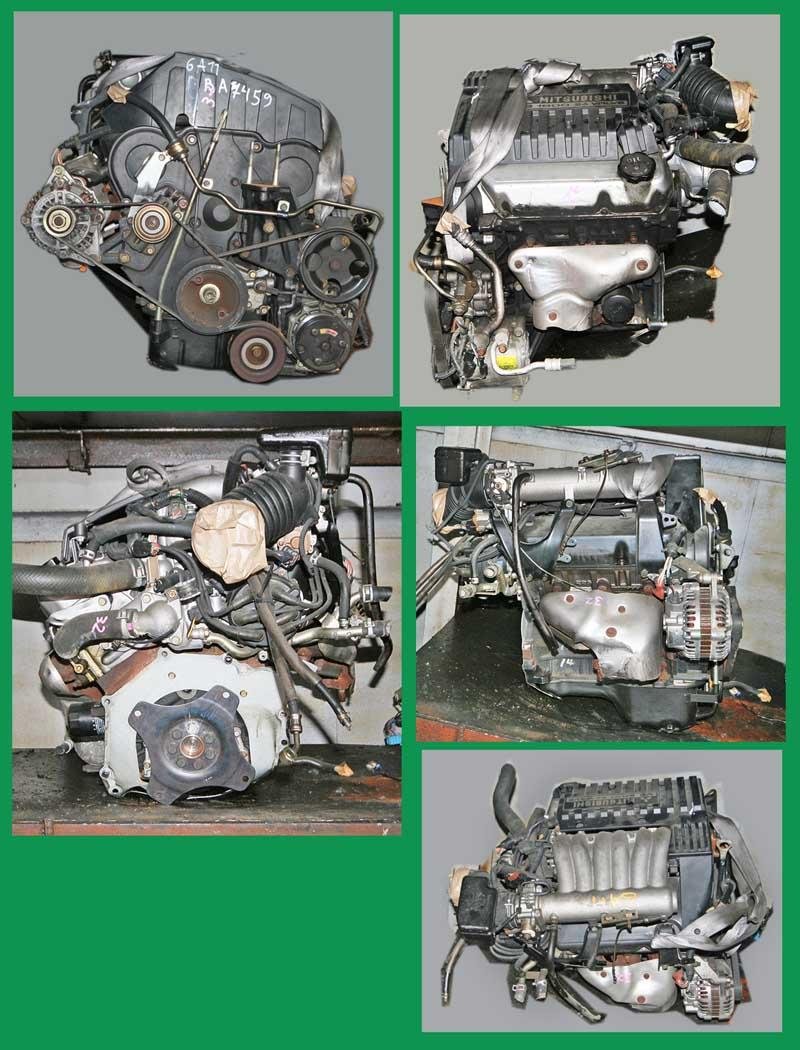

Mitsubishi 6A11 engine

Content

The 6A11 power plant is known to us thanks to the Mitsubishi Galant car on which it was installed. This is a 1,8-liter "six", capable of developing 133 hp. With.

Description

The A-series engines are V-shaped six-cylinder units. They were equipped with small and medium-sized vehicles in the 90s of the last century. The volume of engines varied between 1,6-2,5 liters, power plants were made with various cylinder head configurations.

6A11 refers to the SOHC variant. Here are the specifications that make this engine stand out:

- V-shaped design;

- cast iron cylinder block;

- aluminum cylinder head;

- 6 cylinders;

- 24 valves;

- fuel system - ECI Multi;

- optimal power - 99 kW or 135 liters. s./6000 rpm;

- optimal torque - 167 Nm;

- displacement - 1829 cubic meters. cm.

The 6A11 engine was installed on Mitsubishi Galant, Eterna, Emeraud and Mitsubishi Mirage cars.

| Engine displacement, cc | 1829 |

| Maximum power, hp | 135 |

| Maximum torque, N * m (kg * m) at rpm. | 167 (17) to 4500 |

| Fuel used | Petrol Regular (AI-92, AI-95) |

| Fuel consumption, l / 100 km | 4.9 |

| engine's type | V-twin, 6-cylinder, 24-valve, SOHC, liquid cooling |

| Cylinder diameter, mm | 75 |

| Maximum power, h.p. (kW) at rpm | 135 (99) to 6000 |

| Compression ratio | 10 |

| The piston stroke, mm | 69 |

| What cars did you install it on? | Mitsubishi Émeraud sedan 1st generation, Mitsubishi Éterna sedan 5th generation, Mitsubishi Galant 7th generation, Lancer 5th generation, Mirage 5th generation |

Typical problems and malfunctions

The 6A11 engine has various problems that owners have to deal with. Let's consider them in more detail.

