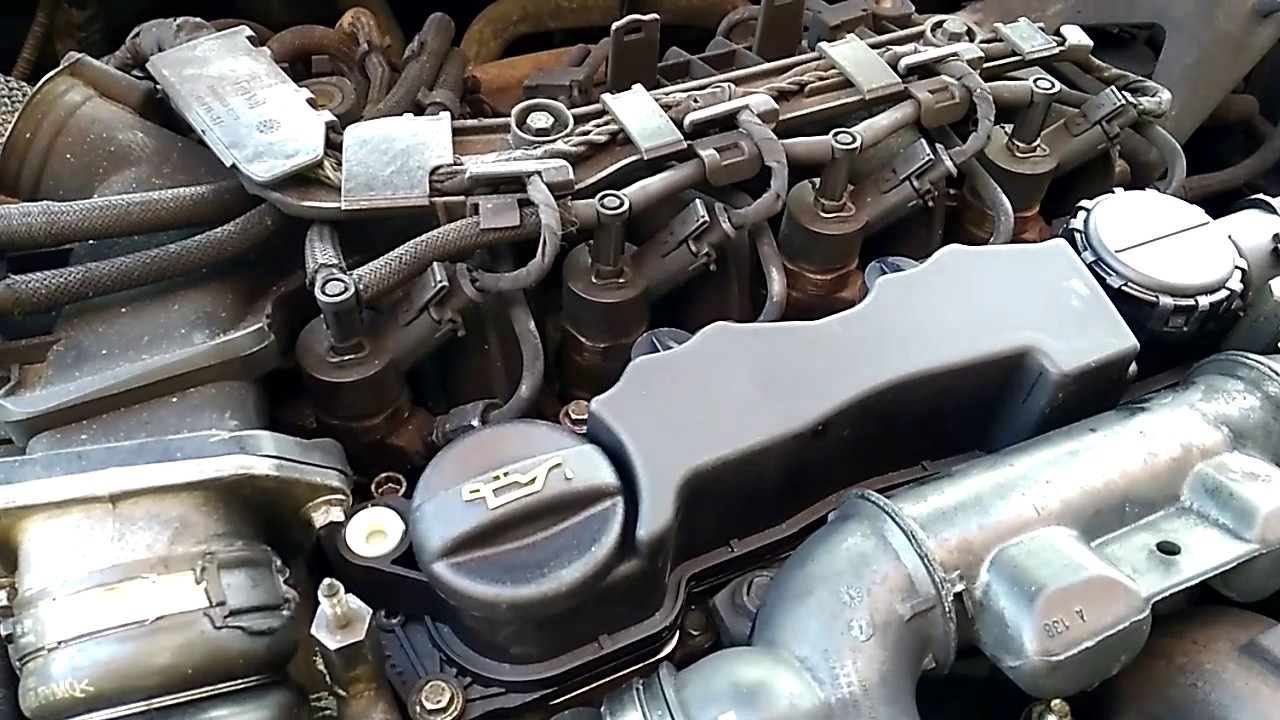

Volvo D4162T engine

Another name for the unit is DV6C 1.6 HDi. It is presented in two versions: 8-valve and 16-valve versions. The first sample came out a little later, while the 16-valve modification debuted in 2002. The D4162T is manufactured by PSA, the world's largest concern producing passenger diesel engines.

Description of the Swedish motor

The engine power system is Common Rail. Management is carried out by means of Bosch equipment (less often Siemens). The system is popular, which reduces repair costs. As for the options with the Siemens ECU, although the injector is considered durable, it is much more expensive to operate. First of all, nozzles cannot be repaired.

Motor in-line layout, four-cylinder. Two camshafts have been used in the cylinder head (the 8-valve version has one). Each cylinder has 4 or 2 valves, which are driven through roller tappets and hydraulic compensators. Fuel supply system - TSI. Turbine - Garrett GT15.

The engine of the main versions develops 110 or 115 hp. s., the compression ratio is 18 or 16 units. The block and head are made of light alloys. Engine emissions comply with Euro 4 and 5 environmental standards.

