Mitsubishi 6G71 engine

Content

This is a rare engine, its volume is 2.0 liters. Fuel consumption is small, but increases over time, depending on the car: 10-15 liters in the city, and 5-9 liters on the highway.

Description

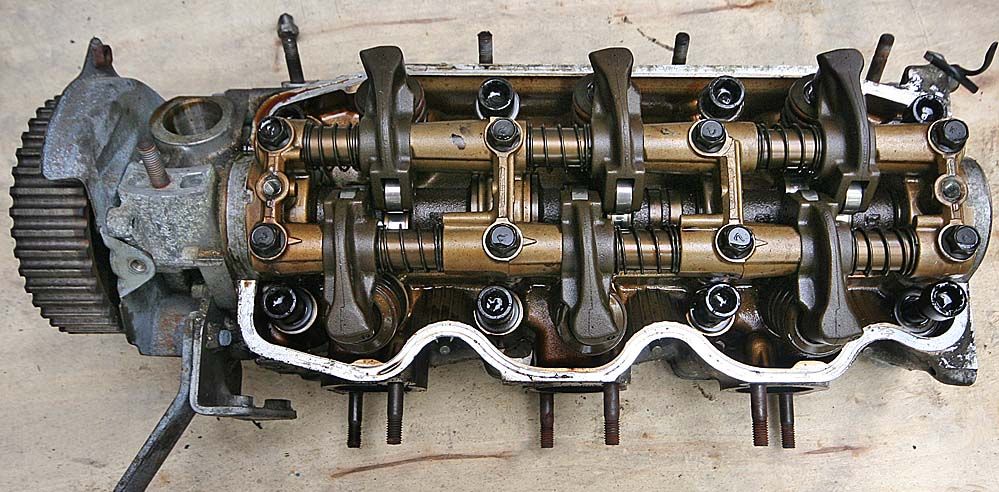

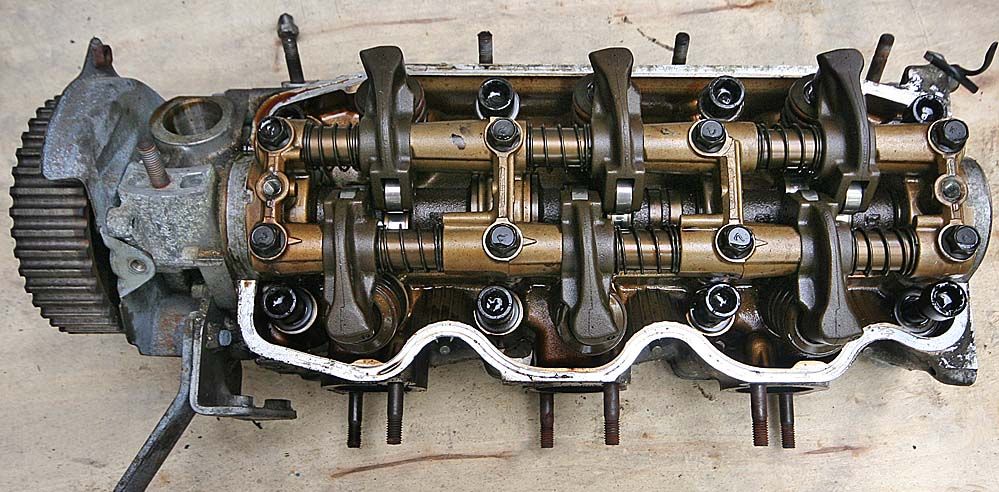

The 6G series engines are piston power units designed exclusively for MMC vehicles. V-shaped "sixes" with one or two camshafts located on top. The motors of this series have a one-piece crankshaft and an aluminum manifold.

The 6G71 uses a single camshaft, which is similar to SOHC, developing peak 5500 rpm. The compression ratio is 8.9:1.

You can call this power plant a powerful six-cylinder unit, because it was not in vain that it stayed on the conveyor for a long time. The engine has proven to be a very reliable, economical and easy to maintain option. Due to its high performance, the 6G71 enjoys well-deserved love and respect among the owners of Japanese Mitsubishi cars.

The 6G71 engine has been constantly improved. Almost every year it was subjected to various upgrades, which explains the large number of its modifications.

- In the 80s, 6G71 and 6G72 were introduced. They represented the debut of a new line of injection 6-cylinder units.

- Soon the line was expanded with three more engines, widely used on various cars - not only Mitsubishi, but also on some American cars under license.

