Engine VAZ-2104

Content

For the newly created model of the station wagon VAZ-2104, an extraordinary design of the power unit was required.

The development was based on the rejection of the traditional carburetor. Priority was given to the use of a modern fuel injection system.

Description

To call the VAZ-2104 engine a new development would not be entirely correct. The successfully proven VAZ-2103 was taken as the base model of the internal combustion engine. Moreover, the cylinder block, ShPG, timing drive and crankshaft are structurally identical, up to compliance with the dimensions.

It is appropriate to note that initially the basic version of the engine was carbureted, and only later began to be equipped with an injector.

The production of the power unit was established at the Volga Automobile Plant (Tolyatti) in 1984.

The VAZ-2104 engine is a gasoline four-cylinder aspirated engine with distributed fuel injection with a volume of 1,5 liters and a power of 68 hp. with and a torque of 112 Nm.

Installed on Lada cars:

- 2104 (1984-2012):

- 2105 (1984-2012):

- 2107 (1984-2012).

In addition, the engine, without changing design solutions, can be installed on other VAZ models (2103, 2106, 21053) at the request of car owners.

The cylinder block is traditionally cast iron, not lined. Cylinders are bored right in the block, honed.

The crankshaft is also made of cast iron. The shaft bearings are steel-aluminum. From axial displacement it is fixed by two thrust rings - steel-aluminum and metal-ceramic.

Forged, steel connecting rods. The connecting rod bearing caps, like the crankshaft, are not interchangeable.

Pistons are aluminium, tin coated. Cast iron rings. Two upper compression, lower oil scraper. Surfaces treated with chromium (lower compression - phosphated).

Aluminum cylinder head, designed to be equipped with an injection fuel supply scheme. It has enlarged areas for the intake manifold. Provides for the installation of fuel injectors.

The camshaft is one, mounted on five supports. Seats and valve guides are cast iron. Hydraulic compensators are not provided in the timing design, so the thermal clearance of the valves has to be adjusted manually. The cylinder head cover is aluminum, mounted on studs.

The timing drive is a two-row bush-roller chain. It has a damper and a mechanical tensioner with a shoe. In the event of a break in the drive circuit, deformation (bend) of the valves occurs. In the worst case - the deflection of the cylinder head, the destruction of the pistons.

The fuel supply system includes a fuel rail with a pressure regulator and a return (drain) line. Nozzle type - Bosch 0-280 158 502 (black, thin) or Siemens VAZ 6393 (beige, thickened).

During operation, they can be replaced by others with similar parameters. The fuel supply to the rail is carried out by the electric fuel pump module (installed in the fuel tank).

Changes to the ignition system include the use of an ignition module with two high voltage coils and electronic controls. The overall control of the ignition system is carried out by the engine ECU.