- Valves are knocking.

- The engine uses a lot of lubricant.

- The turnovers are floating.

Valves

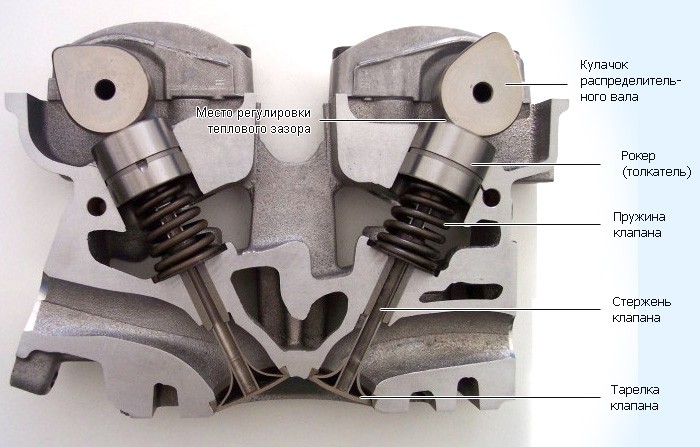

Valve knocking on a cold or hot engine is a common problem with its own causes. It's okay if this happens because of the need to regulate these mechanisms. Such adjustment is required by the valves regularly, after a certain time.

But you should be wary in cases where the valves knock for reasons:

- natural wear of the motor, which occurs after the operational warranty period;

- due to an excessive increase in the gaps between the camshaft cam and the lever;

- due to excessive reduction of gaps or tightness of valves that are unable to fully close.

Thus, violation of thermal gaps is the main cause of valve knock. The backlash can be large or small.

As for the knock of valves on a cold one, when the noise disappears as the engine warms up, experts will explain this simply. The motor is outdated, the parts are worn out, the cold gaps are increased, but when the temperature inside the engine rises, the parts expand and the gaps return to normal. Accordingly, the noise also disappears.

Another cause of valve knocking on a cold engine is pusher wear. Dirt and oil deposits can form in the area of this part. This reduces the efficiency of the lubricant supply, as a result of which, until a certain warm-up, which helps soften the layers, a sonorous metallic sound is heard - clatter.

Other causes of valve knock:

- play in the camshaft area and the development of rockers;

- reduction of oil pressure in the lubrication system;

- engine detonation.

Knocking valves indicates an early solution to the problem.

Increased oil consumption

Zhor oil — already abnormal. The engine should not consume oil, because it is a lubricant that is designed to soften friction between metal elements. What kind of expense can we talk about?

It turns out that the most logical cause of oil consumption is a leak. Some seals fail, can no longer withstand pressure, and a certain amount of lubricant begins to flow out of the system. As the operation progresses, the leakage increases, respectively, it is necessary to fill the engine with oil more often.

Oil seals, in fact, are valve stem seals that tend to harden over time. Old caps are changed, and everything starts working again, without leaks and oil consumption.

Another reason is related to the wear of the oil scraper rings. As you know, from the storage for the lubricant - the crankcase - oil is sprayed under pressure on the walls of the cylinders (due to the rotation of the crankshaft). After this action, the oil should be completely removed from the surface of the cylinders by rings. However, if the oil scraper elements are worn out, do not cope with their functions, part of the lubricant remains on the walls, and the piston pushes oil into the combustion chamber during the next cycle, which should not be. It is obvious that it burns there. If we take into account that the crankshaft makes about 800 rpm, then during this time there are about 3200 working cycles, of which 1600 (half) is pushing the piston up.

Thus, the occurrence or wear of oil scraper rings is the cause of increased consumption, or rather, combustion of oil. This problem is especially relevant for 6A11 with shortened pistons. This affects the deterioration of heat dissipation. After the occurrence of the rings, the situation is aggravated by the fact that the lubricant is coked even more.

