Diagnostics, installation and ignition adjustment of injection and carburetor models VAZ 2107

Content

Sooner or later, the owner of the VAZ 2107 will be faced with the need to adjust the ignition system. This may be due to a violation of the ignition of the mixture in the cylinders, replacing the contact distributor with a non-contact one, etc. It is quite simple to adjust the ignition system of classic VAZ models.

Ignition adjustment VAZ 2107

Acceleration dynamics, fuel consumption, trouble-free engine starting and exhaust toxicity of carburetor VAZ 2107 directly depend on a properly installed ignition. If the ignition system (SZ) of newer injection models does not require special tuning, then cars with an old contact system require periodic adjustment.

When is ignition adjustment required?

Over time, the factory ignition settings get lost or no longer correspond to the operating conditions of the car. So, the need to adjust the SZ arises when using low-quality fuel or fuel with a different octane number. To assess the feasibility of this procedure, the ignition timing is determined. This is done in the following way.

- We accelerate the car up to 40 km/h.

- We sharply press the accelerator pedal and listen to the sound of the engine.

- If noise appears that disappears when the speed increases to 60 km / h, then there is no need to adjust the SZ.

- If the noise and detonation do not disappear with increasing speed, then the ignition is early and requires adjustment.

If the ignition timing is not set correctly, fuel consumption will increase and engine power will decrease. In addition, a number of other problems will arise - an incorrectly installed ignition will reduce the operational life of the power unit.

When a spark forms on the candle ahead of time, the expanding gases will begin to counteract the piston rising to the top position. In this case, we speak of early ignition. Due to too early ignition, the rising piston will expend more effort on compressing the resulting gases. This will lead to an increase in the load not only on the crank mechanism, but also on the cylinder-piston group. If a spark appears after the piston has passed the top dead center, then the energy generated from the ignition of the mixture enters the outlet without doing any useful work. In this situation, the ignition is said to be late.

Required Tools

To adjust the ignition of the VAZ 2107 you will need:

- key on 13;

- screwdriver;

- candle key;

- special key for the crankshaft;

- voltmeter or "control" (12V lamp).

High voltage wires

High voltage wires (HVP) transmit impulses from the coil to the spark plugs. Unlike other wires, they must not only withstand high voltage, but also protect other parts of the car from it. Each wire consists of a conductive wire with a metal ferrule, rubber caps on both sides and insulation. The serviceability and reliability of insulation is of great importance, since it:

- prevents moisture from entering the conductive element;

- reduces leakage current to a minimum.

Faulty high voltage wires

For GDP, the following main malfunctions are characteristic:

- breakage of the conductive element;

- voltage leakage due to poor-quality insulation;

- excessively high wire resistance;

- unreliable contact between GDP and spark plugs or its absence.

If the GDP is damaged, the electrical contact is lost and a discharge occurs, leading to voltage losses. In this case, it is not the nominal voltage that is supplied to the spark plug, but an electromagnetic pulse. Faulty wires lead to incorrect functioning of some sensors and to interruptions in the operation of the power unit. As a result, one of the cylinders ceases to perform useful work and runs idle. The power unit loses power and starts to detonate. In this case, they say that the engine "troit".

Diagnostics of high-voltage wires

If you suspect a malfunction of the GDP (engine "troit"), they must first be carefully examined - damage to the insulation, chips, touching the hot elements of the engine is possible. Particular attention should be paid to the wire contacts - they should not have traces of oxidation or soot. If no visible damage is found, they begin to detect a possible break and measure the GDP resistance with a multimeter. The wire resistance should be 3-10 kOhm. If it is zero, the wire is broken. It should also be borne in mind that the resistance should not deviate from the norm by more than 2-3 kOhm. Otherwise, the wire must be replaced.

Selection of high voltage wires

When buying new wires, you should pay attention to the recommendations of the automaker. On the VAZ 2107, wires of the VPPV-40 brand (blue) with a distributed resistance (2550 +/-200 Ohm / m) or PVVP-8 (red) with a distributed resistance (2000 +/-200 Ohm / m) are usually installed. An important indicator of GDP is the allowable stress. If the actual voltage values exceed the allowable values, a breakdown of the insulating layer of the cable may occur and the wire may fail. The voltage in the non-contact SZ reaches 20 kV, and the breakdown voltage is 50 kV.

