Diagnostics and repair of car frames

In this article, we will take a closer look at the options for diagnosing and repairing road vehicle frames, in particular, options for aligning frames and replacing frame parts. We will also consider motorcycle frames - the possibility of checking the dimensions and repair techniques, as well as repairing the supporting structures of road vehicles.

In this article, we will take a closer look at the options for diagnosing and repairing road vehicle frames, in particular, options for aligning frames and replacing frame parts. We will also consider motorcycle frames - the possibility of checking the dimensions and repair techniques, as well as repairing the supporting structures of road vehicles.

In almost every road traffic accident, we are accordingly faced with damage to the body. road vehicle frames. However, in many cases, damage to the vehicle frame also occurs due to improper operation of the vehicle (for example, starting the unit with a rotated steering axle of the tractor and simultaneous jamming of the tractor frame and semi-trailer due to lateral uneven terrain).

Road vehicle frames

Frames of road vehicles are their supporting part, the task of which is to connect and maintain in the required relative position of individual parts of the transmission and other parts of the vehicle. The term "frames of road vehicles" is currently most often found in vehicles with a chassis with a frame, which mainly represent a group of trucks, semi-trailers and trailers, buses, as well as a group of agricultural machinery (combines, tractors), as well as some off-road cars. road equipment (Mercedes-Benz G-Class, Toyota Land Cruiser, Land Rover Defender). The frame usually consists of steel profiles (mainly U- or I-shaped and with a sheet thickness of about 5-8 mm), connected by welds or rivets, with possible screw connections.

The main tasks of frames:

- transfer driving forces and braking forces to and from the transmission,

- secure the axles,

- carry body and load and transfer their weight to the axle (power function),

- enable the power plant function,

- ensure the safety of the vehicle crew (passive safety element).

Frame requirements:

- rigidity, strength and flexibility (especially with regard to bending and torsion), fatigue life,

- low weight,

- conflict-free with respect to vehicle components,

- long service life (corrosion resistance).

Separation of frames according to the principle of their design:

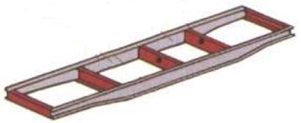

- ribbed frame: consists of two longitudinal beams connected by transverse beams, the longitudinal beams can be shaped to allow the axes to spring,

Rib frame

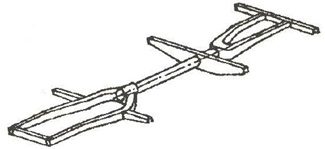

- diagonal frame: consists of two longitudinal beams connected by transverse beams, in the middle of the structure there is a pair of diagonals that increase the rigidity of the frame,

Diagonal frame

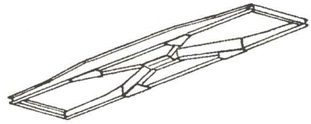

- Crossframe "X": consists of two side members that touch each other in the middle, the cross members protrude from the side members to the sides,

Cross frame

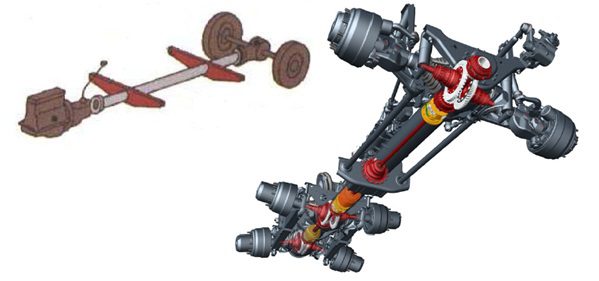

- rear frame: uses support tube and oscillating axles (pendulum axles), inventor Hans Ledwinka, technical director of Tatra; this frame was first used on a passenger car Tatra 11; it is characterized by considerable strength, especially torsional strength, therefore it is especially suitable for vehicles with intended off-road driving; does not allow flexible installation of the engine and transmission parts, which increases the noise caused by their vibrations,

Rear frame

- main frame frame: allows flexible installation of the engine and eliminates the disadvantage of the previous design,

Back frame

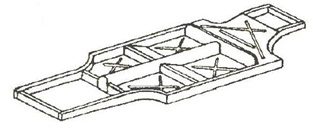

- platform frame: this type of structure is a transition between a self-supporting body and a frame

Platform frame

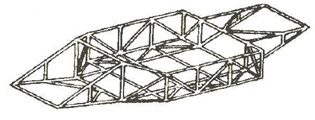

- lattice frame: This is a stamped sheet metal lattice structure found in more modern types of buses.

