Volvo D5244T engine

One of the best 5-cylinder turbodiesels from the Swedish company Volvo. Designed for use in cars of our own production. The working volume is 2,4 liters, the compression ratio depends on the specific modification.

About motors D5 and D3

It is noteworthy that only 5-cylinder diesel units are a unique development of the Swedish concern. Other engines, such as the 4-cylinder D2 and D4, are borrowed from PSA. For this reason, the latter are, in fact, much more common under the 1.6 HDi and 2.0 HDi brands.

The working volume of diesel "fives" of the D5 family is 2 and 2,4 liters. The first group is represented by the D5204T motor, the second - by the described D5244T. However, the name D5 is inherent only in strong versions of this family, the power of which exceeds 200 hp. With. The remaining engines are usually referred to in the commercial sphere as D3 or 2.4 D.

The arrival of the D3 format was generally the main news. In addition to the fact that the piston stroke was reduced from 93,15 to 77 mm with the cylinder diameter left as before, the working volume of the unit was reduced - from 2,4 to 2,0 liters.

D3 was offered in several versions:

- 136 l. With.;

- 150 l. With.;

- 163 l. With.;

- 177 l. from.

These modifications always came with a single turbocharger. But some 2.4 D, on the contrary, received a double turbine. These versions easily provided power above 200 hp. With. Another distinctive feature of the D3 engines is that their injection system was considered unrepairable, as it was equipped with nozzles with a piezo effect. In addition, the cylinder head did not have swirl flaps.

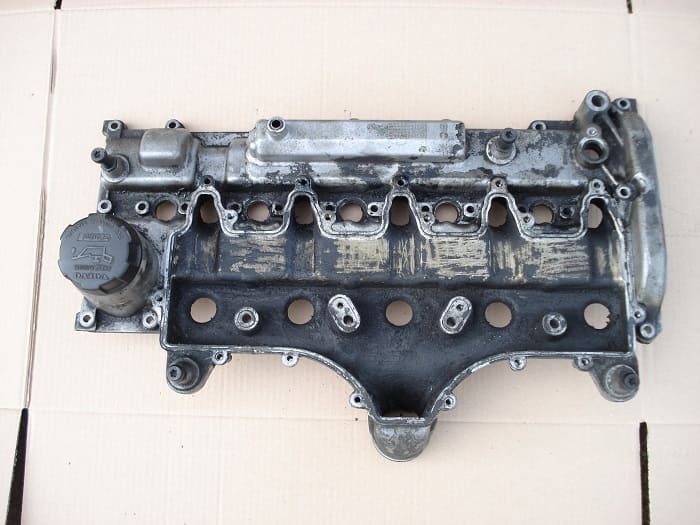

Design Features D5244T

The cylinder block and engine head are made of lightweight materials. There are 4 valves per cylinder. Thus, this is a 20-valve unit with a double overhead camshaft system. Injection system - Common Rail 2, the presence of an EGR valve on many versions.

The use of the new Common Rail in modern diesel engines has somewhat frightened users. However, Bosch fuel management has kept all fears to a minimum. The system is reliable, despite the need to replace the nozzles after the end of their service life. In some cases, even their repair is possible.

Modifications

The D5244T has many modifications. In addition, a series of these motors has been developed in several generations. In 2001, the first came out, then in 2005 - the second, with a reduced compression ratio and a VNT turbine. In 2009, the engine received other changes aimed at modernizing the injection and turbocharging systems. In particular, new nozzles were introduced - with a piezo effect.

In more detail, the stages of development of emissions from these units can be represented as follows:

- from 2001 to 2005 - the emission standard at the Euro-3 level;

- from 2005 to 2010 - Euro-4;

- after 2010 - Euro-5;

- in 2015 there are new Drive-E.

The Euro 5 5-cylinder D3 was designated D5244T or D5244T2. One gave out 163, the other - 130 hp. With. The compression ratio was 18 units, the particulate filter was initially absent. The injection system was controlled by Bosch 15. Motors were installed on the S60 / S80 and the XC90 SUV.