The material from which GDP is made is also important. Typically, the wire has a polyethylene insulation in a PVC sheath. Silicone GDP are considered the most reliable. They do not become coarse in the cold, which prevents them from loosening in nests, and are less prone to breakouts. Among the manufacturers of wires, we can single out Champion, Tesla, Khors, etc.

Spark plug

Spark plugs are used to ignite the air-fuel mixture in the engine cylinders when high voltage is applied from the ignition coil. The main elements of any spark plug are a metal case, a ceramic insulator, electrodes and a contact rod.

Checking spark plugs VAZ 2107

There are many ways to test spark plugs. The most popular are the following algorithms.

- With the engine running, the high-voltage wires are removed in turn and listen to the operation of the engine. If no changes occur after disconnecting the wire, then the corresponding candle is faulty. This does not mean that it must be changed. In some cases, you can get away with cleaning it.

- The candle is unscrewed and a high-voltage wire is put on it. The candle body is leaned against the mass (for example, against the valve cover) and the starter is scrolled. If the part is working, the spark will be clear and bright.

- Sometimes candles are checked with a special tool - a gun. The candle is inserted into a special hole and checked for a spark. If there is no spark, the spark plug is bad.

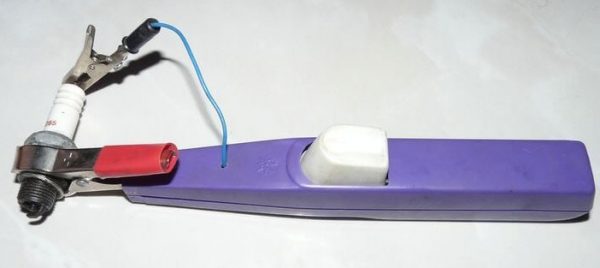

You can check the health of the spark plugs using a special tool - a gun

You can check the health of the spark plugs using a special tool - a gun - Candles can be checked with a homemade device from a piezo lighter. The wire from the piezoelectric module is extended and attached to the tip of the candle. The module is pressed against the body of the candle and the button is pressed. If there is no spark, the spark plug is replaced with a new one.

Video: checking spark plugs

The choice of spark plugs for VAZ 2107

Various models of spark plugs are installed on carburetor and injection engines VAZ 2107. In addition, the parameters of the candles depend on the type of ignition system.

Auto shops offer many types of spark plugs for the VAZ 2107, differing in technical characteristics, quality, manufacturer and price.

Table: characteristics of candles depending on the type of engine VAZ 2107

| For carburetor engines with contact ignition | For carbureted engines with contactless ignition | For injection 8-valve engines | For injection 16-valve engines | |

| Thread Type | M 14/1,25 | M 14/1,25 | M 14/1,25 | M 14/1,25 |

| Thread length, mm | 19 mm | 19 mm | 19 mm | 19 mm |

| Heat number | 17 | 17 | 17 | 17 |

| thermal case | Stands for spark plug insulator | Stands for spark plug insulator | Stands for spark plug insulator | Stands for spark plug insulator |

| The gap between the electrodes, mm | 0,5 - 0,7 mm | 0,7 - 0,8 mm | 0,9 - 1,0 mm | 0,9 - 1,1 mm |

Candles from various manufacturers can be installed on VAZ cars.

Table: spark plug manufacturers for VAZ 2107

| For carburetor engines with contact ignition | For carbureted engines with contactless ignition | For injection 8-valve engines | For injection 16-valve engines |

| A17DV (Russia) | A17DV-10 (Russia) | A17DVRM (Russia) | AU17DVRM (Russia) |

| A17DVM (Russia) | A17DVR (Russia) | AC DECO (USA) APP63 | AC DECO (USA) CFR2CLS |

| AUTOLITE (USA) 14–7D | AUTOLITE (USA) 64 | AUTOLITE (USA) 64 | AUTOLITE (USA) AP3923 |

| BERU (Germany) W7D | BERU (Germany) 14-7D, 14-7DU, 14R-7DU | BERU (Germany) 14R7DU | BERU (Germany) 14FR-7DU |

| BOSCH (Germany) W7D | BOSCH (Germany) W7D, WR7DC, WR7DP | BOSCH (Germany) WR7DC | BOSCH (Germany) WR7DCX, FR7DCU, FR7DPX |

