Renault K9K engine

Content

The beginning of the XNUMXst century was marked by the creation of a new engine, which later became widespread, by the French engine builders of the Renault automaker. It turned out to be in demand for such famous brands as Renault, Nissan, Dacia, Mercedes.

Description

In 2001, a new power unit was put into production, which received the code K9K. The engine is a diesel in-line four-cylinder turbocharged engine with a wide power range from 65 to 116 hp with a torque of 134 to 260 Nm.

The engine was assembled at engine factories in Spain, Turkey and India.

The power unit was installed on Renault cars:

- Clio (2001-n/vr.);

- Megane (2002-n/vr.);

- Scenic (2003-n/vr.);

- Symbol (2002);

- Kangoo (2002-present);

- Mode (2004-2012);

- Lagoon (2007-2015);

- Twingo (2007-2014);

- Fluence (2010-2012);

- Duster (2010-year);

- Talisman (2015-2018).

For Dacia cars:

- Sandero (2009-n/vr.);

- Logan (2012-present);

- Dokker (2012-present);

- Lodgy (2012-present).

For Nissan vehicles:

- Almera (2003-2006);

- Micra (2005-2018);

- Tiida (2007-2008);

- Qashqai (2007-n/vr.);

- Notes (2006-n/vr.).

For Mercedes cars:

- A, B and GLA-Class (2013-present);

- Citan (2012-present).

In addition to the listed models, the engine was installed on the Suzuki Jimny from 2004 to 2009.

The cylinder block is traditionally made of cast iron. Sleeves are formed inside. The crankshaft bearings are cast in the lower part.

Aluminum alloy cylinder head. At the top of the head is a bed for the camshaft.

The timing is designed according to the SOHC (single-shaft) scheme with a belt drive. The danger of a broken belt is the bending of the valves when they meet the piston.

There are no hydraulic lifters in the engine. The thermal clearance of the valves is regulated by the selection of the length of the pushers.

Pistons are standard, aluminum, with three rings. Two of them are compression, one is oil scraper. The piston skirt is graphite coated to reduce friction. Metal cylinder head gasket.

The crankshaft is steel, rotates in main bearings (liners).

Combined lubrication system. Chain oil pump drive. The volume of oil in the system is 4,5 liters, the brand is indicated in the instruction manual for a particular car.

Turbocharging is carried out by a compressor (turbine), which receives rotation from the exhaust gases. Turbine bearings are lubricated with engine oil.

The fuel supply system includes a high pressure fuel pump, a fuel filter, glow plugs and a fuel line. It also includes an air filter.

Technical specifications

| Manufacturer | Valladolid Motores (Spain) Bursa plant (Turkey) Oragadam plant (India) |

| Engine volume, cm³ | 1461 |

| Power, HP | 65-116 |

| Torque, Nm | 134-260 |

| Compression ratio | 15,5-18,8 |

| Cylinder block | cast iron |

| Number of cylinders | 4 |

| The order of the cylinders | 1-3-4-2 |

| Cylinder head | aluminum |

| Cylinder diameter, mm | 76 |

| The piston stroke, mm | 80,5 |

| Number of valves per cylinder | 2 (SOHC) |

| Camshaft adjuster | no |

| EGR | Yes |

| Hydraulic compensators | no |

| Turbocharging | BorgWarner KP35 BorgWarner BV38 BorgWarner BV39 |

| Diesel particulate filter | yes (not on all versions) |

| Fuel system | Common Rail, Delрhi |

| Fuel | DT (diesel fuel) |

| Environmental standards | EUR 3-6 |

| Location | transverse |

| Service life, thousand km | 250 |

| Engine weight, kg | 145 |

Modifications

Over the years of production, the motor has been improved more than 60 times.

Conditional classification of modifications is carried out according to environmental standards. ICEs of the 1st generation (2001-2004) were equipped with a Delphi fuel system and a simple BorgWarner KP35 turbine. Modifications had an index of up to 728 and 830, 834. Engine power was 65-105 hp, environmental standards - Euro 3.