V-shaped cast-iron "six" differed from analogues. Firstly, this is a modified camber angle of 60 degrees. Secondly, the cylinder head of new engines was made of aluminum, which made it possible to significantly lighten the design and increase temperature resistance.

The most popular was the 3,5-liter 6G74 unit, exactly copied from the 6G71. But thanks to the upgrades, it turned out to be more reliable, economical and easy to maintain. It was also equipped with a timing belt drive, which had to be changed every 70 thousand kilometers of the car. The Americans fell in love with these engines - they began to install them on their SUVs.

| OPTIONS | VALUE |

| Years of issue | 1986 – 2008 |

| The weight | 200 kg |

| Cylinder block material | cast iron |

| Motor power system | Injector |

| Cylinder arrangement type | V-shaped |

| Engine displacement | 2 cm972 |

| Engine power | 143 l. With. 5000 rpm |

| Number of cylinders | 6 |

| Number of valves | 12 |

| Piston stroke | 76 millimeters |

| Cylinder diameter | 91.1 millimeters |

| Compression ratio | 8.9 atm |

| Torque | 168 Nm / 2500 rpm |

| Environmental standards | EURO 4 |

| Fuel | 92 gasoline |

| Fuel consumption | Xnumx l / xnumx km |

| Oil | 5W-30 |

| Crankcase Oil Volume | 4,6 liters |

| When replacing the casting | 4,3 liters |

| Oil change is carried out | Every 15 thousand km |

| Motor life | |

| - according to the plant | 250 |

| - on practice | 400 |

The 6G71 engine was installed mainly on the Mitsubishi Diamant.

Video: about the 6G72 engine

Problems

There are many known problems with the 6G71 engine, although in general it is a reliable engine. However, time, an unprofessional attitude, the use of non-original parts and low-quality fluids can take their toll.

High oil consumption

A popular "sore" of old engines. The problem is caused by valve stem seals that require replacement at the first symptoms of a malfunction. But there are certainly other reasons as well.

Oil is a consistency designed to slow down the wear of engine components. It is contained, circulates in a closed hermetic circuit. Moving, the lubricant cools all moving and rubbing engine parts, lubricates their surfaces. A clear signal that the 6G71 is eating a lot of oil is the extensive nature of the stains under the car, increased smoke exhaust, and refrigerant foaming.

A serviceable engine should consume oil in the range of 20-40 g/1000 km of vehicle run. The increase in consumption may be due to the obsolescence of the car or during the operation of the engine in difficult conditions, but even then it will not exceed 200 g / 1000 km. If the engine consumes liters of oil, this is a clear sign of a malfunction that requires an immediate solution.

The first thing to do when detecting increased consumption is:

- measure the temperature of the engine, because when overheated, scuffs appear on the cylinders, caps fail, irreversible changes occur inside the motor;

- check the viscosity of the oil, since an improperly selected lubricant causes damage to the components and elements of the internal combustion engine, contributes to squeezing the lubricant into the crankcase;

- test valve stem seals;

- check the channels in the forced crankcase ventilation system and valves - faulty valves cause an increase in pressure, punching seals;

- check the fixation of the engine bolts, the loosening of which increases the risk of leaks;

- check all cuffs, seals and gaskets;

- pay special attention to checking the cylinder head gasket.

Elimination of the consequences of increased oil consumption is almost always associated with the dismantling and disassembly of the engine.

Hydraulic compensators

Another well-known engine problem is hydraulic lifters. They need to be replaced as soon as extraneous knocks appear in the internal combustion engine that are not associated with the cranking of the connecting rod bearings. It is customary to distinguish between knocks of hydraulic lifters on a cold or hot engine. For example, if they only knock on a cold engine, then the noise disappears as it warms up, there is no reason to worry. But if the sounds continue on a hot engine, this is already a reason to intervene.

6G71 hydraulic lifters are a plunger pair interacting with a lubricant.

The main causes of element knocking are associated with mechanical wear, malfunctions in the lubrication system and bad oil.

- In the process of work, defects appear on the surface of the hydraulic compensators, they are produced.

- If the oil is contaminated, then the parts described are quickly contaminated, which leads to the sticking of the lubricant supply valve. In the event of a lack of lubricant, the hydraulic lifters will be subjected to high loads, begin to knock and can easily break.