| BRISK (Czech Republic) L15Y | BRISK (Italy) L15Y, L15YC, LR15Y | CHAMPION (England) RN9YC | CHAMPION (England) RC9YC |

| CHAMPION (England) N10Y | CHAMPION (England) N10Y, N9Y, N9YC, RN9Y | DENSO (Japan) W20EPR | DENSO (Japan) Q20PR-U11 |

| DENSO (Japan) W20EP | DENSO (Japan) W20EP, W20EPU, W20EXR | EYQUEM (France) RC52LS | EYQUEM (France) RFC52LS |

| NGK (Japan/France) BP6E | EYQUEM (France) 707LS, C52LS | MARELLI (Italy) F7LPR | MARELLI (ITALY) 7LPR |

| HOLA (Netherlands) S12 | NGK (Japan/France) BP6E, BP6ES, BPR6E | NGK (Japan/France) BPR6ES | NGK (Japan/France) BPR6ES |

| MARELLI (Italy) FL7LP | MARELLI (Italy) FL7LP, F7LC, FL7LPR | FINVAL (Germany) F510 | FINVAL (Germany) F516 |

| FINVAL (Germany) F501 | FINVAL (Germany) F508 | HOLA (Netherlands) S14 | HOLA (Netherlands) 536 |

| WEEN (Netherlands/Japan) 121–1371 | HOLA (Netherlands) S13 | WEEN (Netherlands/Japan) 121–1370 | WEEN (Netherlands/Japan) 121–1372 |

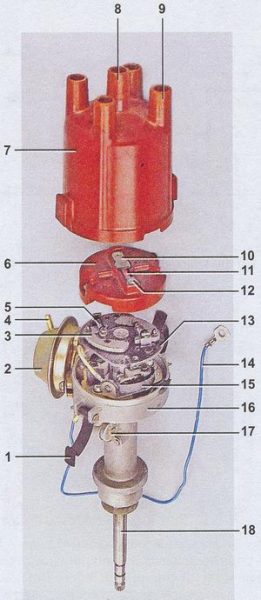

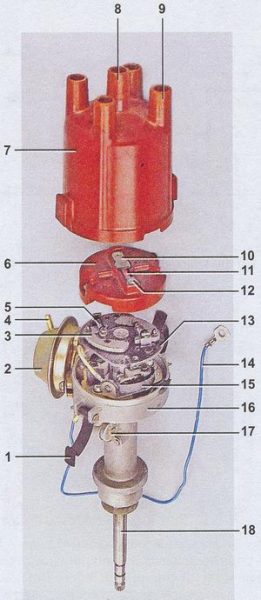

Contact distributor VAZ 2107

The distributor in the ignition system performs the following functions:

- starts the process of spark formation;

- transmits high voltage from the coil to the spark plugs;

- controls and regulates the moment of spark formation depending on the fuel and driving mode.

The distributor rotates with a crankshaft through a number of additional elements. During operation, it wears out and requires periodic inspection and maintenance. Particular attention should be paid to his contacts.

Checking the distributor

The reasons for checking the distributor are:

- unstable idle;

- problems with starting the engine;

- engine stalling while driving.

A distributor failure is identified as follows:

- The presence of a spark is checked on the unscrewed spark plugs.

- If there is no spark on the candles, the GDP is checked.

- If the spark still does not appear, the distributor is faulty.

Checking the distributor itself begins with an inspection of the slider, contacts and cover. With a high mileage, as a rule, the contacts burn out and need to be cleaned. Contaminants are removed from the internal surface of the structure. In garage conditions, checking the performance of the distributor is quite simple. To do this, you will need the simplest fixtures or devices that are used to adjust the ignition (for example, a regular light bulb).

