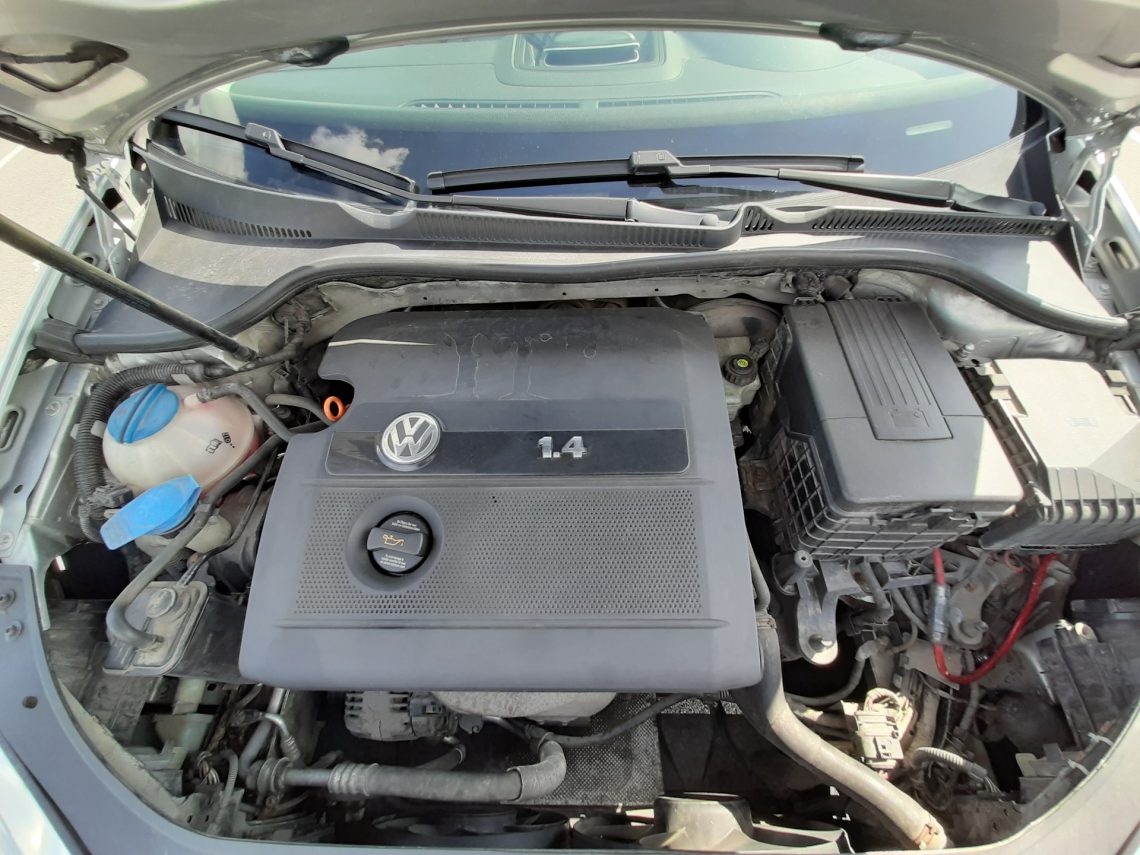

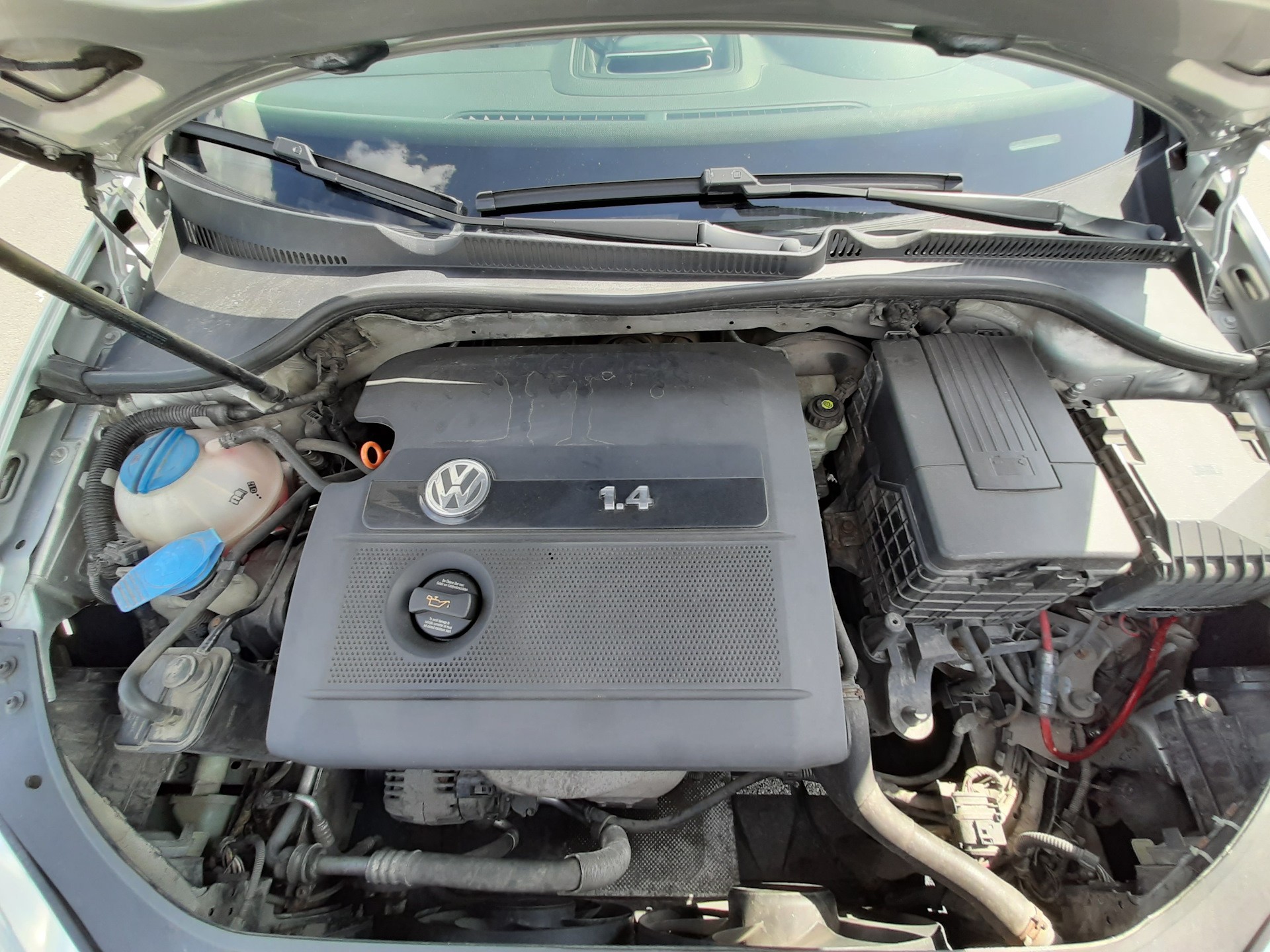

Volkswagen BCA engine

Content

The engine builders of the VAG auto concern offered the consumer a new engine option for popular car models of their own production. The motor has replenished the line of units of the concern EA111-1,4 (AEX, AKQ, AXP, BBY, BUD, CGGB).

Description

Volkswagen engineers were faced with the task of creating an internal combustion