Lattice frame

- bus frames (space frame): consists of two rectangular frames located one above the other, connected by vertical partitions.

Bus frame

According to some, the term "road vehicle frame" also refers to the self-supporting body frame of a passenger car, which completely fulfills the function of the supporting frame. This is usually done by welding stampings and sheet metal profiles. The first production vehicles with self-supporting all-steel bodies were the Citroën Traction Avant (1934) and the Opel Olympia (1935).

The main requirements are the zones of safe deformation of the front and rear parts of the frame and the body as a whole. The programmed impact stiffness should absorb the impact energy as efficiently as possible, absorbing it due to its own deformation, thus delaying the deformation of the interior itself. On the contrary, it is as rigid as possible in order to protect passengers and facilitate their rescue after a traffic accident. Stiffness requirements also include side impact resistance. The longitudinal beams in the body have embossed notches or are bent so that after impact they are deformed in the right direction and in the right direction. The self-supporting body allows to reduce the total weight of the vehicle by up to 10%. However, depending on the current economic situation in this market sector, in practice, the repair of truck frames is rather carried out, the purchase price of which is significantly higher than that of passenger cars, and which customers are constantly using for commercial (transport) activities. ...

In the event of serious damage to passenger cars, their insurance companies classify it as total damage, and therefore usually do not resort to repairs. This situation has had a critical impact on sales of new passenger car equalizers, which have seen significant declines in recent years.

Motorcycle frames are typically welded for tubular profiles, with the front and rear forks being pivotally mounted on the frame thus manufactured. Pull repair accordingly. Replacing motorcycle frame parts is generally strongly discouraged by dealers and service centers of this type of equipment due to the potential potential safety risks for motorcyclists. In these cases, after diagnosing the frame and detecting a malfunction, it is recommended to replace the entire motorcycle frame with a new one.

However, different systems are used to diagnose and repair frames for trucks, cars and motorcycles, an overview of which is given below.

Diagnostics of vehicle frames

Damage assessment and measurement

In road traffic accidents, the frame and body parts are subjected to different types of loads (e.g. pressure, tension, bending, torsion, strut), respectively. their combinations.

Depending on the type of impact, the following deformations of the frame, floor frame or body may occur:

- Fall of the middle part of the frame (for example, in a head-on collision or collision with the rear of the car),

Failure of the middle part of the frame

- pushing the frame up (with a frontal impact),

Raise the frame up

- lateral displacement (side impact)

Lateral displacement

- twisting (for example, when a car is twisted)

Twisting

Additionally, cracks or cracks may appear on the frame material. With regard to the accurate assessment of damage, it is necessary to diagnose by visual inspection and, depending on the severity of the accident, it is also necessary to measure the car frame accordingly. his body.

Visual control

This includes determining the damage caused to determine if the vehicle needs to be measured and what repairs need to be done. Depending on the severity of the accident, the vehicle is inspected for damage from different points of view:

1. External damage.

When inspecting a car, the following factors should be checked:

- deformation damage,

- the size of joints (for example, in doors, bumpers, bonnet, luggage compartment, etc.) that may indicate deformation of the body and therefore measurements are necessary,

- slight deformations (for example, protrusions on large areas), which can be recognized by different reflections of light,

- damage to glass, paint, cracking, damage to the edges.

2. Damage to the floor frame.

If you notice any crushing, cracking, twisting, or out-of-symmetry when inspecting the vehicle, measure the vehicle.

