Diesel swirl dampers. Trouble that can destroy the engine

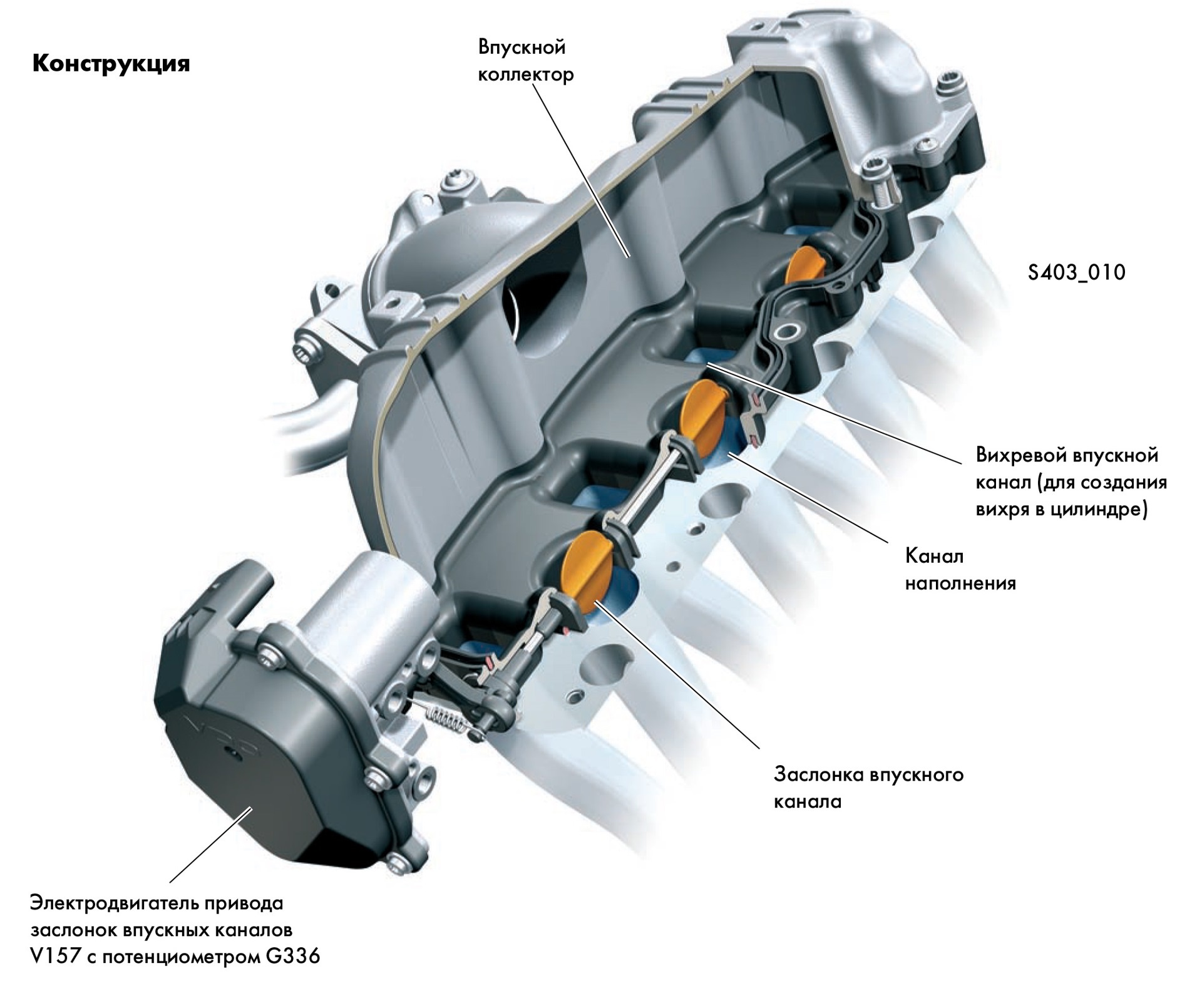

Swirl flaps are a solution used in many common rail diesel engines. The air turbulence it creates in the intake system just ahead of the intake valves helps the combustion process at low revs. As a result, exhaust gases should be cleaner, with a lower content of nitrogen oxides.

So much theory, which most likely corresponds to reality, if only everything in the engine was completely serviceable and clean. As a rule, the valves mounted on the axis change their installation angle depending on the engine speed - at low they are closed so that less air enters the cylinders, but they are twisted accordingly, and at high they must be open. so that the engine "breathes" fully. Unfortunately, this device operates under very adverse conditions and is therefore prone to failure. Usually they consist in blocking the valves due to accumulated soot or even separating them from the fasteners.

Common symptom of flap failure stuck in the open position, the “bottom” of the engine is very weak, i.e. until the turbocharger reaches a noticeably high boost pressure. As a result increased levels of soot in exhaust gasesAnd when they return to the intake through the EGR valve, more pollutants accumulate in the intake system. Therefore, the collector - already dirty - becomes dirty even faster.

When the throttles are stuck closed, you may experience a drop in power at higher RPMs as too little air is being drawn into the cylinders. Then the level of soot in the system also increases. Unfortunately, an increase in exhaust smoke, regardless of speed, has its further consequences in the form of an accelerated exhaust system wear (DPF filter) and turbocharger.

As a rule, such symptoms appear after a run of about 100–2005 km. km, although engine manufacturers eventually recognized the problem and improved many designs after '90. a problem that became significantly worse when the first common rail damper diesel engines of the late 47s began to fail badly. This is a situation that often arose when the flaps, due to poor mounting in the manifold, broke off and fell deeper into the intake system, colliding with the intake valve, and even after breaking they ended up in the cylinder. There he was often seriously damaged. The engines that were particularly vulnerable to this phenomenon were the M57 and M1.9 from BMW and the 2.4 and 1.9 JTD from Fiat and the CDTi twin from Opel.

Experts recommend - remove the flaps!

Although this seems debatable due to the purity of the exhaust gases, mechanics who deal with diesel engines on a daily basis almost unanimously recommend removing the flaps. It consists in using plugs at their place of installation and / or disabling their operation in the motor controller. Specialists in popular diesels assure that the absence of swirl flaps does not affect the operation and characteristics of the engine. This is interesting because locking the flaps in the open position affects the lower rpm range, so their very presence in these conditions seems necessary. Therefore, in some engines, along with the removal of the flaps, it is recommended to reprogram the maps in the controller.

Moreover, diesels with high mileage even have an improvement in the quality of exhaust gases (less smoke) after removing the dampers. This is one of several solutions used in modern diesel engines that affect exhaust gas quality, but only up to a certain point (low mileage). Over time, engines without sustainable solutions just run better and perform better.

Or maybe replace?

About a decade ago, this was an expensive repair because intake manifolds were only offered as factory parts at around PLN 2000 each. On V6 engines, sometimes two need to be replaced. Today, some companies offer collector regeneration or replacement for a few hundred zł, and even damper replacements (so-called regeneration kits) have appeared on the market. Their prices are small, about 100-300 zł per set.

This situation makes the repair of dampers (their regeneration or replacement of the entire collector) no longer excessively expensive, and therefore quite justified. However, there is no evidence that installing new, functioning dampers on an engine with high mileage, and therefore typically already internally polluted, will improve the combustion process and thus the cleanliness of the exhaust gases. Nevertheless, having a complete factory engine is worth it if only for this reason. As intended by its designer.