engine with low fuel consumption, but at the same time it must have sufficient power. In addition, the motor must have good maintainability, be easy to operate and maintain.

In 1996, such a unit was developed and put into production. The release continued until 2011.

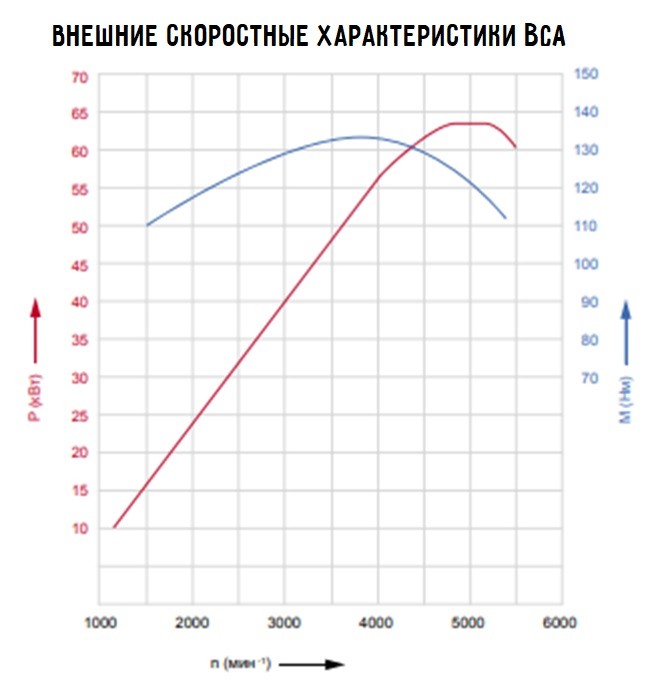

The BCA engine is a 1,4-liter four-cylinder in-line gasoline engine with a capacity of 75 hp. with and a torque of 126 Nm.