3. Internal damage.

- cracks, squeezing (for this it is often necessary to dismantle the lining),

- lowering the seat belt pretensioner,

- deployment of airbags,

- fire damage,

- pollution.

3. Secondary damage

When diagnosing secondary damage, it is necessary to check whether there are other, other parts of the frame, acc. bodywork such as the engine, transmission, axle mounts, steering and other important parts of the vehicle chassis.

Determination of the order of repair

The damage determined during the visual inspection is recorded on the data sheet and the necessary repairs are then determined (eg replacement, part repair, part replacement, measurement, painting, etc.). The information is then processed by a computerized calculation program to determine the ratio of the cost of the repair to the time value of the vehicle. However, this method is mainly used in the repair of light vehicle frames, as the repair of truck frames is more difficult to assess from alignment.

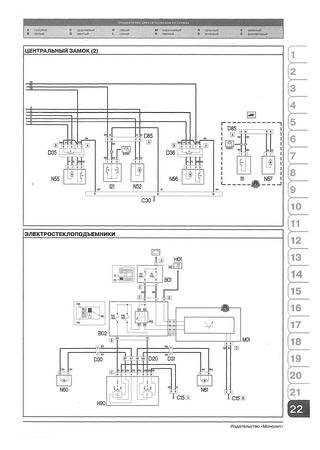

Frame / body diagnostics

It is necessary to determine if the deformation of the carrier has occurred, acc. floor frame. Measuring probes, centering devices (mechanical, optical or electronic) and measuring systems serve as a means of making measurements. The basic element is the dimension tables or measuring sheets of the manufacturer of the given vehicle type.

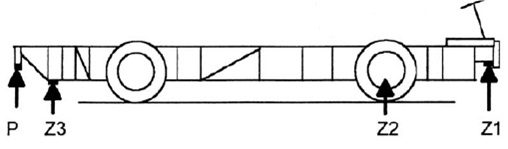

Truck diagnostics (frame measurement)

The truck geometry diagnostics system TruckCam, Celette and Blackhawk is widely used in practice to diagnose failures (displacements) of truck support frames.

1. TruckCam system (basic version).

The system is designed for measuring and adjusting the geometry of truck wheels. However, it is also possible to measure the rotation and tilt of the vehicle frame relative to the reference values specified by the vehicle manufacturer, as well as the total toe-in, wheel deflection and tilt and tilt of the steering axis. It consists of a camera with a transmitter (mounted with the ability to rotate on wheel disks using three-arm devices with repeatable centering), a computer station with a corresponding program, a transmitting radio unit and special self-centering reflective target holders that are attached to the car frame.

TruckCam Measuring System Components

Self-centering device view

When the infrared beam of the transmitter strikes a focused, reflective target located at the end of the self-centering holder, it is reflected back to the camera lens. As a result, the image of the aimed target is displayed on a black background. The image is analyzed by the microprocessor of the camera and sends the information to the computer, which completes the calculation based on the three angles alpha, beta, deflection angle and distance from the target.

Measurement procedure:

- self-centering reflective target holders attached to the vehicle frame (on the rear of the vehicle frame)

- the program detects the vehicle type and enters the vehicle frame values (front frame width, rear frame width, length of the self-centering reflector plate holder)

- with the help of a three-lever clamp with the possibility of repeated centering, the cameras are mounted on the wheel rims of the vehicle

- target data is read

- self-centering reflector holders move towards the middle of the vehicle frame

- target data is read

- self-centering reflector holders move towards the front of the vehicle frame

- target data is read

- the program generates a drawing showing the deviations of the frame from the reference values in millimeters (tolerance 5 mm)

The disadvantage of this system is that the basic version of the system does not continuously evaluate deviations from the reference values, and thus, during the repair, the worker does not know by which offset value in millimeters the frame dimensions have been adjusted. After the frame has been stretched, the sizing must be repeated. Thus, this particular system is considered by some to be more suitable for adjusting wheel geometry and less suitable for repairing truck frames.

