BMW N73B60, N74B60, N74B66 engines

Content

The BMW N73B60, N74B60, N74B66 engines are advanced models of popular engines for the BMW 7 series in the back of the E65, E66, E67 and E68, as well as Rolls-Royce.

Each engine is a subsequent generation of the old model: all motors operate on a similar principle and have approximate technical characteristics, differing only in the well-thought-out design.

Development and production of BMW N73B60, N74B60, N74B66 engines: how was it?

The production of multi-series engines was compatible with the production of the 7 series by BMW. The development of the first BMW N73B60 series began in early 2000, and the engine itself entered the assembly line from 2004 and was produced until 2009, after which it was replaced by the next generation N74B60 and N74B66.

The production of multi-series engines was compatible with the production of the 7 series by BMW. The development of the first BMW N73B60 series began in early 2000, and the engine itself entered the assembly line from 2004 and was produced until 2009, after which it was replaced by the next generation N74B60 and N74B66.

Currently, the production of engines continues and in the secondary car market you can freely find original components and analogues of spare parts. Despite the high power, the engine is fitted with replica dealer parts that do not shorten the service life or power - the BMW N73B60, N74B60, N74B66 models are a good investment for power lovers.

This is interesting! Each engine in the series was developed according to its own project, however, components from the previous generation were used for production. This step made it possible to unify the design, facilitating the manufacturing stage and eliminating all the weaknesses of the old models.

Specifications: what is similar in models

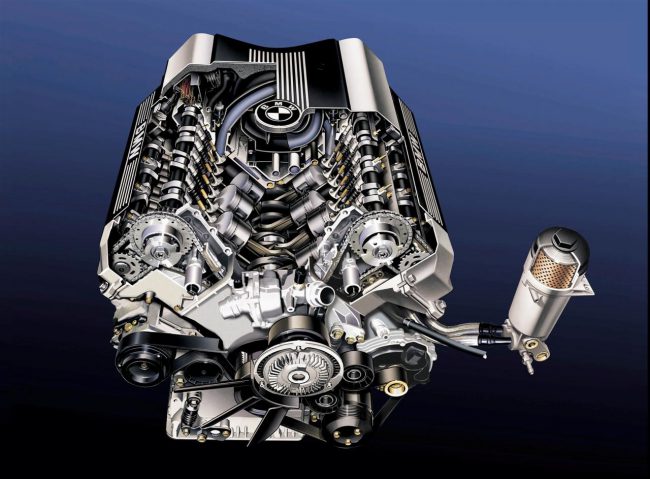

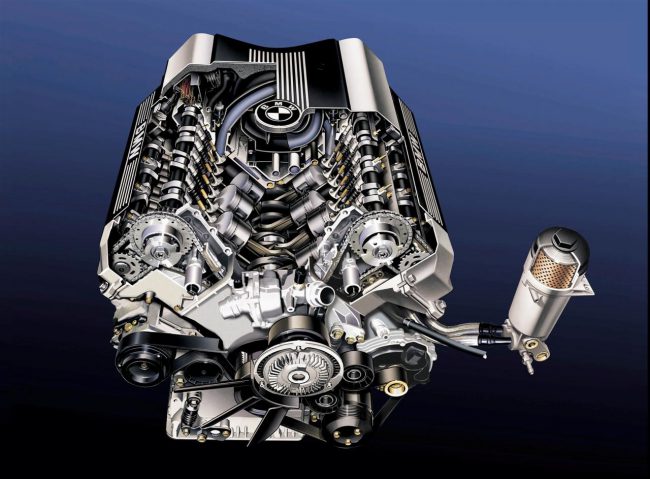

The entire series of engines is a 12-cylinder engine designed on a V-shaped architecture.  All components are made of aluminum, and body parts and CPG are compatible with any generation of the engine, which increased the reparability and reduced the cost of parts production. Also, from the common features in the BMW N73B60, N74B60, N74B66 engines, it should be noted:

All components are made of aluminum, and body parts and CPG are compatible with any generation of the engine, which increased the reparability and reduced the cost of parts production. Also, from the common features in the BMW N73B60, N74B60, N74B66 engines, it should be noted:

- High precision fuel injection system;

- An independent system of piezoelectric elements that provide ignition;

- A pair of air heaters operating according to the principle of indirect through blowing with indirect cooling;

- Vacuum system with two-stage vacuum pump;

- Double-VANOS system.