Basically, the 16-valve version with a toothed timing belt that drives the first camshaft is widespread. The second rotates due to the chain. Every 240 thousand km, the manufacturer indicates to replace the belt, but experienced drivers recommend reducing the interval by half or even three times. As for the chain, it is much more reliable.

The 8-valve unit D4162T is restyled. The working volume is the same as that of the 16-valve engine. But the compression ratio was reduced to 16 units, and the power was reduced by 5 liters. With. higher. Here, one camshaft is used in the cylinder head, there are two valves for each cylinder. The timing drive is carried out by means of a toothed belt. Compliance with environmental standards for this engine is slightly higher.

| 16-valve version of Volvo 1.6D (D4162T) / 110 hp aka PSA 1,6 HDI (DV6TED4) | 8-valve version of Volvo 1.6 D2 (D4162T) / 115 hp aka PSA (DV6C) | |

| Engine design | 4-cylinder in-line | 4-cylinder in-line |

| Working volume | 1560 sm3 | 1560 sm3 |

| Power | 80 kW / 110 HP at 4000 rpm | 85 kW / 115 HP at 3600 rpm |

| Torque | 240 Nm (up to 260 Nm in Overboost mode) at 1750 rpm | 270 Nm (up to 285 Nm in Overboost mode) at 1750 rpm |

| Implementation range 80% of maximum torque | 1300 - 4000 rpm | 1300 - 3600 rpm |

| Gas distribution system | 2 camshafts in the cylinder head | 1 camshaft in the cylinder head |

| Bore | 75.0 mm | 75.0 mm |

| Piston stroke | 88.3 mm | 88.3 mm |

| Compression ratio | 12.01.1900 | 16 units |

| Number of valves per cylinder | 4 valves per cylinder | 2 valves per cylinder |

| Timing drive | combined - toothed belt and chain | toothed belt |

| Valve drive | roller tappets and hydraulic lifters | roller tappets and hydraulic lifters |

| Injection system | Direct Common Rail | Direct Common Rail |

| Injection control system | Bosch, Siemens | Bosch, Siemens |

| Injection pressure (maximum) | 1600 Bar | 2800 Bar |

| Turbocharger | Garrett GT15 Variable Turbo Geometry | Garrett GT15 Variable Turbo Geometry |

| Boost pressure (g) | 1.25 Bar | 1.25 Bar |

| Material of cylinder block and cylinder head | light alloy | light alloy |

| Environmental Compliance | EuroIV | Euro V. |

| Recommended diesel fuel (DF) | Grade F type II GOST R 52368-2005 (EH 590:2004) | Grade F type II GOST R 52368-2005 (EH 590:2004) |

Modification D4164T

As mentioned, D4162T exists in several versions. The hardware configuration may also differ. For example, there may be a different type of turbine, flywheel. There are versions with a particulate filter, there are without it. Low-power versions have the simplest set of equipment.

The 16-valve DV6TED4 engine is one of the best engine modifications. Installed on Volvo V50 2004-2011 release. Also found under the hoods of Peugeot, Citroen, some BMW models, Ford and Suzuki. The following characteristics stand out from the features:

- full adaptation to the Russian climate - the presence of a thermoelement in the filter for use in severe frosts;

- transverse arrangement;

- availability of equipment for calculating and regulating fuel refueling at gas stations;

- variable nozzle turbine turbo system.

Note that it is this motor that the second most important German concern BMW uses for its new Mini Coopers. BMW itself is not involved in the production, which once again proves the impeccability of the DV PSA series diesels. Recall that PSA and the Bavarian concern began their cooperation earlier, with the production of gasoline engines of the EP series. These power plants were placed under the hoods of the Peugeot 308. As for the diesel version of the Peugeot 308 Hdi, equipped with the D4164T, it broke two world records for fuel economy at once.