From 2005 to 2007, modifications of the 9nd generation K2K were made. The fuel injection systems, the exhaust system were improved, the timing for replacing the timing belt and engine oil was increased. An intercooler was installed on the 65 hp version of the engine, which made it possible to increase the power to 85 hp. At the same time, the torque increased from 160 to 200 Nm. The environmental standard has been raised to Euro 4 standards.

The third generation (2008-2011) received a revision of the exhaust system. A particulate filter was installed, the USR system was improved, there were changes in the fuel system. Environmental standards began to comply with Euro 5.

Since 2012, 4th generation engines have been produced. The fuel supply system, USR have undergone changes, the particulate filter and oil pump have been improved. The engine is fitted with a variable geometry BorgWarner BV38 turbine. ICEs of recent years of production are equipped with start-stop systems and urea injection. As a result of the changes, the power of the internal combustion engine has increased. Environmental standards comply with Euro 6.

The basis of the engine remained unchanged. Improvements were made in terms of changing power, torque and compression ratio. A significant role in this was played by the replacement of Common Rail Delphi fuel equipment with Siemens.

Much attention was paid to environmental standards. Equipping some engine modifications with an EGR valve and a particulate filter somewhat complicated the design and maintenance of the internal combustion engine as a whole, but significantly reduced the emission of harmful substances into the atmosphere.

Minor changes affected the timing belt (increased service life before replacement) and camshaft cams. They received a diamond (carbon) coating of the working surface. The difference between the modifications of the internal combustion engine is observed in the connection of the unit with an automatic transmission or manual transmission.

Part of the engine modifications received a useful energy recovery function (during engine braking, the generator generates increased energy and directs it to battery charging).

A brief overview of the main modifications of the K9K is presented in the table.

| Engine code | Power | Year of construction | Installed |

|---|---|---|---|

| K9K608 | 90 hp at 4000 rpm | 2012-2016 | Clio, Capture |

| K9K612 | 75-95 at 3750 rpm | 2012 | Dacia: Dokker, Logan, Sandero, Stepway, Renault Clio |

| K9K628 | 90 hp at 4000 rpm | 2016 | Renault Clio |

| K9K636 | 110 hp at 4000 rpm | 2007 | Kangoo, Scenic III, Megane III |

| K9K646 | 110 hp at 4000 rpm | 2015-n/vr. | Kadjar, Captur |

| K9K647 | 110 hp at 4000 rpm | 2015-2018 | Kadjar, Grand Scenic IV |

| K9K656 | 110 hp at 4000 rpm | 2008-2016 | Mégane II, Scenic III |

| K9K657 | 110 hp at 4000 rpm | 2009-2016 | Grand Scenic II, Scenic III, Megane III Limited |

| K9K700 | 65 hp at 4000 rpm | 2001-2012 | Renault: Logan, Clio II, Kangoo, Suzuki Jimny |

| K9K702 | 82 hp at 4250 rpm | 2003-2007 | Kangoo, Clio II, Thalia I |

| K9K704 | 65 hp at 4000 rpm | 2001-2012 | Kangoo Clio II |

| K9K710 | 82 hp at 4250 rpm | 2003-2007 | Kangoo Clio II |

| K9K712 | 101 hp at 4000 rpm | 2001-2012 | Clio II |

| K9K714 | 68 hp at 4000 rpm | 2001-2012 | Kangoo, Clio II, Thalia I |

| K9K716 | 84 hp at 3750 rpm | 2003-2007 | Kangoo Clio II |

| K9K718 | 84 hp at 3750 rpm | 2007-2012 | Twingo II, Icon II, Clio |

| K9K722 | 82 hp at 4000 rpm | 2002-2006 | Scenic II, Megane II |

| K9K724 | 86 hp at 3750 rpm | 2003-2009 | Scenic II, Megane II |

| K9K728 | 101-106 hp at 6000 rpm | 2004-2009 | Mégane II, Scenic II |

| K9K729 | 101 hp at 4000 rpm | 2002-2006 | Scenic II, Megane II |

| K9K732 | 106 hp at 4000 rpm | 2003-2009 | Mégane II, Scenic II |

| K9K734 | 103 hp at 4000 rpm | 2006-2009 | Megane II, Scenic II, Grand Scenic I |