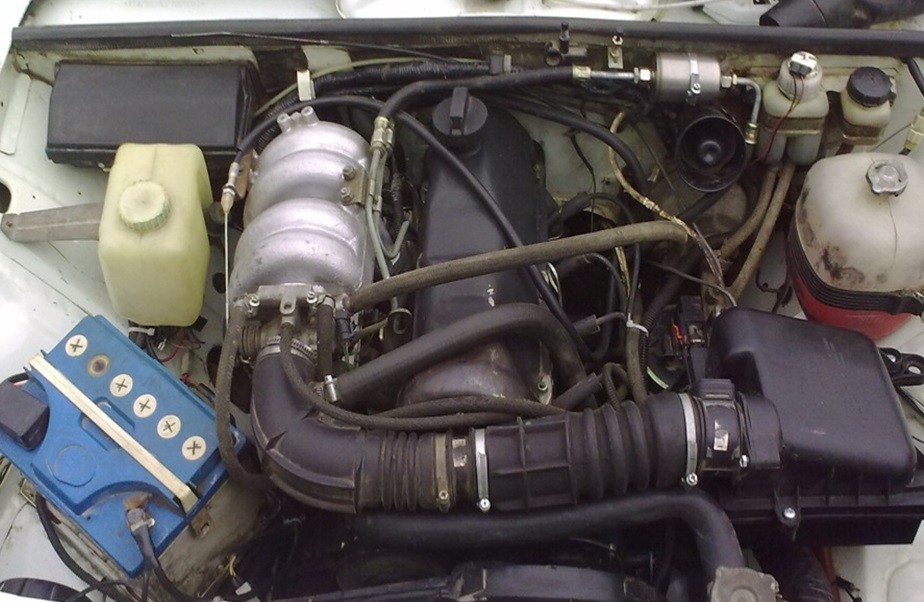

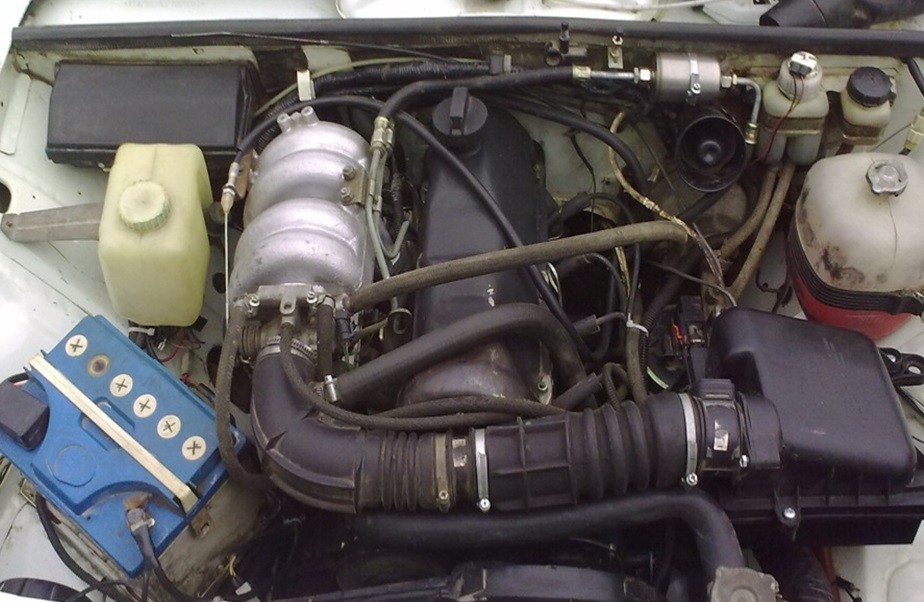

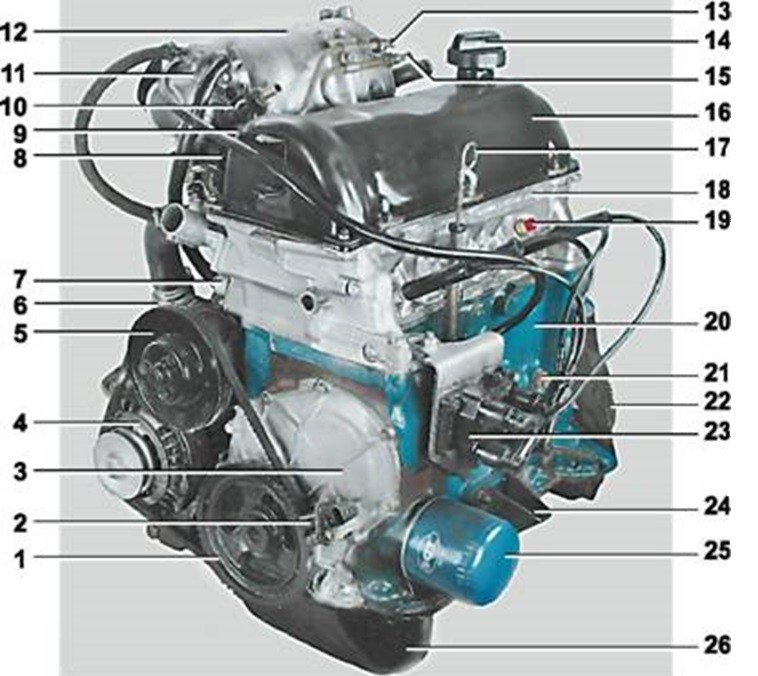

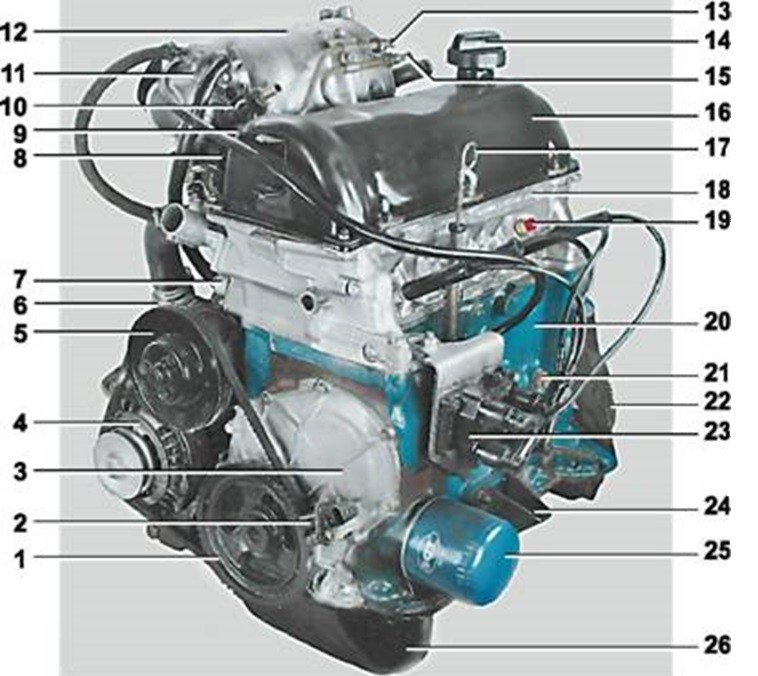

The layout of the main components of attachments is clearly visible in the photo.

1 - crankshaft pulley; 2 - crankshaft position sensor; 3 — a cover of a drive of a camshaft; 4 - generator; 5 - coolant pump; 6 - thermostat; 7 - chain tensioner; 8 - idle speed regulator; 9 - fuel rail; 10 - throttle position sensor; 11 - throttle body; 12 - receiver; 13 - fuel supply pipe; 14 - filler cap; 15 - drain fuel tube; 16 - cylinder head cover; 17 - oil level indicator (dipstick); 18 - cylinder head; 19 - coolant temperature indicator sensor; 20 - cylinder block; 21 - oil pressure sensor; 22 - flywheel; 23 - ignition coil (module); 24 - engine support bracket; 25 - oil filter; 26 - engine crankcase.

VAZ-2104 is rightfully considered one of the most successful AvtoVAZ engines.

Technical specifications

| Manufacturer | Autoconcern "AvtoVAZ" |

| Release year | 1984 |

| Volume, cm³ | 1452 |

| Power, hp from | 68 |

| Torque, Nm | 112 |

| Compression ratio | 8.5 |

| Cylinder block | cast iron |

| Number of cylinders | 4 |

| Cylinder head | aluminum |

| Fuel injection order | 1-3-4-2 |

| Cylinder diameter, mm | 76 |

| The piston stroke, mm | 80 |

| Timing drive | chain |

| Number of valves per cylinder | 2 |

| Turbocharging | no |

| Hydraulic compensators | no |

| Camshaft adjuster | no |

| Lubrication system capacity, l | 3.75 |

| Applied oil | 5W-30, 5W-40, 10W-40 |

| Oil consumption (calculated), l / 1000 km | 0.7 |

| Fuel system | injector, multipoint injection* |

| Fuel | gasoline AI-95 |

| Environmental standards | Euro 2 |

| Resource, outside. km | 125 |

| Weight, kg | 120 |

| Location | longitudinal |

| Tuning (potential), l. With | 150** |

* at the beginning of production, engines were equipped with carburetors; **without reduction of resource 80 l. With

Reliability, weaknesses, maintainability

Reliability

There are many factors that speak to the reliability of an engine. For example, a mileage resource. The manufacturer was modest, defining it at 125 thousand km. In fact, the motor covers it twice. And this is not the limit.