| Lubrication system | |

| Oil pump | rotary type, located in the oil pan behind the crankshaft on the side of the timing belt drive |

| Oil pressure control valve | built into the oil pump housing, opens when pressurized oil about 800 kPa |

| The oil filter | cartridge type, with a channel, opening at dismantling |

| Oil cooler | is a plate heat exchanger connected to the system coolant, through the oil cooler coolant fed further into the body thermostat |

| Oil pressure switch | located to the right of the oil cooler, pressure switch contacts oils open at pressure over 50 kPa and oil pressure light goes out |

| Piston cooling nozzles | are cooled by oil supplied from below through nozzles designed for this purpose, which are mounted in the cylinder block, are connected to lubrication circuit in engine |

| Fuel intake and exhaust systems | |

| bypass damper | intended for the charge cooler air, setting produced by a stepper motor cleaning the particle filter |

| Air cooler bypass | provides a direct connection from the turbocharger outlet to the intake flapper, thereby bypassing the charge air cooler |

| Control element | engine control module (ECM) using pulse-width modulated signals |

| Exhaust gas recirculation system - EGR | |

| Stepper motor in the EGR system | fixed in the cylinder block on the exhaust side and regulates the amount of exhaust gas returned |

| Control method | using pulse-width modulated signals |

| Catalytic converter | reduces the content of CO and HC in emissions into the atmosphere, placement directly after turbocharger |

| Turbo system | |

| Turbocharger | has a turbine with variable inlet geometry and a charge air cooler |

| Turbine control valve | performs stepless adjustment of the vacuum in the pressure chamber, which controls the turbine guide vanes (Variable Nozzle Turbine, VNT) |

| Cooling system | |

| Thermostat | mounted on the cylinder head from the side of the gearbox, plastic housing, non-separable |

| Engine coolant temperature sensor | located in the thermostat housing and fixed with a clamp; in addition to the thermostat, a bypass valve is also installed there |

| Coolant pump | mounted on the belt drive side of the timing mechanism and driven by a toothed belt |

| Supply system | |

| Fuel metering valve | installed in the intake duct between the fuel priming pump and the high pressure pump, doses the amount of fuel that to be fed into the camera high pressure, taking into account operating conditions, has protection in case collision |

| fuel distribution line | fixed directly to the cylinder block with 2 mounting screws, made of forged steel |

| Pressure pipelines | connect the fuel distribution line to the high pressure pump and injectors |

| Nozzles | actuated directly by the engine control module (ECM), installed in holders, which are fixed 2 nuts each in the valve box |

| Drain fuel lines | fixed on top of the nozzles with clamps |

| Fuel filter | with a water separator, mounted on a holder directly in the cylinder head and equipped with an electric fuel preheater, has protection in case collision |

Repairs and problems

The "sores" of this unit are known to all experienced owners.

- Siemens injection system. Today, the repair of injectors under this control in Russia is practically not feasible. There are only a few companies that specialize in this type of nozzle. They have professional test benches. Another difficulty lies in the transportation of injection elements of this type - they should only be transported in an upright position, otherwise they will be damaged.

- Difficult start diesel. As a rule, this is associated with glow plugs, which are used as fuel reheating. There are no other elements for this, because this is the only way the motor works stably.

- The problem with the plastic flaps on the intake manifold. They are designed to restrict air into the intercooler when the engine is still cold or at low temperatures. The engine heats up faster this way, but these useful dampers quickly fail - they cut off the gear teeth.

- The DPF filter will soon become clogged.

| Fin | The 2.0D 100kW engine is a Peugeot/Citroen product that has been used in Volvos such as S40II, V50, C30, and V70III S80II. Engines are divided into two types - from 2004 to ~ 2006 production with EURO3 environmental requirements, as well as from 2006 with EURO4. The last engine was used with a particulate filter (in other words - DPF or FAP). All engines are filled with synthetic oil with recommended 5W30 viscosity characteristics and Citroen / Peugeot approval. For a run of 20000 km. Whether the engines installed in Volvo cars differ from those mounted in Ford / Peugeot / Citroen cars - I do not know, so we will only talk about Volvo and their most common problems. |

| Norik | As described above, there are two types of engines, Euro 3 and Euro 4. Note: Some engines since 2006 have come with Euro 3 requirements, but technically they are Euro4. Problems: 1) SIEMENS injectors: the car shakes after starting, but after starting it works normally after some time. Unfortunately, it is currently impossible to repair SIEMENS; only a few companies with serious test benches for Siemens can check it. Important: transportation and storage of this type of injectors is only possible in a VERTICAL position, otherwise they will fail. 2) Poor starting: Caused by several reasons, and not only the spark plugs are to blame. |