| K9K740 | 64 hp at 3750 rpm | 2007-2012 | Twingo II, Thalia I, Pulse |

| K9K750 | 88 hp at 4000 rpm | 2004-2012 | Mode I |

| K9K752 | 65 hp at 3750 rpm | 2008-2012 | Modus I, Clio III |

| K9K760 | 86 hp at 4000 rpm | 2004-2012 | Mode I, Grand Mode |

| K9K764 | 106 hp at 4000 rpm | 2004-2008 | Modus, Clio III |

| K9K766 | 86 hp at 3750 rpm | 2005-2013 | Clio III |

| K9K768 | 68 hp at 4000 rpm | 2004-2012 | Mode I, Clio |

| K9K770 | 75-86 at 4000 rpm | 2008-2013 | Clio III, Modus I |

| K9K772 | 103 hp at 4000 rpm | 2004-2013 | Clio III, Modus I |

| K9K774 | 106 hp at 4000 rpm | 2005-2013 | Clio III |

| K9K780 | 110 hp at 4000 rpm | 2007-2015 | lagoonIII |

| K9K782 | 110 hp at 4000 rpm | 2007-2015 | Lagoon III |

| K9K792 | 68 hp at 4000 rpm | 2004-2013 | Dacia: Logan, Sandero, Renault Clio |

| K9K796 | 86 hp at 3750 rpm | 2004-2013 | Dacia: Logan I |

| K9K800 | 86 hp at 3750 rpm | 2013-2016 | Kangoo II |

| K9K802 | 86 hp at 3750 rpm | 2007-2013 | Kangoo II |

| K9K804 | 103 hp at 4000 rpm | 2007-2013 | KangooII, Grand Kangoo |

| K9K806 | 103 hp at 4000 rpm | 2007-2013 | Kangoo II |

| K9K808 | 90 hp at 4000 rpm | 2007-n/vr. | Kangoo II, Grand Kangoo |

| K9K812 | 86 hp at 3750 rpm | 2013-2016 | KangooExpressII |

| K9K820 | 75 hp at 3750 rpm | 2007-2012 | Twingo ii |

| K9K830 | 86 hp at 4000 rpm | 2007-2014 | Twingo II, Fluence, Scenic III, Grand Scenic II |

| K9K832 | 106 hp at 4000 rpm | 2005-2013 | Fluence, Scenic III, Grand Scenic II |

| K9K834 | 90 hp at 6000 rpm | 2008-2014 | Megane III, Fluence, Thalia II |

| K9K836 | 110 hp at 4500 rpm | 2009-2016 | Megane III, Scenic III, Fluence |

| K9K837 | 110 hp at 4000 rpm | 2010-2014 | Megane III, Fluence, Scenic III |

| K9K840 | 68 hp at 4000 rpm | 2007-2013 | Kangoo II |

| K9K846 | 110 hp at 4000 rpm | 2009-n/vr. | Clio IV, Megane III, Lagoon, Grand Tour III |

| K9K858 | 109 HP | 2013 | DaciaDuster I |

| K9K892 | 90 hp at 3750 rpm | 2008-2013 | Dacia Logan |

Reliability, weaknesses, maintainability

The technical characteristics will be supplemented by the main factors characterizing the operational capabilities of the internal combustion engine.

Reliability

On the reliability of the K9K engine, the opinions of its owners were divided. Many do not have any claims against him, and some express regret that they got this particular motor.

