Diesel engines - a unique alternative to gasoline engines

Content

- Diesel engine development over the years

- Design of modern diesel engines

- How do diesel engines work?

- Reliable and economical 1.9 TDI engine.

- Advantages and Disadvantages of Diesel Engines

- Diesels fail?

- The most common diesel engine failures are the exhaust gas treatment system

- Choice between diesel and petrol engine

- Reliable and low-maintenance TDI engines

Rudolf Alexander Diesel is credited as the creator of the diesel drive, which was the forerunner of engines such as the 2.0 TDI, 1.9 TDI, 1.6 TDI and 1.6 HDI. Worked on self-igniting drives. He wanted his work to be much more efficient than the petrol solutions known so far. Initially, diesel was not used in passenger cars, but in marine ships and train locomotives. The first full-fledged design of this class, used in wheeled vehicles, is the one that was installed on the Mercedes-Benz 260 D.

Diesel engine development over the years

The start of production in 1936 led to the dynamic development of the diesel engine.. Just two years later, the number of produced Mercedes with this power unit amounted to 2000 units. The 50s were the heyday of new technologies as an alternative to gasoline solutions. The advantages of these engine designs were considered to be their high survivability and low fuel consumption, especially at long distances. 1978 - the date of production of the first car equipped with an engine with an additional turbine, i.e. turbodiesel. It was a French Peugeot 604.

The 1985 Fiat Croma and 1997 Alfa Romeo JTD are considered to be the forerunners of modern diesel cars, equipped with a common rail injection system. Currently, these solutions are being replaced by hybrid and electric models. One of the reasons is environmental measures aimed at completely ridding the automotive industry of emissions of harmful volatile compounds into the atmosphere. However, if you're thinking about buying a diesel-powered car, be aware that the latest cars are equipped with very green, low-emission solutions.