Installed on cars:

- Volkswagen Bora I /1J2/ (1998-2002);

- Bora /wagon 2KB/ (2002-2005);

- Golf 4 /1J1/ (2002-2006);

- Golf 5 /1K1/ (2003-2006);

- New Beetle I (1997-2010);

- Caddy III /2K/ (2003-2006);

- Seat Toledo (1998-2002);

- Leon I /1M/ (2003-2005);

- Skoda Octavia I /A4/ (2000-2010).

In addition to the above, the unit can be found under the hood of the VW Golf 4 Variant, New Beetle Convertible (1Y7), Golf Plus (5M1).

The cylinder block is lightweight, cast from an aluminum alloy. Such a product is considered to be non-repairable, disposable. But in the ICE under consideration, the VAG designers outdid themselves.

The block allows one-time boring of cylinders during its overhaul. And this is already a tangible addition to the total mileage of about 150-200 thousand km.

Aluminum pistons, lightweight, with three rings. Two upper compression, lower oil scraper. Floating fingers. From axial displacement they are fixed with retaining rings.

The crankshaft is mounted on five bearings.

The timing drive is two-belt. The main one drives the intake camshaft from the crankshaft. The secondary connects the intake and exhaust camshafts. The first belt replacement is recommended after 80-90 thousand kilometers. Further, they must be carefully examined every 30 thousand km. The short one needs special attention.

Fuel supply system - injector, distributed injection. It is not demanding on the octane number of the fuel, but on AI-95 gasoline, all the characteristics embedded in the engine are revealed to a greater extent.

In general, the system is not capricious, but there is a need to refuel with clean gasoline, because otherwise the nozzles may become clogged.

The lubrication system is classic, combined. Rotary type oil pump. Driven by the crankshaft. There are no oil nozzles for cooling the piston bottoms.

Electrician. Bosch Motronic ME7.5.10 power system. The high demands of the engine on spark plugs are noted. Original candles (101 000 033 AA) come with three electrodes, so this circumstance should be taken into account when choosing analogues. Incorrect spark plugs increase fuel consumption. The ignition coil is individual for each candle.

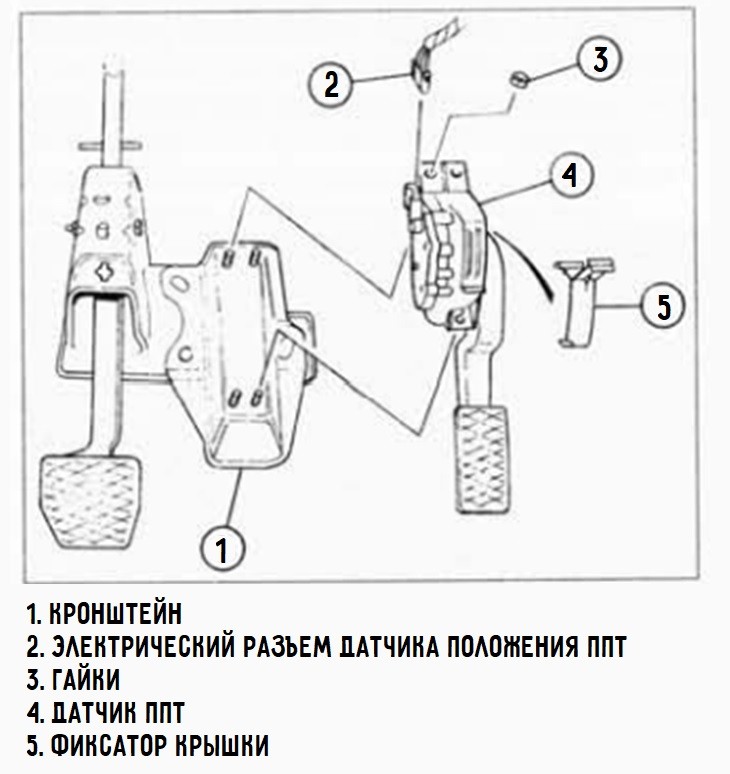

The engine has electronic control of the fuel pedal.

The designers managed to combine all the main parameters in the unit for good driving dynamics.

The graph shows the dependence of the power and torque of the internal combustion engine on the number of revolutions.

Technical specifications

| Manufacturer | Volkswagen Auto Concern |

| Release year | 1996 |

| Volume, cm³ | 1390 |

| Power, hp from | 75 |

| Torque, Nm | 126 |

| Compression ratio | 10.5 |

| Cylinder block | aluminum |

| Number of cylinders | 4 |

| Cylinder head | aluminum |

| Fuel injection order | 1-3-4-2 |

| Cylinder diameter, mm | 76.5 |

| The piston stroke, mm | 75.6 |

| Timing drive | belt (2) |

| Number of valves per cylinder | 4 (DOHC) |

| Turbocharging | no |

| Hydraulic compensators | Yes |

| Camshaft adjuster | no |

| Lubrication system capacity, l | 3.2 |

| Applied oil | 5W-30 |

| Oil consumption (calculated), l / 1000 km | to 0,5 |

| Fuel system | injector, port injection |

| Fuel | gasoline AI-95 |

| Environmental standards | Euro 3 |

| Resource, outside. km | 250 |

| Location | transverse |

| Tuning (potential), l. With | 200* |

* without loss of resource - up to 90 liters. With

Reliability, weaknesses, maintainability

Reliability

It is customary to judge the reliability of any engine by its resource and safety margin. When communicating on forums, car owners speak of BCA as a reliable and unpretentious motor.