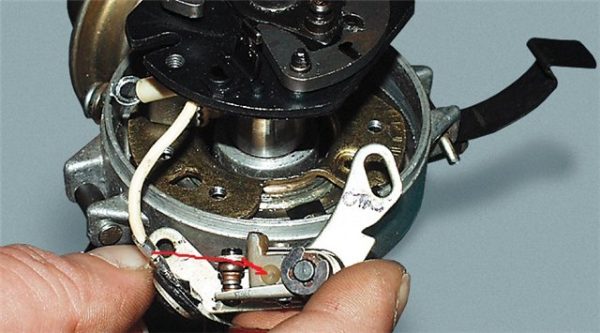

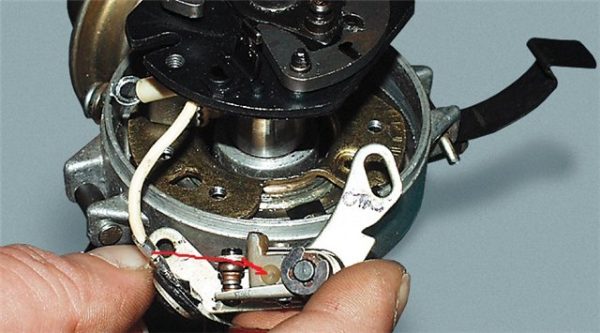

Contact gap adjustment

Before starting the adjustment, it is necessary to remove the cover of the distributor. For VAZ 2107, the angle of the closed state of the contacts should be 55 ± 3˚. This angle can be measured with a tester or feeler gauge from the gap between the contacts in the open state. For the convenience of adjusting the gap, it is recommended to remove the distributor from the car, but after that you will have to re-set the ignition. However, this can be done without dismantling.

To check the clearance, the crankshaft is rotated to the position at which this clearance will be maximum. Measured with a flat feeler gauge, the gap should be 0,35–0,45 mm. If its actual value does not fall within this interval, an adjustment is required, performed as follows.

- Using a screwdriver, loosen the fasteners of the contact group and the screw for adjustment.

To adjust the gap between the contacts, loosen the fastening of the contact group and the adjusting screw

To adjust the gap between the contacts, loosen the fastening of the contact group and the adjusting screw - By moving the plate of the contact group, we set the required gap and tighten the fasteners.

The gap between the contacts, set using a flat probe, should be 0,35–0,45 mm

The gap between the contacts, set using a flat probe, should be 0,35–0,45 mm - We check the correctness of the gap setting, clamp the adjusting screw of the contact group and install the distributor cover in place.

After adjusting and checking the clearance, tighten the adjusting screw

After adjusting and checking the clearance, tighten the adjusting screw

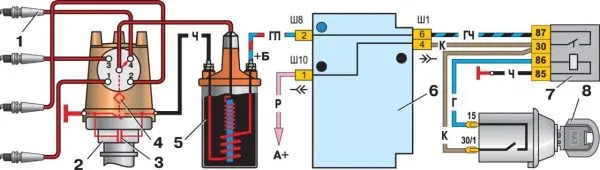

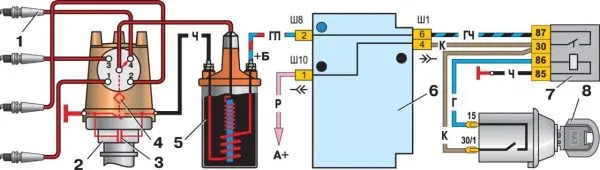

Contactless distributor VAZ 2107

Contactless and electronic ignition are one and the same. However, some argue that the systems are different. The fact is that different devices are used in the ignition systems of carburetor and injection engines. Perhaps this is where the confusion comes from. Corresponding to its name, a contactless distributor does not have mechanical contacts, the functions of which are performed by a special device - a switch.

The main advantages of a non-contact distributor over a contact one are as follows:

- there is no need for periodic maintenance of contacts;

- due to the absence of a contact group that is subject to wear, reliability increases;

- the spark is distributed over the cylinders more evenly and does not depend on the engine operating mode;

- due to the absence of vibration and mechanical influences on the contacts, the service life of the distributor increases;

- fuel consumption decreases, engine power increases, the content of harmful substances in the exhaust decreases;

- the engine starts more easily at low temperatures, since the voltage on the candles remains stable at low speeds and a weakly charged battery.

Checking the contactless distributor

If there are problems in the contactless ignition system, then first the candles are checked for the presence of a spark, then the GDP and the coil. After that, they move on to the distributor. The main element of a contactless distributor that can fail is the Hall sensor. If a sensor malfunction is suspected, it is either immediately changed to a new one, or checked with a multimeter set to voltmeter mode.

