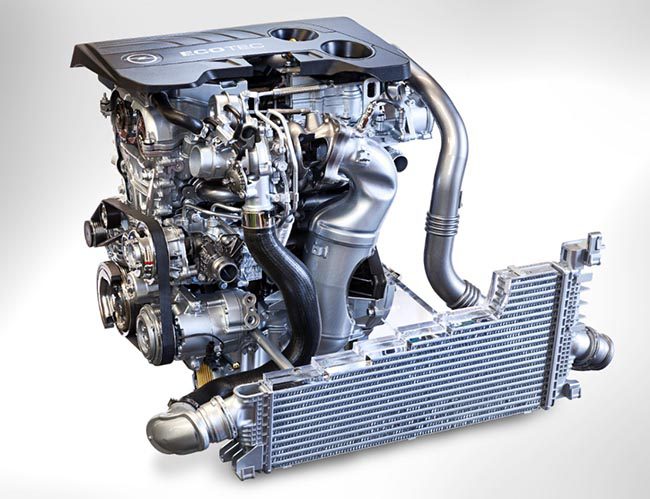

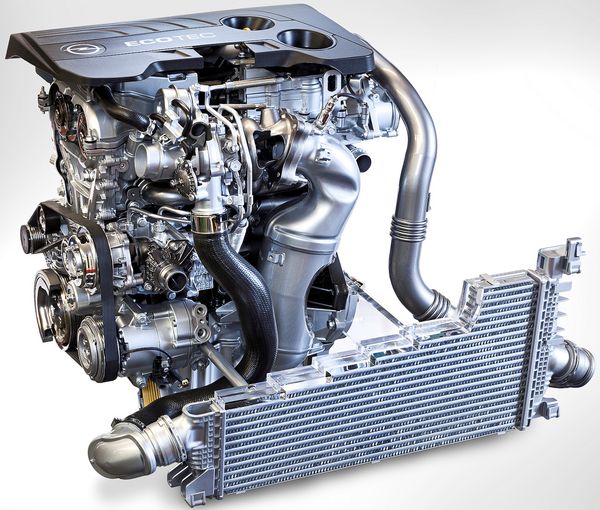

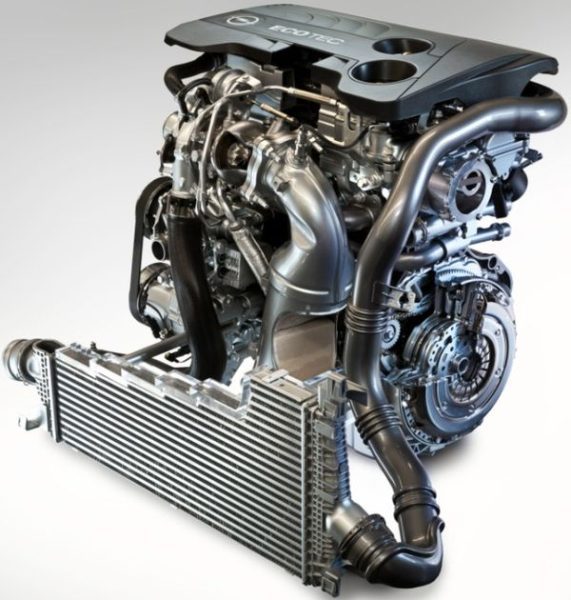

Opel 1,6 SIDI Turbo Ecotec engine (125 and 147 kW)

The first car to receive the new 1,6 SIDI turbocharged direct injection engine was the Opel Cascada convertible. According to the automaker, this engine should be the leader in its class in terms of consumption, performance and culture of operation.

The first car to receive the new 1,6 SIDI turbocharged direct injection engine was the Opel Cascada convertible. According to the automaker, this engine should be the leader in its class in terms of consumption, performance and culture of operation.

Opel's first petrol engine with direct petrol injection was the 2,2 kW 114 ECOTEC four-cylinder engine in 2003 in the Signum and Vectra models, which was later used in the Zafira. In 2007, the Opel GT convertible received the first 2,0-liter turbocharged four-cylinder direct injection engine with 194 kW. A year later, this engine began to be installed on the Insignia in two versions with a power of 162 kW and 184 kW. The new Astra OPC has received the most powerful version with a capacity of 206 kW. The units are assembled in Szentgotthard, Hungary.

The 1,6 SIDI engine (spark ignition direct injection = spark ignition direct fuel injection) has a cylinder displacement of 1598 cc. See and, in addition to direct injection, is also equipped with a start / stop system. The engine is available in two power variants 1,6 Eco Turbo with 125 kW with a maximum torque of 280 Nm and 1,6 Performance Turbo with 147 kW and a maximum torque of 300 Nm. The lower power version is optimized in terms of fuel consumption, has high torque at low speeds and is flexible. The more powerful version is designed for more active motorists who are not afraid to get the most out of their dad.

At the heart of the new SIDI ECOTEC Turbo engine range is a completely new cast iron cylinder block capable of withstanding the highest cylinder pressures up to 130 bar. In order to reduce weight, this cast iron block is supplemented with an aluminum crankcase. The engine block is made using thin-wall casting technology, which allows various functions and elements to be integrated directly into the casting, which reduces production time. The concept of interchangeable elements makes it easier to use the new engine in different model ranges. The engines are also equipped with balancing shafts, which are the only ones in their class so far. Two balancing shafts are located in the rear wall of the cylinder block and are driven by a chain. The purpose of counter-rotating shafts is to eliminate the vibrations that occur during the operation of a four-cylinder engine. The Eco Turbo and Performance Turbo versions differ in the pistons used, namely the specially shaped combustion chamber in the piston head. The first piston ring has a PVD (Physical Vapor Deposition) coating that reduces friction losses.

In addition to design changes, the direct in-cylinder petrol injection system also reduces fuel consumption (i.e. emissions). The spark plug and injector are located in the center of the combustion chamber in the cylinder head to further reduce the outer dimensions. This design also helps to improve the uniformity or layering of the mixture. The valve train is driven by a maintenance-free, hydraulically tensioned chain, and the pulley rocker arms contain hydraulic clearance.

The 1,6 SIDI engines use a turbocharger built directly into the engine exhaust manifold. This design has already proven itself with other Opel engines and is advantageous in terms of footprint as well as manufacturing costs as it is simpler compared to Twin-Scroll turbochargers used in larger engines. The turbocharger is designed for each power version separately. Thanks to the redesigned design, the engine delivers high torque even at low revs. Also, work has been done to suppress unwanted noise (whistling, pulsation, noise of air flowing around the blades), including thanks to low and high pressure resonators, optimized air conductivity and the shape of the inlet channels. To eliminate the noise of the engine itself, the exhaust pipe was modified, as well as the valve manifold cover on the cylinder head, on which special pressure elements and seals were applied that are resistant to the high temperatures of the adjacent turbocharger.