As it was written above, a distinction is made between constant and intermediate knocking of parts. If they knock when starting the engine, on a cold one, the noise is not considered a sign of a malfunction - this is just insufficient oil viscosity. As you know, cold grease does not have the desired viscosity, but as it warms up, it liquefies and knocks disappear.

If the noise bothers and does not suit the owner, then you can change the oil. It is recommended to switch to a more expensive and high-quality lubricant option in order to completely eliminate the knocking of hydraulic lifters on a cold engine.

Thus, hydraulic lifters can knock on a cold one, and not cause any particular difficulties, in these situations.

- Does not hold the hydraulic lifter valve. Oil in this case will flow out, air will enter the system. After starting the internal combustion engine, as the oil warms up, it will force out the air, the knocks will stop.

- The channel supplying oil to the hydraulic lifters is clogged. The knock disappears with warming up because the liquid lubricant passes through the system more easily, dirt does not stop it. But over time, the channels will become even more clogged, and the knocks will not disappear with the engine warming up. Therefore, it is recommended already at this stage to deal with the problem - to apply special compounds (additives for hydraulic lifters).

Now about what to do if the knock does not stop. The list of causes of malfunctions in this case is much wider. In addition, the knock of hydraulic lifters on a hot engine can be determined by the nature of the sound. It resembles the blows of a steel ball, and its localization is noticeable under the valve cover.

So here's the list of reasons.

- The channels are completely clogged, dirt blocks the supply of lubricant. The solution is only flushing, no additives will help.

- The oil filter has deteriorated. Because of this, there is no pressure in the system, knocks appear. The solution is to check the device, replace if necessary.

- The engine oil level is critical. It makes no difference whether the lubricant is less than normal or more. In both cases, a knock will appear, since both the lack of lubrication and its excessive amount affect the hydraulic lifters negatively.