| Master 100 | Yes, there are several such things: Worn injector needle (dispenser), resulting in fuel backflow and the nozzle does not provide sufficient fuel pressure. Possible consequences are not only poor starting, but also an increase in the temperature of the combustion chamber, the pistons melt, and the combustion chamber is damaged due to a lean mixture. Nozzle nozzle deformation. This is a common problem for Euro 3 and Euro 4. From a mixture that is too lean due to the fact that the dispenser is deformed, at elevated temperatures the tips may melt, the fuel supply holes become larger, the fuel is supplied incorrectly, is poorly atomized / in the wrong direction, the effect is an engine defect or - if the injector starts to flow because the cylinder full of unburnt fuel. Sometimes the oil level increases as fuel flows through the rings into the crankcase. Compressed connecting rods. Determining the problem is not easy, but it is possible. Connecting rods for these engines are a hot commodity in landfills. Especially for upgraded engines with EURO4, but also sometimes happens with EURO3. There are two reasons: the mixture is too rich, resulting in a water hammer in the cylinder and the connecting rod “compresses”. As a rule, 1 mm is enough for the engine to start poorly, vibrate, and so on. You can establish a defect like this: we measure the compression in all cylinders - it will probably be normal, but where there is a defect, the compression takes much longer to pump up compared to other cylinders, because the volume of the combustion chamber is larger. Maintenance is as follows: replacing a connecting rod, or several. Other factors, often with EURO4 - the DPF filter gets clogged, the exhaust flow rate deteriorates, the pressure in the combustion chamber increases - damage to the connecting rods/motor/turbine. The cams are torn off the camshaft seats. This can also happen for the reasons mentioned above. When the cams break, the combustion phases change, the possible consequences are repairing the engine head, replacing the camshaft(s), or replacing the engine - this is in a worse scenario. |

| Gavroche | There is no information on 1.6d yet, we encounter little because we advise you not to take them. I write myself, from practice, but in practice there are very few on 1.6. |

| Gek70 | And the nozzles of the nozzles are deformed and the needles wear out at what mileage (from practice)? Also, what about removing the catalyst? |

| Fin | I can not answer about runs and statistics on kilometers. poured kaku and death to the nozzle. some who did capital at 120 |

| Pudik | for two years of owning a 407 with this engine (not sawn), I can confirm the wear of the intake manifold gears, well, I changed the candles, but I didn’t notice anything on the engine. fap cut out before problems appeared. There were no problems with siemens on cranking and in cold weather. Reviews of repairmen about these engines are positive (unlike 1,6) |

| Gek70 | Something withered topic. According to the forum, as I understand it, there are no problems with the engine, except for the EGR valve and the generator. Then what about adding two-stroke oil to the fuel? Some recommend, because. fuel is “dry”, others are categorically not. The person who brought the car to me (he lives in Germany) recommended me to refuel exclusively at gas stations without any additives and not to bathe. And will the removal of the catalyst (not the FAP) increase the life of the turbine? |

| Sergiy | the manufacturer does not say anything about the oil in the fuel |

| Gek70 | I know. But he talks about biofuels. Interesting, right? |

| bison | And the engine is 2.4 bin. 170 l.? |

| Gelaev | If you want your fuel system to die for a long time - pour two-stroke oil, anti-ice and all sorts of other additives, and be sure to listen to all sorts of Vasya, Pet and other specialists. When the fuel system is in order, nothing needs to be poured. fill up at proven gas stations and you will be happy. Every winter I observe the same picture - in the mornings, diesel-economists (and not only) arrange dances with tambourines around their buckets, but during joint gatherings with foam at the mouth, proving that there is nothing better than diesel. With current fuel prices and the cost of repairing modern diesel engines, can it be easier to buy gasoline? |

| Gek70 | Confirmed. Diesel went by accident. There were no other options. But, I'm used to it. And I will not say that 2.0D is very economical. But it pulls hard, which in itself is nice. Yes, and it starts at -29 (there was no lower) without dancing. It is only necessary not to turn the car into trash. And the repair of a gasoline engine will also cost a pretty penny. Still, not the trade wind B3 (it was so cheap and reliable, but the view and comfort are not the same). |