Numerous positive responses from participants in various specialized forums confirm what has been said. The most common are: “… the engine is normal, starts and runs. I don’t go there at all ... I change consumables and drive 60-70 km every day for 4 years... ".

Or "... at the moment, the car has traveled 232000 km, the engine has not yet been sorted out ... If you follow the car, it will drive without complaints ...". Many car owners note the easy start of the engine at low temperatures:… the engine pleases, so far everything is fine, in winter there were no problems with the winding at all, mind you, this is a big plus…».

Equally important is the margin of safety of the internal combustion engine. From the table, when forcing the unit, it is possible to increase its power by more than two times.

But here it should be noted that tuning the motor significantly reduces its resource. If someone really wants to have a stronger engine, then it is better to think about a swap than to remake the native internal combustion engine.

Despite the presence of some shortcomings, the VAZ-2104 is widely popular among motorists. Especially the older generation. They (and not only) learned one important feature - in order for the engine to always be reliable, you need to take care of it.

In other words, careful operation, timely maintenance, high-quality fuel and oil are the key to high reliability.

Weak spots

There are few of them. All of them migrated from the engines previously produced by VAZ. It should be noted that the vast majority of malfunctions occur due to a banal oversight by the car owner.

Engine overheating. The reason lies in a faulty thermostat. If the jamming occurred with the thermostat closed, then the motor overheating will not take long. And vice versa - jamming in the open position will lead to a very long set of operating temperatures. The task of the driver is to detect deviations in the temperature regime of the engine in time. The malfunction is eliminated only by replacing the thermostat.

Stretched timing chain. This phenomenon comes from irregular (after 10 thousand km) chain tightening. The malfunction is characterized by the occurrence of extraneous noise during engine operation. Usually it's valve knocking. Adjusting the valves and tightening the chain fixes the problem.

The problem with starting the engine occurs when there is a malfunction in the electrics of the internal combustion engine. Most often, the fault is a faulty DPKV. The ECU may be failing. Computer diagnostics of the engine at a specialized car service will be able to identify the exact cause of the malfunction.

Often, motorists are annoyed by leakage of working fluids, most often oil. In general, this is a disease of all classic AvtoVAZ engines.

Loose fasteners and broken seals are the cause of all kinds of smudges. Even an inexperienced driver can fix such a malfunction. The main thing is to do this work in a timely manner.

The most common malfunctions of the VAZ-2104 are listed. Their number can be reduced by timely and high-quality maintenance of the internal combustion engine.

Maintainability

Like all VAZ-2104 engines previously produced by VAZ, it has a high maintainability.

The motor is arranged so that it is easy to maintain and repair. This is mentioned by many car owners when communicating on forums.

For example, a message like this: "... all nodes are installed in easily accessible places ...". There are no problems with finding spare parts. On this occasion, Vasily (Moscow) writes as follows: “... minor breakdowns are quickly, and most importantly, cheaply solved ...».

You can carry out repairs at almost any car service or on your own. Some car owners resort to the services of private garage specialists.

True, in this case there is a certain risk - in the event of an unsuccessful repair, such a master does not bear any responsibility.

An alternative to a major overhaul can be the option of purchasing a contract engine. The cost of such a unit depends on the year of manufacture and configuration with attachments, starts from 3000 rubles.

VAZ-2104 turned out to be an extremely successful engine, quite powerful and economical, easy to repair and not demanding in operation. Compliance with the maintenance schedule contributes to a significant excess of the mileage resource.