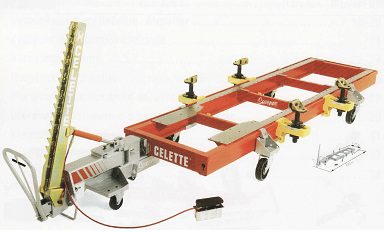

2. Celette system from Blackhawk

The Celette and Blackhawk systems operate on a principle very similar to the TruckCam system described above.

Celette's Bette system has a laser transmitter instead of a camera, and targets with millimeter scale indicating frame offset from reference are mounted on self-centering brackets instead of reflective targets. The advantage of using this measurement method when diagnosing frame deflection is that the worker can see during the repair to what value the dimensions have been adjusted.

In the Blackhawk system, a special laser sighting device measures the base position of the chassis in relation to the position of the rear wheels relative to the frame. If it doesn't match, you need to install it. You can determine the offset of the right and left wheels relative to the frame, which allows you to accurately determine the offset of the axle and the deflections of its wheels. If the deflections or deflections of the wheels change on a rigid axle, then some parts must be replaced. If the axle values and wheel positions are correct, these are the default values against which any frame deformation can be checked. It is of three types: deformation on the screw, displacement of the frame beams in the longitudinal direction and deflections of the frame in the horizontal or vertical plane. The target values obtained from the diagnostics are logged, where deviations from the correct values are noted. According to them, the compensation procedure and the design will be determined, with the help of which the deformations will be corrected. This repair preparation usually takes an entire day.

Blackhawk Target

Laser Beam Transmitters

Car diagnostics

XNUMXD frame / body size

With a XNUMXD frame / body measurement, only length, width and symmetry can be measured. Not suitable for measuring external body dimensions.

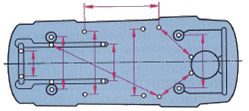

Floor frame with measurement control points for XNUMXD measurement

Point sensor

It can be used to define length, width, and diagonal dimensions. If, when measuring the diagonal from the right front axle suspension to the left rear axle, a dimensional deviation is found, this may indicate a skewed floor frame.

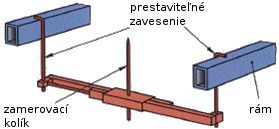

Centering agent

It usually consists of three measuring rods that are placed at specific measuring points on the floor frame. There are aiming pins on the measuring rods through which you can aim. Support frames and floor frames are suitable if the aiming pins cover the entire length of the structure when aiming.

Centering agent

Using a centering device

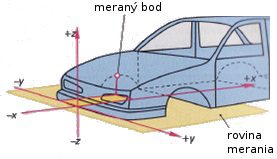

XNUMXD body measurement

Using three-dimensional measurements of body points, they can be determined (measured) in the longitudinal, transverse and vertical axes. Suitable for accurate body measurements

XNUMXD measurement principle

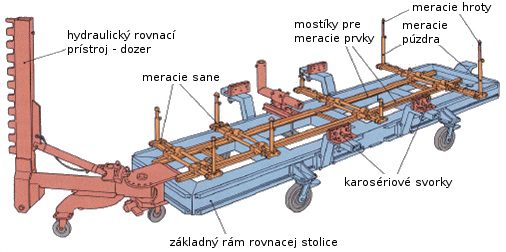

Straightening table with universal measuring system

In this case, the damaged vehicle is secured to the leveling table with body clamps. In the future, a measuring bridge is installed under the vehicle, while it is necessary to select three undamaged body measurement points, two of which are parallel to the longitudinal axis of the vehicle. The third measuring point should be located as far away as possible. The measuring carriage is placed on a measuring bridge, which can be precisely adjusted to the individual measuring points and the longitudinal and transverse dimensions can be determined. Each measuring gate is equipped with telescopic housings with a scale on which the measuring tips are installed. By extending the measuring tips, the slider moves to the measured points of the body so that the height dimension can be accurately determined.

