Honda R18A, R18A1, R18A2, R18Z1, R18Z4 engines

Content

The R-series engines appeared in early 2006, which was a small shock therapy in Honda's engineering history. The fact is that many motors created by the beginning of the 2000s were very outdated and there was a need to create new models.

In addition, new environmental standards put forward certain requirements for toxic emissions, which the B-, D-, F-, H-, ZC series did not meet. The 1,2 and 1,7 liter engines were replaced by the L series, which were immediately introduced into class B cars. The K series became a worthy receiver of two-liter engines, which quickly completed heavy cars. By the beginning of 2006, the serial production of Honda Civic and Crossroad cars belonging to class C was brewing.

The company's engineers were worried about one question - what kind of heart to give these cars? As you know, the authority of the old models rested on moderate appetites. The L-series engines would certainly endow them with efficiency, but with a power of 90 hp. dynamics should be forgotten forever. At the same time, the K-series engines would be unreasonably powerful for this class of machine. A few years later, Honda designed and put into production the motors of the series: R18A, R18A1, R18A2, R18Z1 and R18Z4. The whole series had the same characteristics, some models had minor improvements.

Technical specifications

The main characteristics of the internal combustion engine are presented in the table below:

| Engine volume, cm³ | 1799 |

|---|---|

| Power, hp / at rpm | 140/6300 |

| Torque, Nm / at rpm | 174/4300 |

| Supply system | injector |

| Type | in-line |

| Number of cylinders | 4 |

| Number of valves in the cylinder | 4 |

| The piston stroke, mm | 87.3 |

| Cylinder diameter, mm | 81 |

| Compression ratio | 10.5 |

| Fuel consumption, per 100 km (city/highway/mixed) | 9.2/5.1/6.6 |

| Oil grade | 0W-20 0W-30 5W-20 5W-30 |

| Oil change is carried out, km | 10000 (optimally every 5000) |

| Oil volume when changing, l | 3.5 |

| Resource, km | Up to 300 thousand |

The main parameters

R18A is an injection engine with a volume of 1799 cm³. Compared to its predecessor D17, the motor is quite strong. The torque is 174 Nm, the power is 140 hp, which allows you to accelerate heavy C-class cars quite quickly. Fuel consumption largely depends on the driving style - with a measured movement, without sudden accelerations, the consumption is 5,1 liters per 100 km. In the city, consumption increases to 9,2 liters, and in mixed mode - 6,6 liters per 100 km. The average engine life is 300 thousand kilometers.

External Description

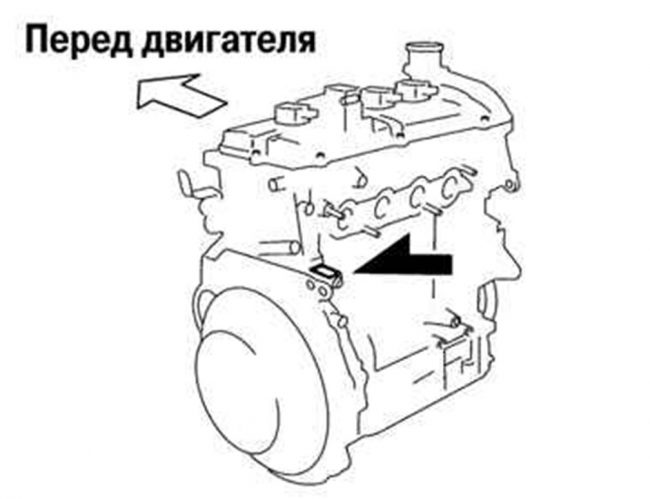

The first thing to start researching a car when buying is to search for factory plates with the car body number and engine number. Our power unit has the number plate located near the intake manifold, as shown in the figure below:

The first thing that catches your eye is the tight fitting of the engine compartment, which is not uncommon for 16-valve engines. The body and cylinder head are made of high-strength aluminum alloy, which significantly lightens the overall weight. The valve cover of this brand is represented by high-thermal plastic, instead of the usual aluminum options. Such an economical move turned out to be quite justified - according to the reviews of motorists - for 7-10 years of operation there are no deformations that give an oil leak. The intake manifold is also made of aluminum, the external shape is made with variable geometry.

Design features

The R18A engine series are in-line four-cylinder engines. That is, four cylinders are machined in the block, arranged sequentially in one row. The cylinders contain pistons that drive the crankshaft. The piston stroke is 87,3 mm, the compression ratio is 10,5. The pistons are connected to the crankshaft by lightweight and high-strength connecting rods, made for the first time for this model. The length of the connecting rods is 157,5 mm.

The design of the aluminum head remained unchanged - seats for the camshaft and valve guides are machined in its body.

Timing features

The gas distribution mechanism is chain, 16-valve (each cylinder has 2 intake and 2 exhaust valves). One camshaft acts on the valves through cylindrical tappets. There are no hydraulic compensators in the system, so it is necessary to periodically adjust the valves in a planned manner. Despite the simplicity of the timing design, the presence of the I-VTEC variable valve timing system allows you to adjust the degree of opening and closing of the valves depending on the load. This option allows you to significantly save on fuel and use engine resources more efficiently. The gas distribution system of our motor fails very rarely.