The practice of operating the engine shows that both categories of motorists are right in this matter.

With timely and high-quality maintenance of the motor, the implementation of all the manufacturer's recommendations for its operation, the unit is able to significantly cover the declared mileage resource without any serious damage.

In communication on thematic forums, their participants confirm what was said. For example, Sergey shares his impression: “... drove Laguna 3 with a k9k diesel engine with a mileage of 250k. Now the mileage is 427k. I didn’t change the inserts! ”.

The reliability of the diesel engine is indicated by the fact that many models of cars from different manufacturers were equipped with it for a long time, up to the present day. Another important nuance is that the engine is constantly being improved, which means that its reliability is increasing all the time.

Thus, we can draw an unambiguous conclusion: the K9K is a completely reliable power unit with appropriate handling.

Weak spots

In any engine, you can find its weak points. The K9K is no exception. But, upon closer examination, it turns out that the owner of the car often provokes the emergence of these weaknesses.

Some motorists complain about the rotation of the connecting rod bearings. Yes, there is such a problem. The greatest probability of its occurrence is with a run of 150-200 thousand km.

The cause of the malfunction lies in low-quality oil or an increase in the timing of the next maintenance.

Forum member Sergey confirms this with an example from his own experience: “... There was Fluence, 2010. I drove it myself from Germany in 2015 with a mileage of 350000 (the car was in a taxi). I drove another 4 in Belarus in 120000 years. I changed the oil every 12-15 thousand. I sold it with mileage of 470000, while I didn’t climb into the engine, gearbox and fuel system at all!. He is supported by teammate Yuri: “... You don’t need to write nonsense about inserts! The liners in this engine are killed by a long service interval and frequent burning of the particulate filter, which most often cannot be completed successfully during urban operation. When burning to warm up the soot at the end of the working cycle, additional fuel is injected into the cylinder, which burns out in the soot, which increases its temperature and burns the filter. So this fuel does not completely burn out, settling on the walls of the cylinders through the oil scraper rings, it enters the oil, thereby diluting it, and the liners and the turbine suffer from liquid oil in the first place!

Troubles with Delphi fuel equipment arise when low-quality diesel fuel (DF) is used. The nozzles of the system are prone to rapid contamination. It is enough to clean them after 30 thousand kilometers and this problem will be successfully solved. But, given the low quality of our diesel fuel, it is advisable to flush the nozzles more often (after 20-25 thousand km).

A rather delicate knot is considered to be a high-pressure fuel pump. In it, malfunctions occur due to poor-quality diesel fuel or untimely replacement of the fuel filter. The content of pump wear products in the fuel also contributes to the rapid wear of the injection pump plunger pairs. A faulty injection pump is best replaced with a new one, although it can sometimes be repaired.

The turbine requires special attention. It is not uncommon for it to fail in the first hundred thousand kilometers of a car. The cause of the failure is the wear products of the rubbing parts of the CPG, since the oil of the engine lubrication system simultaneously lubricates all the bearings of the turbocharger. To extend the life of the turbine, you need to change the oil and the engine oil filter more often.

The really weak points of the motor are:

- Not a large timing belt resource (90 thousand km). But in 2004 it was raised to 120 thousand km, and from 2008 to 160 thousand km. In any case, the belt requires the closest attention, since its breakage causes bending of the valves. And this is a serious engine repair.

- Lack of hydraulic lifters. You have to resort to the services of a service station more often regarding the adjustment of the thermal clearance of the valves.

- Failure of the DPKV (crankshaft position sensor). The malfunction occurs at high mileage, is eliminated by replacing the sensor.

- The EGR valve and the particulate filter cause quite a few troubles. Most motorists turn off the valve, cut out the filter. The engine only benefits from this, however, due to the reduction of environmental standards.

As you can see, the vast majority of weaknesses can be easily neutralized by following the manufacturer's recommendations for servicing internal combustion engines.