Straightening table with mechanical measuring system

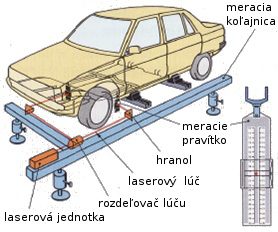

Optical measuring system

For optical body measurements using light beams, the measuring system must be located outside the base frame of the leveling table. The measurement can also be taken without the leveling stand support frame, if the vehicle is on a stand or if it is jacked up. For measurement, two measuring rods are used, located at right angles around the vehicle. They contain a laser unit, a beam splitter and several prismatic units. The laser unit creates a beam of rays that travel in parallel and become visible only when they collide with an obstacle. The beam splitter deflects the laser beam perpendicular to the short measuring rail and at the same time allows it to travel in a straight line. The prism blocks deflect the laser beam perpendicularly under the vehicle floor.

Optical measuring system

At least three undamaged measuring points on the housing must be hung with transparent plastic rulers and adjusted according to the measuring sheet in accordance with the corresponding connecting elements. After turning on the laser unit, the position of the measuring rails changes until the light beam hits the specified area of the measuring rulers, which can be recognized by the red dot on the measuring rulers. This ensures that the laser beam is parallel to the floor of the vehicle. To determine the additional height dimensions of the body, it is necessary to place additional measuring rulers at various measuring points on the underside of the vehicle. Thus, by moving the prismatic elements, it is possible to read the height dimensions on the measuring rulers and the length dimensions on the measuring rails. They are then compared to a measuring sheet.

Electronic measuring system

In this measuring system, suitable measuring points on the body are selected by a measuring arm that moves on a guide arm (or rod) and has a suitable measuring tip. The exact position of the measuring points is calculated by a computer in the measuring arm and the measured values are transmitted to the measuring computer by radio. One of the main manufacturers of this type of equipment is Celette, its three-dimensional measuring system is called NAJA 3.

Telemetry electronic measuring system controlled by Celette NAJA computer for vehicle inspection

Measurement procedure: The vehicle is placed on a lifting device and raised so that its wheels do not touch the ground. To determine the basic position of the vehicle, the probe first selects three undamaged points on the body, and then the probe is applied to the measurement points. The measured values are then compared with the values stored in the measuring computer. When evaluating the dimensional deviation, an error message or an automatic entry (record) in the measurement protocol follows. The system can also be used for repairing (towing) vehicles in order to constantly evaluate the position of a point in the x, y, z direction, as well as during reassembly of body frame parts.

Features of universal measuring systems:

- depending on the measuring system, there is a special measuring sheet with specific measuring points for each brand and type of vehicle,

- measuring tips are interchangeable, depending on the required shape,

- body points can be measured with the unit installed or disassembled,

- glued glass of cars (even cracked) must not be removed before measuring the body, as they absorb up to 30% of the twisting forces of the body,

- measuring systems cannot support the weight of the vehicle and cannot assess the forces during back deformation,

- in measuring systems using laser beams, avoid exposure to the laser beam,

- universal measuring systems operate as computer devices with their own diagnostic software.

Diagnostics of motorcycles

When checking the dimensions of the motorcycle frame in practice, the max system from Scheibner Messtechnik is used, which uses optical devices to evaluate in cooperation with a program for calculating the correct position of the individual points of the motorcycle frame.

Scheibner diagnostic equipment

Frame / body repair

Truck frame repair

Currently, in repair practice, BPL frame straightening systems from the French company Celette and Power cage from the American company Blackhawk are used. These systems are designed to equalize all types of deformations, while the construction of conductors does not require the complete removal of frames. The advantage is the mobile installation of towing towers for certain types of vehicles. Direct hydraulic motors with a push/pull force of more than 20 tons are used to adjust the frame dimensions (push/pull). In this way it is possible to align the frames with an offset of almost 1 meter. Car frame repair using heat on deformed parts is not recommended or prohibited depending on the manufacturer's instructions.