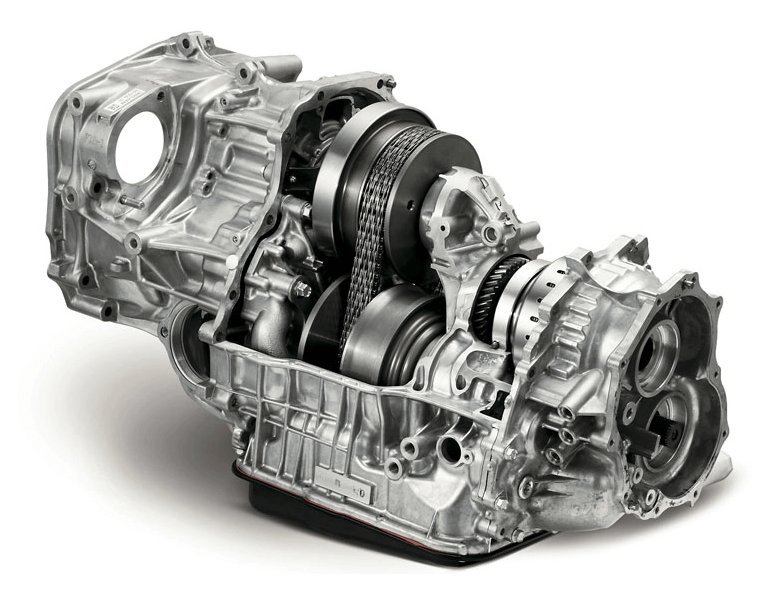

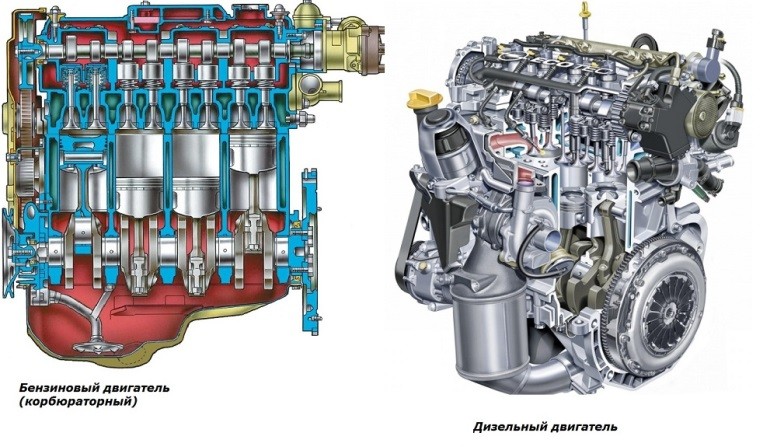

Design of modern diesel engines

What is the design of modern diesel engines? This is not much different from what we may have known from the automotive industry in previous decades. The diesel engine consists of camshafts and crankshafts, a flywheel, a special reverse-lowering mechanism, as well as pushers and a connecting rod. It also houses the pre-combustion chamber, injectors, air filter and cylinder head system. The elements are supported by a team of innovative electronic controllers.

How do diesel engines work?

In operation, the 2.0 HDI engine, like other diesel engines, burns a fuel-air mixture. Unlike gasoline solutions, it does not require a spark to ignite because it happens automatically. Compressed air is sucked into the cylinder from the outside and heated to a very high temperature in the range of 700-900oC. As a result, the mixture ignites and oil is injected. This principle of operation is associated with cold start problems in autumn and winter.

Reliable and economical 1.9 TDI engine.

Undoubtedly, one of the most reliable powertrains is the durable and low maintenance 1.9 TDI diesel engine. A diesel of this class is often cited by experienced mechanics as a model of reliability. Surely you could meet him when you were looking for a car. The iconic design features Turbo Direct Injection. Initially, a rotary injection pump with a set of two-stage nozzles was used here.

The technology solution developed by Volkswagen engineers has revolutionized the automotive industry and allowed for an efficient and economical engine design. A relatively small amount of fuel allows you to provide a lot of power here. At the same time, the 1.9 TDI engine we are describing is a Diesel, easy to maintain and practically maintenance-free. One of the first cars to which it was installed was the legendary Audi 80. In subsequent years, it was also installed on Seat, Skoda and Ford cars.

What are the disadvantages of the 1.9 TDI engine?

If you are wondering if the popular diesel engine is flawless, then know that it too is at risk of failure. One of the most commonly reported failures of the 1.9 TDI engine is damage to the injection system. It is manifested by a noticeable decrease in power, and at the same time an increase in fuel consumption, as well as black, thick smoke coming from the exhaust pipe. Another problem is the EGR valve and the associated oil leakage, and at the same time a practical lack of dynamics, which is determined by problems with the turbocharger.

Many drivers complain about the high cost of repairing the 1.9 TDI engine. For example, replacing a turbine with a set of injectors and a dual-mass flywheel costs even several thousand zł. An alternative in this case may be the service of complex regeneration of the system. Remember, however, that often the mentioned breakdowns are usually not caused by a factory defect, but by improper operation and maintenance of the car by inexperienced mechanics. For this reason, it is worth checking the technical condition of the drive regularly.

Advantages and Disadvantages of Diesel Engines

One of the biggest advantages of diesel engines is low fuel consumption on long journeys. They are unmatched when compared to petrol or LPG engines. It should also be noted the high torque and excellent dynamics, already achieved at about 2000 rpm. This makes it easier to drive, overtake and get unbridled driving pleasure. It is also not uncommon to increase productivity through software modifications at the level of the electronic control system.

The main disadvantage of diesel units of the 2.0 HDI engine type is the high purchase cost compared to technological solutions running on gasoline. This also results in higher repair and maintenance costs. The work culture is also not up to the mark. You can definitely feel the difference in the louder operation of the drive system. The design of a diesel engine is also more complex. The most vulnerable elements are:

- turbocharger;

- particulate filter DPF;

- EGR valves and common rail injectors.

Diesels fail?

Serious breakdowns and costly repairs of diesel engines are among the most common arguments against diesel solutions. Their complex structure makes them vulnerable to many faults that require the intervention of an experienced mechanic. Often their cause is urban operation, which is associated with driving on an underheated drive unit. Remember that in the city and on short trips, especially in autumn and winter, a car with a gasoline engine will be a much better choice.