Maintainability

Assessing the maintainability of the motor, it is necessary to emphasize its high cost. Particularly budgetary are the repair of the fuel system and the turbine. The high cost of restoration is based on the replacement of these elements with new ones. Additionally, the problem with the repair of the Common Rail fuel system is that not every service station undertakes its restoration by repairing failed elements due to the lack of experienced specialists.

At the same time, in the reviews of the members of the forum you can find interesting statements. Ruslan writes: “... I have a Delphi injection pump and I’m not going to change it to Siemens or Bosch. Delphi is not as bad as they say about it, its plus in maintainability, which cannot be said about Siemens and Bosch ".

The particulate filter is expensive. It cannot be repaired, only replaced.

In all other cases, there are no problems with restoring the engine. The cast-iron block allows you to bore the cylinders to the required repair dimensions.

Spare parts can always be purchased in specialized or online stores. In the most extreme case - on disassembly. But it is not recommended to overhaul the engine with used parts.

General conclusion: ICE maintainability is good, but costly.

Tuning

Chip tuning of the engine is possible. Flashing the ECU of the 1st and 2nd generation motors (2001-2008) will increase the power to 115 hp, and increase the torque to 250-270 Nm.

Engines of the 3rd generation (2008-2012) will become more powerful by 20 hp. In this case, the torque will reach 300 Nm. These figures correspond to 110-horsepower engines. Modifications of engines with a power of 75-90 hp are upgraded to 110 hp with a torque of 240-250 Nm.

Motors of the 4th generation (after 2012) after tuning will have a power of 135 hp and a torque of more than 300 Nm.

In addition to chip tuning, there is the possibility of mechanical intervention (replacing the turbine with a more powerful one, etc.). But such an operation is expensive and has not been widely used.

It must be remembered that engine tuning significantly increases the loads acting on it. Dependence begins to appear - the greater the load, the less the resource of work. Therefore, before doing engine tuning, you need to think carefully about its possible consequences.

Engine swap

Just a few words on this topic. It is possible, but so costly that it is easier to purchase a contract engine. The complexity of the replacement process lies in the need to change all the wiring, ECU blocks, come up with a motor mount to the body, redo the mounting locations for attachments. The most voluminous positions in terms of labor costs are listed.

A lot of components and parts will have to be replaced with those that were on the car with this internal combustion engine (scene with cables, intercooler, exhaust system, etc.). The purchase of the necessary spare parts through the store will become very costly, and from disassembly - questionable in terms of quality.

Thus, it will simply not be possible to replace one engine without a donor car.

Contract engine

There is no difficulty in acquiring a contract K9K. Many online stores offer used engines of various modifications, with different mileage, year of manufacture and in any completeness.

Sellers give a guarantee for their products (from one to three months).

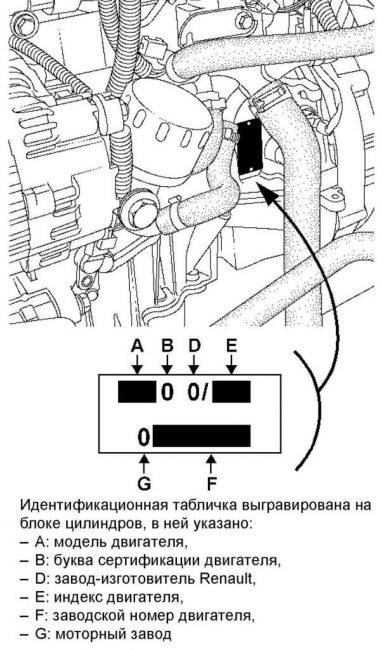

Engine number

Sometimes it becomes necessary to look at the engine number. Not everyone knows its location on the cylinder block. Let's eliminate this gap.

The K9K diesel engine and its modifications is a reliable and durable unit with timely and proper maintenance. Failure to follow all the manufacturer's recommendations will definitely reduce the service life and lead to costly repairs.