Why do we need oil seals in the engine and how they differ from the cuff

Content

In the general case, both the stuffing box and the cuff serve to seal closed cavities when a shaft or a stem that is in motion has to be removed from them.

The crankcase (cavity) can be filled with oil, grease or other gaseous, vapor or liquid medium, and outside there is either another zone of the unit, or an external environment, often polluted and humid.

There is also a pressure drop that reaches a significant and unpredictable value.

The most incredible example of complexity is the submarine stern tube sealing the propeller shaft and operating under enormous pressure at great depths.

What is the difference between an omentum and a cuff

There are two generalized options for the output of a shaft or rod - when the part reciprocates, or rotational. There are also typical applications - pistons and rods of hydraulic mechanisms, as well as shafts of engines and transmission units in cars.

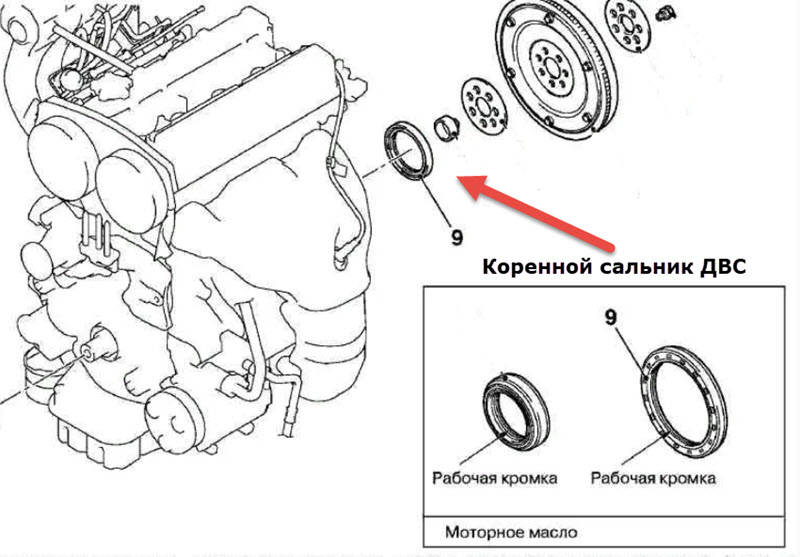

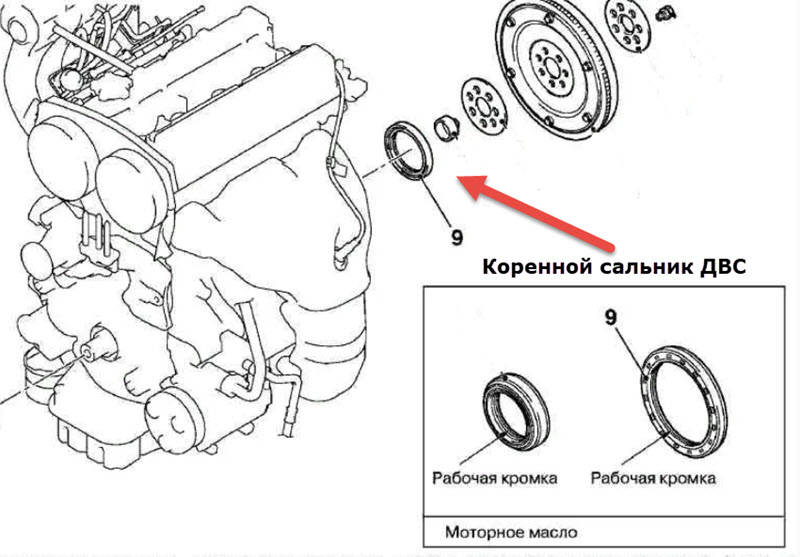

If we consider the rear oil seal of the crankshaft of an automobile motor, then its main task is to prevent the passage of engine oil into the cavity of the gearbox housing. There may be a mechanical gearbox clutch that does not tolerate the appearance of even a small amount of oil, or a torque converter cavity that is not critical to leaks, but oil consumption is still unacceptable.

Cuffs work a little differently. When sealing hydraulic rods, leakage can only be prevented if the elastic material of the collar is subjected to the pressure of the working fluid. The higher it is, the tighter the cuff is clamped, withstanding high pressures. The cuff does not need reinforcement.

The gland, on the contrary, is a more complex structure. It should not deform, and self-compression causes additional wear. In reality, it exists, but within small limits.