The most common diesel engine failures are the exhaust gas treatment system

Among the most frequently cited faults in diesel engines are defects in advanced exhaust gas cleaning systems. Their task is to reduce the emission of nitrogen oxides and other harmful substances into the atmosphere. SCR systems or DPF filters effectively reduce the amount of unwanted volatile compounds coming out of the exhaust gases. At the same time, they wear out after several tens or several hundred thousand kilometers, depending on the mode of operation of the car. A clogged component can be replaced, cleaned or repaired by a professional service.

Failure of a turbocharger in a diesel engine

Another element subject to frequent failures in diesel engines is the turbocharger and its accessories. Dynamic, sporty driving in the city immediately after starting a diesel engine has a bad effect on the operation and condition of the turbine. The consequence is defects in the intake system, which are associated with costly repairs or regeneration. The cost of repairs can vary from a few to several thousand zlotys. In the case of many older cars, this is unprofitable. Therefore, you should take care of the correct operation of the power unit, and choose another car for street racing.

Defects in the injection system in diesel engines

The injection system is another knot that you may encounter if you have a diesel car. There are many factors that contribute to injector failure. This may be low-quality fuel, maintenance by an inexperienced mechanic, as well as the use of rash chip tuning. Tips can also be clogged with impurities in the form of metal filings. There is also a burnout of the ignition coils and leaks from under the seals. The cost of repairs usually ranges from a few hundred to several thousand zlotys.

Swirl flaps and EGR

Another item worth mentioning is swirl flaps and EGR. Their task is to ensure a sufficiently low emission of harmful volatile compounds and, therefore, comply with environmental standards.

Flywheel in 1.6 HDI and 1.9 TDI

The last component found in many units like the 1.6 HDI or 1.9 TDI is the Dual Mass Flywheel. This is a problem for owners of cars older than a decade with a diesel engine. The reason for its failure is usually frequent driving at low speeds. The cost of repairs can exceed 1000 euros

Choice between diesel and petrol engine

The choice between diesel and gasoline is an eternal dilemma for owners of cars, vans and trucks. If you are also wondering which design would be best for you, we will try to give you some advice.

- First of all, you need to consider how many kilometers you will cover in a year. If you'll be driving mostly on the road, a diesel engine like the 1.6 HDI or 1.9 TDI is a great choice.

- However, if you plan to travel mainly in the city for short distances, then a car with a gasoline engine will be the best purchase.

- Low fuel consumption, especially on long journeys, is another advantage that encourages users to opt for diesel vehicles. The advantages are especially evident when considering designs with a power of several hundred hp. The consumption of diesel fuel is then significantly lower compared to a car with similar characteristics, but with a gasoline engine.

- If you care about the environment, you should definitely choose one of the newer models, which additionally have diesel particulate filters installed. They comply with environmental standards and help reduce emissions of volatile substances into the atmosphere.

What else should I look for when buying a diesel car?

When considering buying a car with a diesel engine, it is worth paying attention not only to the costs of daily operation, but also to periodic maintenance and possible repairs. They are much higher than in the case of gasoline engines. However, they often arise as a result of improper maintenance by inexperienced mechanics, and at the same time the negligence of the users themselves. For this reason, such a car should only be repaired by trusted specialists with relevant experience. In this way, you will avoid costly replacement of the dual mass flywheel, DPF filter or EGR valves.

Reliable and low-maintenance TDI engines

There is no doubt that TDI and HDI engines are durable and cheap to run. Diesel units are characterized by low fuel consumption, especially when driving economically on long domestic and international routes. At the same time, they are less problematic than petrol vehicles with an additional LPG installation. They are the ideal choice as fleet and company vehicles. They are also often chosen by construction companies.

Due to the complexity of modern diesel engines, they can be more expensive to maintain than gasoline engines. This fact should be taken into account when considering the purchase of a new or used car. Especially in the latter case and on vehicles with high mileage, an overhaul of the cylinder block may be required. Before completing the transaction, you should go to the nearest diagnostic station and check the technical condition of the car you are interested in.