of its elements. And if the internal combustion engine is no longer new or it has not been overhauled for a long time, then this can end very badly, up to its complete failure.

- Breakdown of the cylinder head. This case is one of the most difficult and dangerous, but if you drive for a long time with detonation, then its implementation is quite possible.

Burnt cylinder head gasket

Piston damage and destruction

- Piston/Pistons Burnout. namely, its bottom, lower part. At the same time, it is often impossible to repair it and it will only need to be changed completely.

- Destruction of jumpers between rings. Under the influence of high temperature and pressure, they can collapse one of the very first among other parts of the internal combustion engine.

Breakdown of the cylinder head

Piston burning

- Connecting rod bend. Here, similarly, in the conditions of an explosion, its body can change its shape.

- Burning of valve plates. This process happens very quickly and has unpleasant consequences.

Consequences of detonation

Piston burnout

As can be seen from the list, the consequences of the detonation process are the most serious, therefore, the internal combustion engine should not be allowed to work in its conditions, respectively, repairs must be made as quickly as possible.

How to remove detonation and methods of prevention

The choice of detonation elimination method depends on the reason that caused this process. In some cases, in order to get rid of it, you have to perform two or more actions. In general, the methods of combating detonation are:

- Use of fuel with parameters recommended by the automaker. namely, it concerns the octane number (you can not underestimate it). you need to refuel at proven gas stations and not fill any surrogate into the tank. By the way, even some high-octane gasolines contain gas (propane or another), which unscrupulous manufacturers pump into it. This increases its octane number, but not for long, so try to pour quality fuel into your car's tank.

- Install a later ignition. According to statistics, ignition problems are the most common cause of detonation.

- decarbonize, clean the internal combustion engine, that is, make the volume of the combustion chamber normal, without carbon deposits and dirt. It is quite possible to do it yourself in a garage, using special tools for decarbonizing.

- inspect the engine cooling system. namely, check the condition of the radiator, pipes, air filter (replace it if necessary). also do not forget to check the level of antifreeze and its condition (if it has not changed for a long time, then it is better to change it).

- Diesels need to correctly set the fuel injection advance angle.

- operate the car correctly, do not drive in high gears at low speed, do not reflash the computer in order to save fuel.

As preventive measures, it can be advised to monitor the condition of the internal combustion engine, periodically clean it, change the oil in time, perform decarbonization, and prevent overheating. Similarly, maintain the cooling system and its elements in good condition, change the filter and antifreeze in time. also one trick is that periodically you need to let the internal combustion engine run at high speeds (but without fanaticism!), you need to do this in neutral gear. At the same time, various elements of dirt and debris fly out of the internal combustion engine under the influence of high temperature and load, that is, it is cleaned.

Detonation usually occurs on a hot ICE. In addition, it is more likely on motors that are operated at minimal loads. This is due to the fact that they have a lot of soot on the pistons and cylinder walls with all the ensuing consequences. And usually the internal combustion engine detonates at low speeds. Therefore, try to operate the motor at medium speeds and with medium loads.

Separately, it is worth mentioning the knock sensor. The principle of its operation is based on the use of a piezoelectric element, which translates the mechanical effect on it into an electric current. Therefore, it is quite easy to check its work.

First method - using a multimeter operating in the mode of measuring electrical resistance. To do this, you need to disconnect the chip from the sensor, and connect the multimeter probes instead. The value of its resistance will be visible on the screen of the device (in this case, the value itself is not important). then, using a wrench or other heavy object, hit the DD mounting bolt (however, be careful, do not overdo it!). If the sensor is working, then it will perceive the impact as a detonation and change its resistance, which can be judged by the readings of the device. After a couple of seconds, the resistance value should return to its original position. If this does not happen, the sensor is faulty.

The second method verification is simpler. To do this, you need to start the internal combustion engine and set its speed somewhere at the level of 2000 rpm. Open the hood and use the same key or a small hammer to hit the sensor mount. A working sensor should perceive this as detonation and report this to the ECU. After that, the control unit will give a command to reduce the speed of the internal combustion engine, which can be clearly heard by ear. Similarly, if this does not happen, the sensor is faulty. This assembly cannot be repaired, and it only needs to be changed entirely, fortunately, it is inexpensive. Please note that when installing a new sensor on its seat, it is necessary to ensure good contact between the sensor and its system. Otherwise, it will not work correctly.