After the introduction of Euro-4 since 2005, the piston stroke was reduced to 93,15 mm, and the working volume was increased by only 1 cm3. Of course, for the buyer, these data had practically no meaning, because power was much more important. It increased to 185 horses.

The control system remained the same from Bosch, but with a more sophisticated version of the EDC 16. The noise level of the diesel unit dropped to almost zero (it was already quiet from the start), due to a decrease in the compression ratio. On the downside, a maintenance-free particulate filter has been added. Units with Euro-4 were designated T4 / T5 / T6 and T7.

The main modifications of the D5244T are considered to be these:

- D5244T10 - 205 hp engine, CO2139-194 g/km;

- D5244T13 - 180-horsepower unit, installed on the C30 and S40;

- D5244T15 - this engine is capable of developing 215-230 hp. with., installed under the hoods of the S60 and V60;

- D5244T17 - 163-horsepower engine with a compression ratio of 16,5 units, installed only on the V60 station wagon;

- D5244T18 - 200-horsepower version with 420 Nm of torque, installed on the XC90 SUV;

- D5244T21 - develops 190-220 hp. with., installed on sedans and station wagons V60;

- D5244T4 - 185-horsepower engine with a compression ratio of 17,3 units, installed on the S60, S80, XC90;

- D5244T5 - unit for 130-163 liters. with., installed on the S60 and S80 sedans;

- D5244T8 - the engine develops 180 hp. With. at 4000 rpm, installed on C30 hatchback and S sedan

| D5244T | D5244T2 | D5244T4 | D5244T5 | |

| Maximum power | 163 hp (120 kW) at 4000 rpm | 130 hp (96 kW) at 4000 rpm | 185 hp (136 kW) at 4000 rpm | 163 h.p. (120 kW) at 4000 rpm |

| Torque | 340 Nm (251 lb-ft) at 1750–2750 rpm | 280 Nm (207 lb-ft) at 1750-3000 rpm | 400 Nm (295 lb-ft) @ 2000-2750 rpm | 340 Nm (251 lb-ft) at 1750-2 rpm |

| Maximum RPM | 4600 rpm | 4600 rpm | 4600 rpm | 4600 rpm |

| Bore and stroke | 81 mm × 93,2 mm (3,19 in × 3,67 in) | 81 mm × 93,2 mm (3,19 in × 3,67 in) | 81 mm × 93,2 mm (3,19 in × 3,67 in) | 81 mm × 93,2 mm (3,19 in × 3,67 in) |

| Working volume | 2401 cu. cm (146,5 cu in) | 2401 cu. cm (146,5 cu in) | 2401 cu. cm (146,5 cu in) | 2401 cu. cm (146,5 cu in) |

| Compression ratio | 18,0: 1 | 18,0: 1 | 18,0: 1 | 18,0: 1 |

| Type of supercharging | BHT | BHT | BHT | BHT |

| D5244T7 | D5244T8 | D5244T13 | D5244T18 | |

| Maximum power | 126 hp (93 kW) at 4000 rpm | 180 h.p. (132 kW) | 180 h.p. (132 kW) | 200 hp (147 kW) at 3900 rpm |

| Torque | 300 Nm (221 lb-ft) at 1750–2750 rpm | 350 Nm (258 lb-ft) @ 1750-3250 rpm | 400 Nm (295 lb-ft) @ 2000-2750 rpm | 420 Nm (310 lb-ft) @ 1900-2800 rpm |

| Maximum RPM | 5000 rpm | 5000 rpm | 5000 rpm | 5000 rpm |

| Bore and stroke | 81 mm × 93,2 mm (3,19 in × 3,67 in) | 81 mm × 93,2 mm (3,19 in × 3,67 in) | 81 mm × 93,2 mm (3,19 in × 3,67 in) | 81 mm × 93,2 mm (3,19 in × 3,67 in) |