So, MistreX (St. Petersburg) writes: “... does not break, does not eat oil and does not eat gasoline. What else does? I have it at Skoda and 200000 hitting everything is super! And traveled in the city, and on the highway to dalnyak».

The bulk of motorists draws attention to the dependence of the resource on timely and high-quality engine maintenance. They argue that with a careful attitude to the car, you can achieve a mileage of at least 400 thousand km, but such indicators require the implementation of all maintenance recommendations.

One of the car owners (Anton) shares: “… I personally drove a 2001 car. with such an engine 500 km without capital and any intervention».

The manufacturer closely monitors its products and immediately takes measures to improve its reliability. So, until 1999, a batch of defective oil scraper rings was supplied.

After such a gap was discovered, the supplier of the rings was changed. The problem with the rings has been closed.

According to the unanimous opinion of car owners, the total resource of a 1.4-liter BCA engine is about 400-450 thousand kilometers before the next overhaul.

The margin of safety of the engine allows you to increase its power to 200 liters. forces. But such tuning will significantly reduce the mileage of the unit. In addition, a very serious alteration of the motor will be required, as a result of which the characteristics of the internal combustion engine will be changed. For example, environmental standards will be reduced to at least Euro 2.

By flashing the ECU, you can increase the power of the unit by 15-20%. This will not affect the resource, but some characteristics will change (the same degree of exhaust gas purification).

Weak spots

Of all the weak points, the most relevant is the oil intake (oil receiver). In most cases, after 100 thousand kilometers, its grid becomes clogged.

The oil pressure in the lubrication system begins to decrease, which gradually leads to oil starvation. Further, the picture becomes quite sad - the camshaft is jammed, the timing belt is broken, the valves are bent, the engine is overhauled.

There are two ways to avoid the described consequences - pouring high-quality oil into the engine and periodically cleaning the oil receiver grid. Troublesome, costly, but much cheaper than a major overhaul of the internal combustion engine.

Of course, other problems occur in the engine, but they are not widespread. In other words, it would be wrong to call them weak points.

For example, sometimes there is an accumulation of oil in the candle wells. The fault is the collapsed sealant between the camshaft support and the cylinder head. Replacing the seal solves the problem.

Often there is an elementary clogging of the nozzles. There are problems with starting the engine, unstable revolutions occur, detonation, misfiring (triple) are possible. The reason lies in the low quality of fuel. Flushing the nozzles eliminates the problem.

Rarely, but there is increased oil consumption. Olegarkh emotionally wrote about such a problem on one of the forums: “... motor 1,4. I ate oil in buckets - dismantled the engine, changed the oil scraper, inserted new rings. That's it, the problem is gone».

Maintainability

One of the tasks that were solved in the design of the internal combustion engine was the possibility of easy recovery even after serious breakdowns of the unit. And she was done. According to the reviews of car owners, the overhaul of the motor does not cause difficulties.

Even the repair of an aluminum cylinder block is available. There will be no problems with the purchase of attachments, as well as with other spare parts. The only thing you need to pay attention to is to exclude the possibility of purchasing counterfeit products. Especially Chinese made.

By the way, a full-fledged high-quality engine repair can only be performed with original spare parts. Analogues, as well as those acquired at disassembly, will not lead to the desired result.

There are many reasons for this, two main ones. Spare parts analogues do not always correspond to the required quality, and parts from dismantling may have a very small residual resource.

Given the simple design of the internal combustion engine, it can also be repaired in a garage. Of course, this requires not only the desire to save on repairs, but also the experience of performing such work, special knowledge, tools and fixtures.

For example, not everyone knows, but the manufacturer prohibits replacing the crankshaft or its liners separately from the cylinder block. This is caused by careful fitting of the shaft and main bearings to the block. Therefore, they change only in the collection.

Volkswagen BCA repair does not raise questions in the service center. Masters are well familiar with the maintenance manuals for such engines.

Watch this video on YouTube

In some cases, it will not be superfluous to consider the option of purchasing a contract engine. The price range is quite wide - from 28 to 80 thousand rubles. It all depends on the configuration, year of manufacture, mileage and a number of other factors.

The Volkswagen BCA engine as a whole turned out to be successful and, in the case of an adequate attitude towards it, pleases its owner with a long resource and economical operation.