Floating revolutions

Jumping engine speed is a signal hinting at engine problems. They should be correctly diagnosed and repaired. The fact that the engine has trouble with speed can be understood not only by the characteristic noise, but also by the tachometer needle. During the stable operation of the motor installation, the arrow is kept at the same level - 750-800 rpm. On the contrary, if it jumps - then it rises, then it drops sharply - this is a signal of unstable operation.

Most often, problems with revolutions occur in idle mode. This also happens in transient conditions, although this is more typical for diesel engines rather than gasoline engines (6A11). Therefore, consider the jumps in speed at the twentieth.

In this case, the correct settings of the XX system, controlled on Galant, Emeraud and Etern by an electronic control unit, are of primary importance. The computer usually reads data about the operation of the system through sensors - if there is a malfunction, an order is given to correct the situation. For example, if excess air enters the fuel system, then the DMRV (air sensor) signals this to the computer. To correct the situation, the “brains” will send a command to the injectors to open wider to inject more fuel, thereby normalizing the fuel-air mixture. Having received a lot of gasoline, the engine will a priori increase the speed, but the “order” of the ECU will not last long, and soon the amount of fuel supplied will normalize, and the speed will also decrease. Such functioning is called unstable.

The second reason is a malfunction of the IAC. This is a sensor that directly controls idle speed. In fact, this is a motor with a conical needle, the main function of which is to stabilize the speed. The cause of its failure must be sought in the banal mechanical wear of the needle or guides, broken wiring, etc. Thus, with a faulty IAC, the engine is left without a stabilizer, and begins to "mindlessly" increase or decrease speed.

Another reason for a jump in speed is a breakdown or contamination of the lubricant crankcase ventilation breather. During operation, crankcase gases accumulate on the fitting. The older the engine, the more clogged this valve. The engine speed is associated with this part for the reason that the fuel assembly is not fully enriched and less exhaust gases enter the intake.

Swimming speed at the twentieth can occur due to the release of the DMRV. In the process of long-term operation, this sensor is also contaminated, which leads to its breakdown. Without the DMRV, the electronic control unit does not receive reliable information, therefore it gives incorrect commands.

Finally, the speed may jump due to incorrect operation of the throttle valve, which is responsible for adjusting the air pressure. The damper can jam for several reasons, but as a rule, it becomes dirty and cannot close properly.

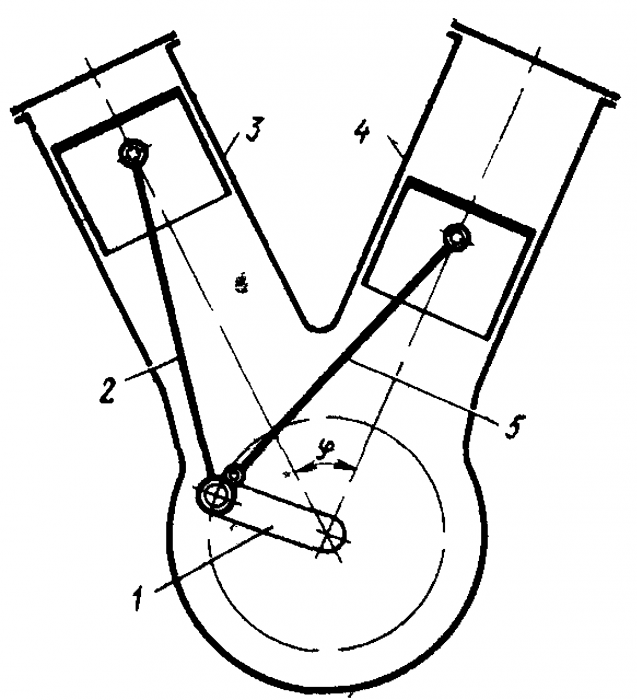

V-shaped engines

In principle, V-shaped “sixes” are more reliable than in-line ones, but the number of typical “diseases” does not decrease from this. Due to the design features, such motors are inconvenient to maintain. For example, it is difficult to change candles, which need to be replaced more often in Russia and the countries of the former CIS due to the low quality of fuel. Misfires often occur due to deposits on the electrodes. Access to the timing belt is no less difficult.

The V-shaped engine can be considered a logical result of the overall development of the engine line. Despite the complex design, this is one of the best types of engines, as it allows you to use a large number of cylinders in a small space. In other words, the appearance of the V-shaped engine is associated with the search for the most compact design in the engine compartment of the vehicle.