| Working volume | 2401 cu. cm (146,5 cu in) | 2401 cu. cm (146,5 cu in) | 2401 cu. cm (146,5 cu in) | 2401 cu. cm (146,5 cu in) |

| Compression ratio | 17,3: 1 | 17,3: 1 | 17,3: 1 | 17,3: 1 |

| Type of supercharging | BHT | BHT | BHT | BHT |

| D5244T10 | D5244T11 | D5244T14 | D5244T15 | |

| Maximum power | 205 HP (151 kW) at 4000 rpm | 215 hp (158 kW) at 4000 rpm | 175 hp (129 kW) at 3000-4000 rpm | 215 hp (158 kW) at 4000 rpm |

| Torque | 420 Nm (310 lb-ft) @ 1500-3250 rpm | 420 Nm (310 lb-ft) @ 1500-3250 rpm | 420 Nm (310 lb-ft) @ 1500-2750 rpm | 440 Nm (325 lb-ft) at 1500-3000 rpm |

| Maximum RPM | 5200 rpm | 5200 rpm | 5000 rpm | 5200 rpm |

| Bore and stroke | 81 mm × 93,15 mm (3,19 in × 3,67 in) | 81 mm × 93,15 mm (3,19 in × 3,67 in) | 81 mm × 93,15 mm (3,19 in × 3,67 in) | 81 mm × 93,15 mm (3,19 in × 3,67 in) |

| Working volume | 2400 cu. cm (150 cu in) | 2400 cu. cm (150 cu in) | 2400 cu. cm (150 cu in) | 2400 cu. cm (150 cu in) |

| Compression ratio | 16,5: 1 | 16,5: 1 | 16,5: 1 | 16,5: 1 |

| Type of supercharging | Two stage | Two stage | BHT | Two stage |

Advantages

Many experts agree with the opinion that the first versions of this engine were not so capricious and relatively reliable. These motors did not have flaps in the intake manifold, there was no particulate filter. Electronics were also kept to a minimum.

With the introduction of Euro-4 standards, turbocharging management has improved. In particular, we are talking about the accuracy of the settings. The vacuum drive, which was considered less complex and vulnerable, but was archaic and too simple, was replaced by an advanced electrical mechanism.

2010 was marked by the launch of the Euro-5 standard. The compression ratio again had to be reduced to 16,5 units. But the most significant change occurred in the cylinder head. Although the gas distribution scheme was left the same - 20 valves and two camshafts, the air supply became different. Now the dampers were installed directly in front of one of the intake valves in the head. And each cylinder got its own damper. The latter, like the rods, were made of plastic, which made sense. As you know, metal shutters often destroyed cylinders when they broke and got inside the engine.

Disadvantages

Consider them in more detail.

- With the transition to Euro-4, an intercooler - a compressed air cooler - got into the risk zone. He could not withstand long work, as a rule, he cracked due to excessive loads. The main sign of its malfunction was considered an oil leak and the engine went into emergency mode. Another weak point in the boost system of the D5 engines was the cooler pipe.

- With the transition to Euro-5, the damper drive became vulnerable. Due to the high loads inside the mechanism, a backlash was created over time, causing a mismatch. The motor immediately reacted to this by stopping. The drive could not be replaced separately, it was necessary to install it in assembly with dampers.

- The fuel pressure regulator on the latest modifications could cause poor starting, unstable engine operation at low revs.

- Hydraulic lifters are too sensitive to oil quality. After the 300th run, there are cases when they failed and caused a characteristic tapping. In the future, this problem could cause the destruction of seats in the cylinder head.

- Often the cylinder head gasket pierced, due to which gases leaked into the cooling system, and the refrigerant penetrated into the cylinders.

- In 2007, after another restyling, the drive of additional equipment receives 3 belts. The alternator belt and the tension roller turned out to be extremely unsuccessful, in which the bearing could unexpectedly break. The last malfunction easily caused the following: the roller warped, flew off at high engine speeds and fell under the cover of the gas distribution mechanism. This caused the timing belt to jump, followed by a meeting of the valves with the pistons.

