VR6 engine - the most important information about the unit from Volkswagen

Content

The VR6 engine was developed by Volkswagen. The first installation was introduced in 1991. As a curiosity, we can say that VW was also involved in the production of the VR5 motor, the design of which was based on the VR6 unit. More information about installing VR6 can be found in our article.

Basic information about the Volkswagen unit

At the very beginning, you can "decipher" the abbreviation VR6. The name comes from an abbreviation created by a German manufacturer. The letter "V" refers to the "V-motor", and the letter "r" to the word "Reihenmotor", which is translated as a direct, in-line engine.

The VR6 models used a common head for the two cylinder banks. The unit is also equipped with two camshafts. They are present both in the engine version with two and four valves per cylinder. Thus, the design of the unit is simplified in maintenance, which reduces its operating costs. The VR6 engine is still in production. Models equipped with this engine include:

- Volkswagen Golf MK3, MK4 and MK5 Passat B3, B4, B6, B7 and NMS, Atlas, Talagon, Vento, Jetta Mk3 and MK4, Sharan, Transporter, Bora, New Beetle RSi, Phateon, Touareg, EOS, CC;

- Audi: A3 (8P), TT Mk 1 and Mk2, Q7 (4L);

- Location: Alhambra and Leon;

- Porsche: Cayenne E1 and E2;

- Skoda: the superb 3T.

12 cylinder version

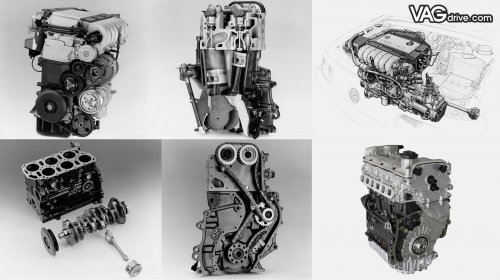

Units originally produced had two valves per cylinder, for a total of twelve valves. They also used a single camshaft for the intake and exhaust valves in each block. In this case, no rocker arms were used either.

The first version of the VR6 had a displacement of 90,3 millimeters for a total displacement of 2,8 liters. An ABV version was also created, which was distributed in some European countries and had a volume of 2,9 liters. It is also worth mentioning that due to the two rows of pistons and cylinders with a common head and the piston head gasket or its upper surface is inclined.

For the 12-cylinder version, a V angle of 15° was chosen. The compression ratio was 10:1. The crankshaft was located on seven main bearings, and the necks were offset from each other by 22 °. This made it possible to shift the arrangement of the cylinders, as well as to use a gap of 120 ° between successive cylinders. The Bosch Motronic unit control system was also used.

24 cylinder version

In 1999 a 24 valve version was introduced. It has a single camshaft that controls the intake valves of both rows. The other, on the other hand, controls the exhaust valves of both rows. This is done using valve levers. This design feature is similar to the DOHC double overhead camshaft. In this setup, one camshaft controls the intake valves and the other controls the exhaust valves.

W-motors - how do they relate to the VR model?

A rather interesting solution created by the Volkswagen concern was the design of units with the designation W. The design was based on the connection of two BP units on one crankshaft - at an angle of 72 °. The first of these engines was the W12. It was produced in 2001.

The successor, the W16, was installed in the Bugatti Veyron in 2005. The unit has been designed with a 90° angle between two VR8 units and is equipped with four turbochargers.

What is the difference between a traditional V6 engine and a VR6 engine?

The difference is that it uses a narrow angle of 15° between the two cylinder banks. This makes the VR6 engine wider than the V6. For this reason, the VR unit is easier to fit into the engine compartment, which was originally designed for a four-cylinder unit. The VR6 motor is designed to be mounted transversely in front wheel drive vehicles.

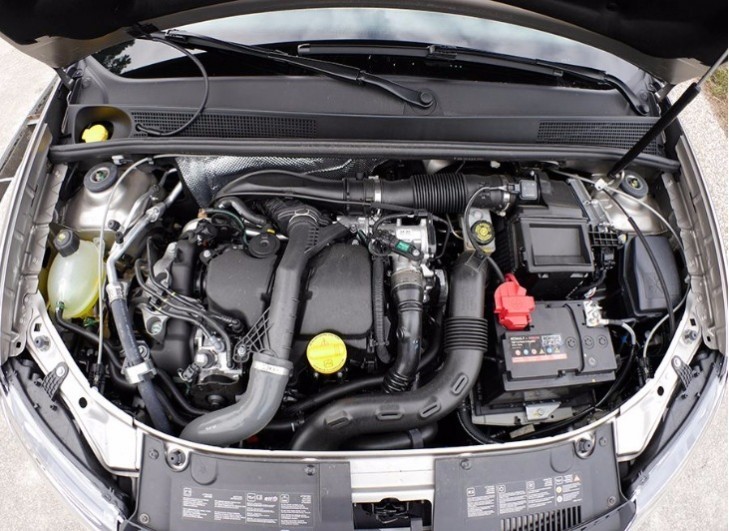

A photo. View: A. Weber (Andy-Corrado/corradofreunde.de) from Wikipedia