Diagnostics of the Hall sensor performance is carried out as follows:

- With pins, they pierce the insulation of the black-and-white and green wires going to the sensor. A multimeter set in voltmeter mode is connected to the pins.

- Turn on the ignition and, slowly rotating the crankshaft, look at the readings of the voltmeter.

- With a working sensor, the device should show from 0,4 V to the maximum value of the on-board network. If the voltage is lower, the sensor is faulty and needs to be replaced.

Video: Hall sensor test

In addition to the Hall sensor, a malfunction of the vacuum corrector can lead to failure of the distributor. The performance of this node is checked as follows.

- Remove the silicone tube from the carburetor and start the engine.

- We create a vacuum by taking a silicone tube into your mouth and drawing in air.

- We listen to the engine. If the speed increases, the vacuum corrector is working. Otherwise, it is replaced with a new one.

Diagnostics of the centrifugal ignition timing may also be required. This will require disassembly of the distributor. Particular attention should be paid to the condition of the springs - you need to evaluate how the weights of the regulator diverge and converge.

In addition, it is necessary to check the cover of the distributor. To do this, it is removed and inspected for burnout, cracks, and the condition of the contacts is assessed. If there is visible damage or signs of wear on the contacts, a new cover is installed. Then inspect the runner. If traces of strong oxidation or destruction are found, it changes to a new one. And finally, with a multimeter set to ohmmeter mode, check the resistance of the resistor, which should be 1 kOhm.

Video: checking the cover of the distributor VAZ 2107

Knock sensor

The knock sensor (DD) is designed to save fuel and increase engine power. It consists of a piezoelectric element that generates electricity when detonation occurs, thereby regulating its level. With an increase in the frequency of oscillations, the voltage supplied to the electronic control unit increases. DD adjusts the ignition settings to optimize the ignition process in the cylinders of the air-fuel mixture.

Knock sensor location

On VAZ DD cars, it is located on the power unit block between the second and third cylinders. It is installed only on engines with a contactless ignition system and a control unit. On VAZ models with contact ignition, there is no DD.

Knock Sensor Malfunction Symptoms

A malfunction of the knock sensor is manifested as follows.

- Acceleration dynamics are deteriorating.

- The engine "troit" at idle.

- During acceleration and at the beginning of the movement, the CHECK indicator lights up on the instrument panel.

If any of these symptoms appear, a DD check will be required.

Knock sensor check

DD is checked with a multimeter. First you need to check the compliance of the value of its resistance with the values \uXNUMXb\uXNUMXbregulated by the manufacturer. If the values differ, replace DD. The check can also be done in another way. For this:

- The multimeter is set to the voltmeter mode in the "mV" range and the probes are connected to the sensor contacts.

- They hit the body of the DD with a solid object and look at the readings of the device, which, depending on the strength of the impact, should vary from 20 to 40 mV.

- If DD does not respond to such actions, it is changed to a new one.

Video: checking the knock sensor

Watch this video on YouTube

Setting the ignition timing

The ignition system is a very sensitive unit that requires careful tuning. This is the only way to achieve optimal engine performance, minimum fuel consumption and maximum possible power.

Ignition Angle Setting Methods

There are several ways to adjust the ignition timing.

- Aurally.

- With a light bulb.

- By strobe.

- By sparks.

The choice of method depends primarily on the availability of the necessary devices and improvised means.

Adjusting the ignition by ear

This method is notable for its simplicity, but it is recommended only for experienced motorists to resort to it. The work is performed on a warm and running engine in the following sequence.