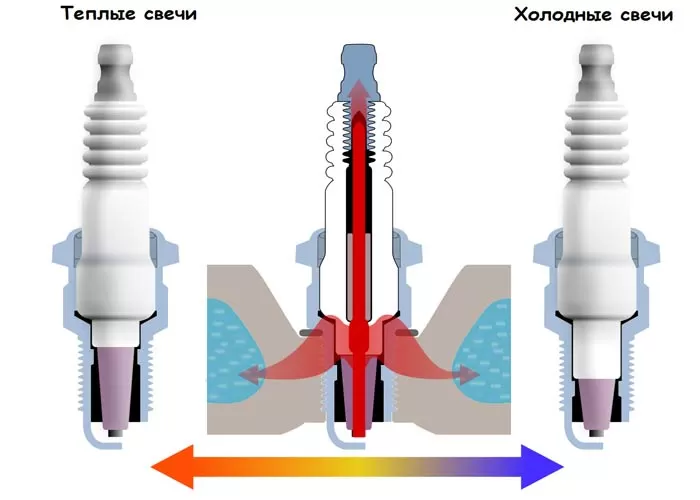

With significant pressure, the stuffing box is greatly complicated. This does not apply to the crankshaft, the pressure there is small, but it also works on self-compression. The main clamp of the working edge is carried out by an annular twisted spring.

You can reduce the basic differences between the cuff and the gland, the latter may contain:

- reinforcement of the material between the outer surface and the annular working edge;

- the presence of several edges, including external dustproof ones;

- the working area is sealed with a steel spring;

- materials are very diverse, from plastics to varieties of natural and synthetic rubber;

- type-setting (cassette) design, when the edge and the surface on which it works are part of the stuffing box.

The cuffs are simpler in design, but their cross-sectional shape is selected very carefully, as is the elastic material.

Applications

In cars, oil seals serve not only to seal the crankcases of motors:

- in gearboxes, input, output shafts and rods are sealed;

- transfer boxes contain an oil seal at each of the inputs and outputs;

- drive axles are sealed along the shank and axle shafts;

- hubs and similar units are also protected by stuffing box seals that protect grease;

- closed bearings with rubber-metal washers are used;

- the cooling system pump is closed by a very complex and responsible type-setting stuffing box.

All sliding or rolling friction units must be closed to the external environment in order to maintain the presence and cleanliness of the lubricant. Cuffs do the same thing, but more often it concerns hydraulics.

For example, shock absorbers, aggregate control rods, steering and brake system components.

How to choose a main oil seal for an internal combustion engine

The easiest way is to use original parts. Their order number can be found in the spare parts catalog for the specific vehicle. But after the acquisition, one has to notice that in the original packaging there is a part marked with one of the popular component manufacturers.

You can save a lot without losing quality if you purchase this product in the manufacturer's packaging.

The quality of manufacturing rubber reinforced products is not constant. Firms change technologies, not always for the better, launch new product lines, locate production in countries with more favorable economic conditions.

However, some products can always be trusted. Without arranging them in the order of consumer rating, since it is unrealistic to conduct it objectively. You will either have to overpay, or waste time on a long delivery of an unpopular product.

For example, many Asian car manufacturers install Nok and Kos products on the assembly line. They are also sold as original. This does not mean that this choice is the best, but they can be bought, they will be inexpensive and will work out their time.

Popular and reliable seals Corteco, Victor Reinz, Elring. There are several brands that pack cheap Asian goods, but due to quality control they are quite reliable.

They do not differ in a long service life, but they belong to the economy option. Approximately the same products can be purchased under the brand name of the direct manufacturer, but here it is difficult to talk about the stability of quality. Sometimes they serve no worse than branded ones, sometimes they flow right away.

The price can serve as a fairly accurate criterion. Cheap things are rarely good. And the reverse situation - exorbitant cost often speaks not of quality, but of a small volume of output.

Therefore, it is always worth comparing products of the same size and tolerance, but from different well-known companies. There is almost always a choice here and it is quite wide. The exception is rare and expensive cars.

How to replace the crankshaft seals between the gearbox and the engine

This oil seal is often called the main one, although it is not clear why, apparently out of respect for the laboriousness of the replacement.

To access the oil seal, you will have to remove the gearbox and clutch, if any, in accordance with the technological instructions for a particular car. Access to the engine flywheel will open, which must also be dismantled. There is no need to drain the oil, the oil seal is above its level.

The old oil seal is easily pry off with a screwdriver, in difficult cases you can screw a self-tapping screw into it, pull it out for it. It is better to coat the new one on the outside with sealant, cover the edge with grease. Carefully put it on the shaft without damaging the edge and without losing the preload spring. You can press it to the place with a mandrel or an old oil seal.

Watch this video on YouTube

Sometimes the design allows a slight offset of the edge along the shaft so that it can work on a non-worn surface.

But if this is not possible, and the groove is too large, during the overhaul it is necessary to spray metal on the shaft neck and grind it. Otherwise, the new seal will leak no less than the old one.