Power system features

The power supply system is represented by a pump, fuel lines, a fine filter, a fuel pressure regulator and injectors. Air supply is provided by air ducts, an air filter and a throttle assembly. Features are the presence of electronic control of the degree of opening of the throttle, depending on the number of revolutions. Also in the power system there is an EGR exhaust system that recirculates them through the combustion chamber. This system reduces the amount of toxic emissions into the atmosphere.

Oil system

The oil system is represented by an oil pump located in the engine sump. The pump pumps oil, which passes under pressure through the filter and is fed through the drillings to the rubbing elements of the engine, flowing back into the sump. In addition to reducing friction, the oil performs the function of cooling the pistons, supplied under pressure from special holes in the bottom of the connecting rod. It is important to change the oil every 10-15 thousand kilometers, most optimally - after 7,5 thousand km. Engine oil circulating in the lubrication system for more than 15 thousand km loses its properties, its “waste” appears due to settling on the cylinder walls. Recommended brands are shown in the table above.

Cooling and ignition system

The cooling system is of a closed type, the liquid circulates through the channels in the motor housing, where heat exchange takes place. Radiators, pump, thermostat and electric fans ensure uninterrupted operation of the cooling system. The volume varies depending on the brand of the engine. As a coolant, the manufacturer strongly recommends the use of Honda antifreeze type 2, provided for this series of engines.

The ignition system is represented by a coil, candles, an electronic control unit and high-voltage wires. There were no structural changes in the cooling and ignition systems.

Types of motors of the R18 series

The engine series includes several models with slight differences:

- R18 A1 - this model with identical characteristics of the R18 A motor, designed for cars in Japan and North America;

- R18 A2 - this engine was installed on European cars. Characteristics are no different from R18 A;

- R18 Z1 - modified version, 141 hp, torque remained unchanged. The uniqueness of the design lies in the modernization of the gas distribution system, which at low speeds turns off 1 inlet valve in each cylinder. Intake manifold switches at 5000 rpm;

- R18 Z1 - is a copy of the previous model, installed on European Honda Civic cars;

- The R18 Z9 is a motor similar to the R18 Z1, designed for the Honda HR-V.

Reliability

In general, the R18 series has established itself as a reliable motor that rarely fails. The secret is that there is not much to break here - the design of these power units is very simple. One camshaft serves the intake and exhaust valves at the same time, and the timing chain is much more reliable than the belt. The high-strength aluminum body of the engine and cylinder heads can withstand temperature fluctuations perfectly. As practice shows, the high-thermal plastic of the valve cover does not deform even after 5-7 years. If you follow the recommendations of the manufacturer and carry out timely maintenance of the motor, the engine will cover more than 300 thousand kilometers.

Watch this video on YouTube

Maintainability and weaknesses

Any sensible minder will tell you - the simpler the motor is, the more reliable and easy it is to maintain. The R18 series ICEs are designed like standard in-line four-cylinder engines that any car service employee is familiar with. A small problem is only the inaccessibility of some components and assemblies in the engine kit. Among the common problems of the R18 engine are:

- Metal knocking during operation is the first sore that appears every 30-40 thousand kilometers. The motor has no hydraulic lifters and planned wear makes itself felt. Valves need to be adjusted.

- If the engine speed floats, it shakes when gas is applied - check the timing chain. With a solid run, the chain is stretched, it needs to be replaced.

- Noise during operation - often the cause may be the failure of the tension roller. Its resource is 100 thousand kilometers, but sometimes a little less.

- Excessive vibration - in cold weather, these motors shake a little during operation, but if the vibrations are significant, you need to carefully inspect the engine mounts, they may need to be replaced.

Engine tuning

According to the reviews of car owners, all the improvements of this brand of engines significantly affect the resource and appetites of the motor. Therefore, whether to be content with factory parameters or to carry out tuning is a purely individual decision.

The two most common R18 modifications are:

- Turbine and compressor installation. Thanks to the installation of a compressor that provides forced air injection into the combustion chamber, the power of the internal combustion engine is increased to 300 horsepower. The modern automotive market offers a wide range of compressors and turbines that cost solid money. The installation of such improvements must necessarily include the replacement of a high-strength steel cylinder-piston group, as well as nozzles and a fuel pump.

- Atmospheric tuning. The most budget option is to make chip tuning, cold intake and direct exhaust. This innovation will add an additional 10 horsepower. The undoubted advantage is that the refinement does not particularly affect the life of the engine. A more expensive option includes installing an intake receiver, replacing pistons with a compression ratio of 12,5, injectors and altering the cylinder head. This option will cost significantly more and add about 180 horsepower to the car.

List of cars on which this engine was installed:

- Honda Civic;

- Honda Stream;

- Honda Cossroad.