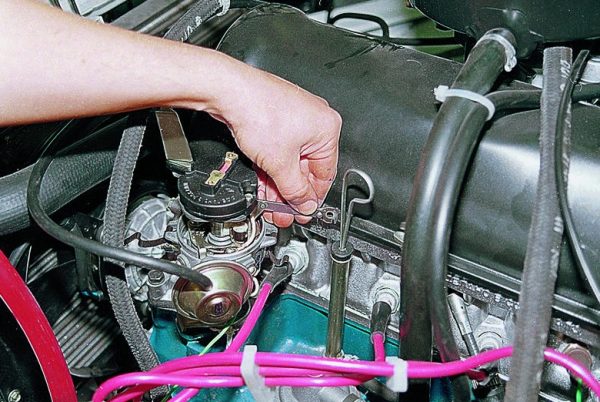

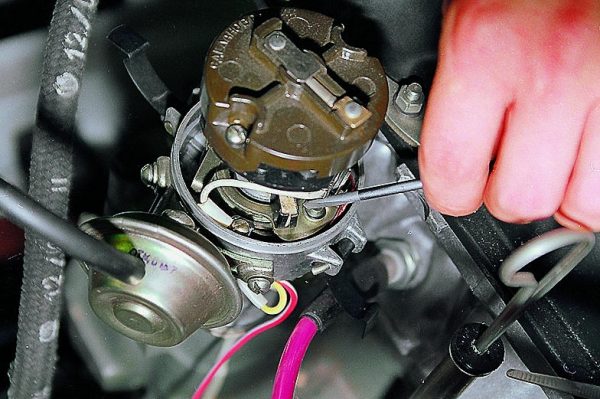

- Loosen the distributor nut and begin to rotate it slowly.

Before adjusting the ignition, it is necessary to loosen the distributor mounting nut

Before adjusting the ignition, it is necessary to loosen the distributor mounting nut - Find the position of the distributor at which the engine speed will be maximum. If the position is found correctly, then when you press the accelerator pedal, the engine will quickly and smoothly gain momentum.

In the process of adjustment, they find such a position of the distributor, in which the engine will run at maximum speed

In the process of adjustment, they find such a position of the distributor, in which the engine will run at maximum speed - Stop the engine, turn the distributor 2˚ clockwise and tighten the fastening nut.

Adjusting the ignition with a light bulb

You can adjust the ignition of the VAZ 2107 using a 12V bulb (car "control"). This is done in the following way.

- The first cylinder is set to a position in which the mark on the crankshaft pulley will coincide with the mark 5˚ on the cylinder block. To turn the crankshaft, you will need a special key.

To turn the crankshaft pulley when setting marks, you will need a special key

To turn the crankshaft pulley when setting marks, you will need a special key - One of the wires coming from the light bulb is connected to ground, the second - to the contact of the "K" coil (low voltage circuit).

- Loosen the distributor mount and turn on the ignition.

- By rotating the distributor, they are looking for the position at which the light will light up.

- Tighten the distributor mount.

Video: ignition adjustment with a light bulb

Watch this video on YouTube

Ignition adjustment with a stroboscope

Connecting the stroboscope and the process of setting the ignition timing is carried out in the following order:

- The engine is warmed up to operating temperature.

- The tube is removed from the vacuum corrector, and a plug is installed in the hole formed.

- The power wires of the stroboscope are connected to the battery (red - to plus, black - to minus).

The most accurate ignition timing is set using a stroboscope

The most accurate ignition timing is set using a stroboscope - The remaining wire (sensor) of the device is fixed on a high-voltage wire going to the first candle.

- The stroboscope is installed in such a way that its beam falls on the crankshaft pulley parallel to the mark on the timing cover.

- Start the engine and loosen the distributor mount.

- By rotating the distributor, they ensure that the beam skips exactly at the moment it passes the mark on the crankshaft pulley.

Video: ignition adjustment using a stroboscope

Watch this video on YouTube

The order of operation of the engine cylinders VAZ 2107

The VAZ 2107 is equipped with a gasoline, four-stroke, four-cylinder, in-line engine, with an overhead camshaft. In some cases, for diagnostics and troubleshooting, it is necessary to know the sequence of operation of the cylinders of the power unit. For the VAZ 2107, this sequence is as follows: 1 - 3 - 4 - 2. The numbers correspond to the cylinder numbers, and the numbering starts from the crankshaft pulley.

Setting the slider direction

With a properly adjusted ignition, the elements of the engine and the ignition system must be set in accordance with certain rules.

- The mark on the crankshaft pulley must be opposite the 5˚ mark on the cylinder block.

The mark on the crankshaft pulley and the middle mark on the cylinder block (5˚) must match

The mark on the crankshaft pulley and the middle mark on the cylinder block (5˚) must match - The distributor slider should be directed to the contact of the distributor cap corresponding to the first cylinder.

Thus, adjusting the ignition timing of the VAZ 2107 is quite simple. Even an inexperienced motorist who has a minimum set of tools and carefully follows the instructions of specialists can do this. At the same time, one should not forget about safety requirements, since most of the work is associated with high voltage.