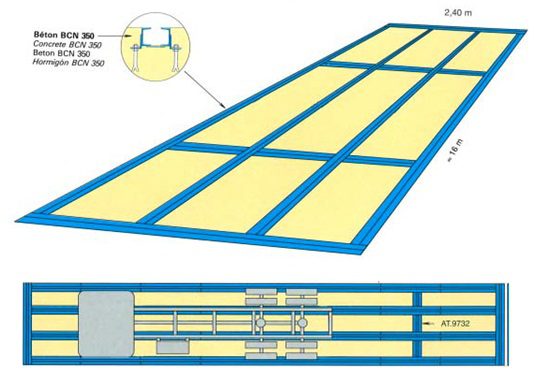

Straightening system BPL (Celette)

The basic element of the leveling system is a concrete steel structure, anchored by anchors.

View of the BPL leveling platform

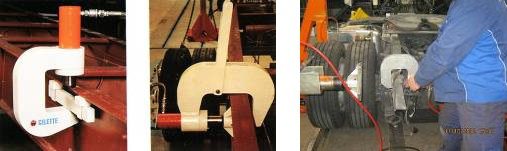

Massive steel rungs (towers) allow the frames to be pushed and pulled without heating, they are movably mounted on wheels that extend when the hand pull lever moves, raise the bar and can be moved. After releasing the lever, the wheels are inserted into the structure of the traverse (tower), and its entire surface rests on the floor, where it is attached to the concrete structure using clamping devices with steel wedges.

Traverse with an example of fastening to a foundation structure

However, it is not always possible to straighten the car frame without removing it. This happens depending on at what point it is necessary to support the frame, respectively. what point to push. When straightening the frame (example below) it is necessary to use a spacer bar that fits between the two frame beams.

Damage to the rear of the frame

Repair of the frame after disassembling parts

After leveling, as a result of the reverse deformation of the material, local overhangs of the frame profiles appear, which can be removed using a hydraulic jig.

Correcting local deformations of the frame

Editing cabins with Celette systems

If it is necessary to align the cabins of trucks, this operation can be performed using:

- the system described above using towing devices (traverses) from 3 to 4 meters without the need for disassembly,

Illustration of the use of a tall tower for leveling cabins

- using a special Celette Menyr 3 straightening bench with two four-meter towers (independent of the ground frame); towers can be removed and used for towing bus roofs also on the ground frame,

Special reclining chair for cabins

Strength cage straightening system (Blackhawk)

The device differs from the Celette leveling system, in particular, in the fact that the supporting frame consists of massive beams 18 meters long, on which the crashed vehicle will be built. The device is suitable for long vehicles, semi-trailers, harvesters, buses, cranes and other mechanisms.

The tensile and compressive force of 20 tons or more during balancing is provided by hydraulic pumps. The Blackhawk has several different push and pull attachments. The towers of the device can be moved in the longitudinal direction and hydraulic cylinders can be installed on them. Their pulling power is transmitted by powerful straightening chains. The repair process requires a lot of experience and knowledge of stresses and strains. Heat compensation is never used, as it can disturb the structure of the material. The manufacturer of this device expressly prohibits this. It takes about three days to repair deformed frames without disassembling individual parts of the car and parts on this device. In simpler cases, it can be terminated at a shorter time. If necessary, use pulley drives that increase the tensile or compressive strength to 40 tonnes. Any minor horizontal inequalities should be corrected in the same way as in the Celette BPL system.

Rovnation Blackhawk Station

At this editing station, you can also edit structural structures, for example, on buses.

Straightening the bus superstructure

Repair of truck frames with heated deformed parts - replacement of frame parts

In the conditions of authorized services, the use of heating deformed parts when aligning vehicle frames is used only to a very limited extent, based on the recommendations of vehicle manufacturers. If such heating occurs, then, in particular, induction heating is used. The advantage of this method over flame heating is that instead of heating the surface, it is possible to heat the damaged area pointwise. With this method, damage and dismantling of the electrical installation and plastic air wiring does not occur. However, there is a risk of alteration in the structure of the material, namely coarsening of the grain, especially due to improper heating in the event of a mechanical error.

Induction heating device Alesco 3000 (power 12 kW)

Replacement of frame parts is often carried out in the conditions of "garage" services, respectively. when repairing car frames, carried out on their own. This involves replacing deformed frame parts (cutting them out) and replacing them with frame parts taken from another undamaged vehicle. During this repair, care must be taken to install and weld the frame portion to the original frame.