Each of the generations of the series was equipped with a distinctive oil supply and crankcase ventilation system, and also had an upgraded camshaft and toothed roller chain design. Also, the entire line of electronic equipment responsible for the uniformity of fuel supply and ignition frequency was subjected to refinement.

| The order of the cylinders | 1-7-5-11-3-9-6-12-2-8-4-10 |

| Cylinder diameter / piston stroke, mm | 89,0/80,0 |

| Distance between cylinders, mm | 98.0 |

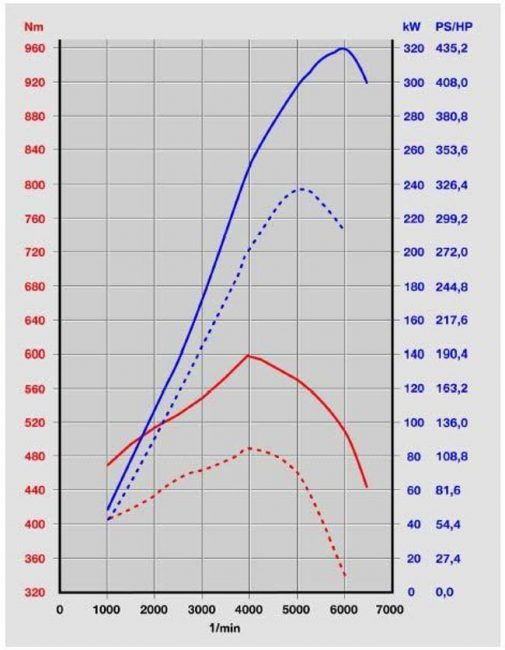

| Power, hp (kW)/rpm | 544/5250 |

| Torque, Nm / rpm | 750/1500-5000 |

| Liter power, hp (kW)/liter | 91,09 (66,98) |

| Compression ratio | 10.0 |

| Engine management system | 2 x MSD87-12 |

| Approximate weight, kg | 150 |

Each of the engines had its own automatic transmission, however, on the budget trim levels of the Germans, the 7 series was equipped with a regular ZF 8HP. The VIN number of the factory engine was stamped on the top cover of the motor between the air intakes of the superchargers.

Weaknesses of the series: where to expect a breakdown

Production from scratch of each engine made it possible to reduce the number of vulnerabilities in the designs of each motor, however, despite the thoughtfulness of the technical architecture, gaps were revealed on the motors during intensive operation. The main disadvantages of the BMW N73B60, N74B60, N74B66 observed before the guaranteed resource were:

- Floating idle speed - due to the peculiarities of the operation of the Valvetronic system, when the engine reached the operating temperature at idle, the vibration load increased, which led to strong shocks that interfered with a stable supply of fuel. This malfunction is a factory defect and was eliminated only with the production of a new unit architecture;

- Complex timing design - the motor belt is susceptible to high thermal effects, which requires regular maintenance. It is recommended to change the components of the timing unit every 80-100 km of run;

- Motor decompression - the situation is caused by a violation of the tightness of the intake tract, which is corrected by the timely replacement of o-rings and sealant;

- Cylinder block failure - the entire engine system operates on the basis of two control units, and if one of them breaks down, a number of cylinders are turned off.

The design of the BMW N73B60, N74B60, N74B66 engines was characterized by many moving parts that increased the overall temperature of the engine. In order to avoid overheating of the engine, it is recommended to completely change the coolant every 2 years with a mandatory flushing of the system.

Possibility of tuning

In view of the complex structural base, outside interference with the components of the motor is prohibited by the manufacturer - most of the modified elements adversely affect the operational life of the engine and cause expensive repairs.

In view of the complex structural base, outside interference with the components of the motor is prohibited by the manufacturer - most of the modified elements adversely affect the operational life of the engine and cause expensive repairs.

A reasonable step to increase engine performance is only chip tuning: flashing electrical equipment allows you to stabilize the fuel supply by setting the engine to maximum speed or traction. Electronic firmware allows you to increase the engine power to 609 horsepower without loss of operational life - even a patched engine in practice runs 400 km without the need for major repairs.

The most important features

The model range for the BMW 7 series BMW N73B60, N74B60, N74B66 is the embodiment of a reliable design and high power potential. The engines are moderately voracious and hardy, but they need regular maintenance.

The model range for the BMW 7 series BMW N73B60, N74B60, N74B66 is the embodiment of a reliable design and high power potential. The engines are moderately voracious and hardy, but they need regular maintenance.

The turbocharged V12 series is suitable for fans of powerful cars who do not care about the cost of maintenance and the price of components, and engines are not suitable for everyday use.