Volvo's "five" as a whole is reliable and durable, if you properly care for it. After the 150th run of the car, it is necessary to periodically monitor the timing belt, update the pump and the belt of auxiliary attachments. Fill in oil on time, no later than the 10th run, preferably 0W-30, ACEA A5 / B5.

| Karelian | Machine 2007, injectors cost 30777526 The problem is that the D5244T5 engine is pounding on the twentieth. And this is not a failure of any one cylinder, but the overall operation of the motor. There are no errors! Very smelly exhaust. The nozzles were checked on the stand, two were repaired according to the results. There is no result - nothing has changed. The USR was not physically jammed, but a branch pipe was thrown back from the collector in order to exclude air from the exhaust gas. The operation of the motor has not changed. I did not see any deviations in the parameters - the fuel pressure corresponds to the specified one. Tell me where else to dig? Yes, another observation - if you remove the connector from the fuel pressure sensor, then the engine will stabilize, and it starts to work smoothly! |

| Leon Rus | Write the numbers of the injectors in Bosch, and the parameters to the studio. I would like to know the whole history. How did it all start? |

| Karelian | BOSCH 0445110298 Hardly anyone can say how it started! We work with car dealerships, they don’t ask when purchasing))) The mileage of the car is solid for this year, more than 500000 km! And apparently they tried to deal with the problem - wires were thrown from the pressure sensor to the ECU - apparently they saw the same thing, that when the sensor is turned off, the work is evened out. By the way, we threw the sensor from the donor. What parameters are of interest? The fuel pressure is correct. In fact, there is nothing to check, alas. The corrections seem to be outrageous!? |

| Tubabu | So start with a compression check, no need to rely on the scanner readings. 500t.km. no longer a small mileage, and even unscrewed the most |

| Karelian | Asked the mechanics to take measurements. But how then to explain that when the pressure sensor is turned off, the operation of the motor is leveled? And at RPM the motor runs smoothly. I will insist, of course, on the measurement, any information can be useful ... |

| Melik | On the Volvo D5 engine for Euro-3, nozzles are installed with an indication of their class. The class characterizes the injection parameters of injectors and their performance. There are 1st, 2nd, 3rd and, rarely, 4th grades. The class is indicated on the injector separately or as the last digit in the injector number. The “classiness” of injectors must be taken into account when replacing them with new and used ones. The entire set of nozzles must be of the same class. You can install the entire set of injectors of a different class, but this change must be registered through a diagnostic scanner. It is also possible to install one or two nozzles of the 4th class, which is considered a repair one, without registration. It will not work to use class 1, 2 and 3 nozzles on one motor - the engine will work ugly. But on D5 engines under Euro-4 since May 2006, when installing injectors, you need to register IMA codes that characterize the individual performance of the injector. |

| Marik | They said they checked the injectors. |

| DimDiesel | When the chip is disconnected from the sensor, the unit enters emergency mode at a higher pressure in the rail than xx, and the injection is higher, respectively. At rpm, the pressure also rises and the injection increases. All further graters without measuring compression are useless (what to guess) ... |

| Melik | It's not the compression that's the problem, it's the injectors. Most likely the check and repair is not entirely correct. This nozzle is specific for repair and is not always within the power of craftsmen without experience with it. |

| Leon Rus | Yeah... the nozzle is interesting. Actually, it's strange that the machine works without a pressure sensor. Look at the wiring, maybe “chip tuning” is hanging. |

| Tubabu | I don't understand what's so special about injectors. Here the hydraulic compensators on these motors run out quickly, far to 500 |

| Karelian | Here you have to rely on the professionalism of the performer. Forces were given to St. Petersburg, the person seems to be seriously dealing with this issue. What is the difficulty of working with these forces? I traced the DD wiring to the ECU - there is nothing abnormal. |

| Saab | There is nothing special about it. Have you been given test plans for checking injectors? |