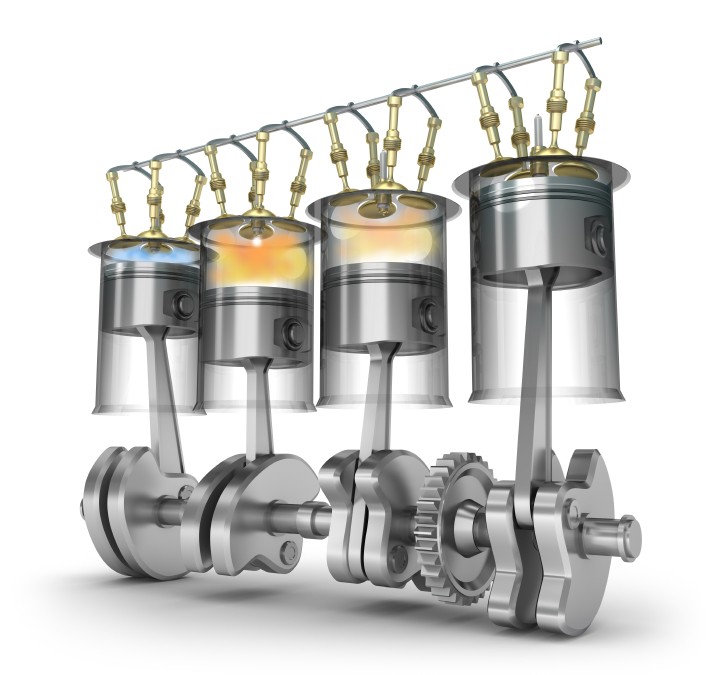

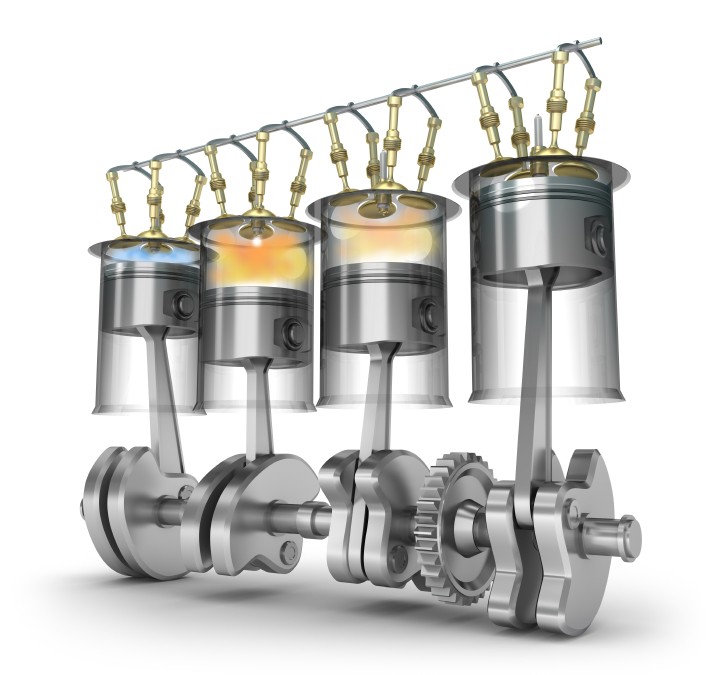

Pistons and valves colliding: broken timing belt

Particular attention in the course of improving the engine was paid to the device of the piston group and the combustion chamber. The modernization was carried out several times, the goal is to increase the filling of the cylinders and their ventilation, having improved gas exchange.

Thus, the latest modifications of the 6G engine turned out to be technically advanced compared to their predecessors. However, this has become an Achilles' heel. The large engine power and its improved technical characteristics have become the reason for a shorter resource.

It is noteworthy that in order to achieve greater returns from the engine, the distance from the piston to the valve is made minimal. Because of this, the valves bend when the piston rises to TDC.

Engine timing belt drive. When the belt breaks, the pistons collide with the valves, and this threatens to overhaul. I must admit that it is expensive. Therefore, owners of cars equipped with this engine are required to carry out service work to replace the belt every 50 thousand kilometers.

Remember that the belt should not have any delaminations, cracks or other defects. The ingress of engine oil or other technical liquids is also not allowed. The main sign of a problematic timing belt is a creak, squeak, or other characteristic noises that are not related to the tension of the belt drive.

The specific timing for replacing the timing belt depends on the condition of the car itself, and not just the engine. For example, on new cars, the belt can be checked after 60-70 thousand kilometers. After that, the verification period must be reduced, since all the mechanisms of the car, including elements of the timing system, become obsolete. The next check and replacement should be carried out after 40-50 thousand kilometers.

The quality of the product is of great importance. Original belts run longer, analogues should be chosen with great care, as you can always come across "china".

As for the reasons why the belt on the 6G71 engine can break:

- wedged one of the shafts (camshaft / crankshaft);

- jammed water pump (pump);

- the tension roller has moved, the belt touches sharp edges during rotation and breaks ahead of time.

And of course, the belt can become obsolete and tear after prolonged use or as a result of oil getting on its surface.

Valves are the weak point of the engine. They collide with pistons also because of the following.

- Overspeed, resulting in a situation where the valve springs do not have time to move the parts back, the pistons collide with one or more valves.

- An incorrect adjustment was made after the next engine repair or due to excessive tightening of the idler roller. In this case, the GRS phase settings fail.

- The connecting rod bearing has worn out or the connecting rod bolts have loosened, so the play has increased.

- The valve offset from the head plane has not been adjusted. This happens after grinding the cylinder head.

Correcting the problem depends on the specific cause: the GRS phases are correctly adjusted or the clearance on all cylinders is controlled.

Bent valves cannot be used further. Only their replacement will help, and for this it is necessary to remove and disassemble the engine. Valves consist of two parts: a plate and a core. During a belt break, it is the rod that gets hit, it bends, bends.

Now more about the process. As you know, after a broken belt, the camshaft stops abruptly. The crankshaft continues to rotate. The valves are recessed into the cylinders and collide with the pistons when the latter reach TDC. The pistons move at high speed, so they can easily bend or break valves on impact. Simultaneously with the valves, the timing mechanisms, cylinder head and other elements fail.

Other malfunctions 6G71

In addition to the above problems, there are also the following.

- Turnovers float, keep unstable. In most cases, this malfunction is associated with the IAC. After replacing the sensor, the operation of the motor stabilizes.

- Decreased power of the unit. The situation necessarily requires a compression test. In many cases, this is an occasion for major repairs.

- Interruptions in the operation of the engine. There can be two reasons: spark plugs are damaged or the intake manifold is faulty.

Modernization

The 6G71 engine is often tuned, as it makes it possible to do this and has great potential. First of all, the control unit is flashed. New electronics can increase engine power by an extra 20 hp. With.

The use of a turbine and a front intercooler is considered as an extreme tuning option. Modernization will require a maximum of alterations: it will be necessary to replace the fuel pump, install a boost controller, as well as a number of other elements. It is also important to use apply kit kits. If you fully engage in this type of tuning, then you can increase the power up to 400 hp. With.