Repair of passenger car frames

Body repairs following a car accident are based on individual attachment points for major vehicle parts (eg axles, engine, door hinges, etc.). The individual measurement planes are determined by the manufacturer, and the repair procedures are also specified in the vehicle repair manual. During the repair itself, various structural solutions are used for repair frames built into the floor of workshops or straightening stools.

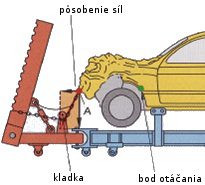

During a road accident, the body converts a lot of energy into frame deformation, respectively. body sheets. When leveling the body, sufficiently large tensile and compressive forces are required, which are applied by hydraulic traction and compression devices. The principle is that the deformation force of the back must be opposite to the direction of the deformation force.

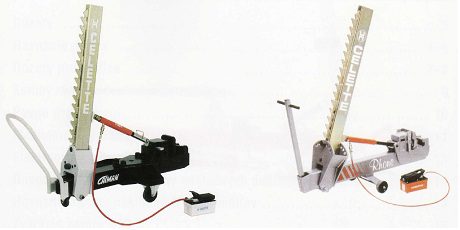

Hydraulic Leveling Tools

They consist of a press and a direct hydraulic motor connected by a high pressure hose. In the case of a high pressure cylinder, the piston rod extends under the action of high pressure; in the case of an extension cylinder, it retracts. The ends of the cylinder and piston rod must be supported during compression and expansion clamps must be used during expansion.

Hydraulic Leveling Tools

Hydraulic lift (bulldozer)

It consists of a horizontal beam and a column mounted at its end with the possibility of rotation, along which a pressure cylinder can move. The leveling device can be used independently of the leveling tables in case of small to medium damage to the body, which does not require very high tractive forces. The body must be secured at the points specified by the manufacturer with the chassis clamps and support pipes on the horizontal beam.

Hydraulic extensions (bulldozers) of various types;

Straightening table with hydraulic straightening device

The straightening chair consists of a sturdy frame that absorbs straightening forces. Cars are attached to it by the lower edge of the sill beam using clamps (clamps). The hydraulic leveling device can be easily installed anywhere on the leveling table.

Straightening table with hydraulic straightening device

Severe damage to the bodywork can also be repaired with leveling benches. Repairs performed in this manner are easier to carry out than using a hydraulic extension, since the reverse deformation of the body can take place in a direction directly opposite to the initial deformation of the body. In addition, you can use hydraulic levels based on the vector principle. This term can be understood as straightening devices that can stretch or compress a deformed body part in any spatial direction.

Changing the direction of the reverse deformation force

If, as a result of an accident, in addition to the horizontal deformation of the body, deformation also occurs along its vertical axis, the body must be retracted by a straightening device using a roller. The tensile force then acts in a direction directly opposite to the original deformation force.

Changing the direction of the reverse deformation force

Recommendations for body repair (straightening)

- body straightening must be carried out before the non-repairable body parts are separated,

- if straightening is possible, it is carried out cold,

- if cold drawing is impossible without the risk of cracks in the material, the deformed part can be heated over a large area using a suitable self-generating burner; however, the temperature of the material should not exceed 700 ° (dark red) due to structural changes,

- after each dressing it is necessary to check the position of the measuring points,

- in order to achieve accurate body measurements without tension, the structure must be stretched slightly more than the required size for elasticity,

- load-bearing parts that are cracked or broken must be replaced for safety reasons,

- pull chains must be secured with a cord.

Motorcycle frame repair

Figure: 3.31, View of the motorcycle dressing station

The article provides an overview of frame structures, diagnostics of damage, as well as modern methods of repairing frames and supporting structures of road vehicles. This gives owners of damaged vehicles the ability to reuse them without having to replace them with new ones, often resulting in significant financial savings. Thus, the repair of damaged frames and superstructures has not only economic but also environmental benefits.