Hyundai / Kia R-Series engines - 2,0 CRDi (100, 135 kW) and 2,2 CRDi (145 kW)

The once "gasoline" Korean automakers are now proving they can produce a quality diesel engine as well. A prime example is the Hyundai/Kia Group, which has delighted many oil aficionados with its 1,6 (1,4) CRDi U-series. These engines are characterized by solid dynamics, reasonable fuel consumption and good reliability, time-tested. CRDi units of the D series manufactured by the Italian company VM Motori in two power options (2,0 - 103 kW and 2,2 - 115 kW) were replaced at the turn of 2009-2010. On completely new engines of our own design, called the R-series.

The once "gasoline" Korean automakers are now proving they can produce a quality diesel engine as well. A prime example is the Hyundai/Kia Group, which has delighted many oil aficionados with its 1,6 (1,4) CRDi U-series. These engines are characterized by solid dynamics, reasonable fuel consumption and good reliability, time-tested. CRDi units of the D series manufactured by the Italian company VM Motori in two power options (2,0 - 103 kW and 2,2 - 115 kW) were replaced at the turn of 2009-2010. On completely new engines of our own design, called the R-series.

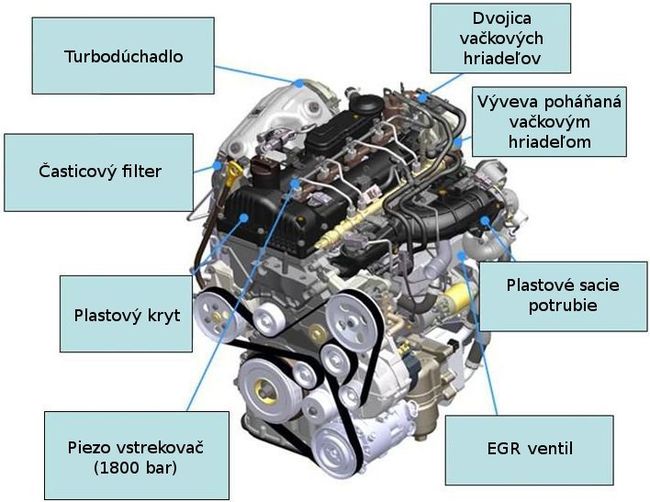

The R series motors are available in two displacement classes: 2,0 and 2,2 liters. The smaller version is used for the compact SUVs Hyundai ix35 and Kia Sportage, the larger version is used for the second generation Kia Sorento and Hyudai Santa Fe. The 2,0 CRDi is available in two power options: 100 and 135 kW (320 and 392 Nm), while the 2,2 CRDi delivers 145 kW and a maximum torque of 445 Nm. According to the declared parameters, both engines are the best in their class (engines with supercharging from only one turbocharger).

As mentioned, the previous D-series engines started being installed in Hyundai/Kia vehicles around the turn of the millennium. Gradually, they went through several stages of evolution and throughout their careers represented a decent motorization. However, they did not reach the top of the class due to their dynamics, and also had a slightly higher consumption compared to competitors. For the same reasons, Hyundai / Kia Group introduced completely new engines of its own design. Compared to its predecessors, the new R-series has several differences. The first is a sixteen-valve timing mechanism, which is now controlled by not one, but a pair of camshafts through rocker arms with pulleys and hydraulic tappets. In addition, the timing mechanism itself is no longer driven by a toothed belt, but by a pair of steel chain links that require no maintenance under normal operating conditions. More specifically, the chain drives the exhaust-side camshaft, from which the camshaft drives the intake-side camshaft.

In addition, the pump required to operate the brake booster and vacuum actuators is driven by the camshaft and is not part of the alternator. The water pump is driven by a flat belt, while in the previous generation the drive was secured by a toothed timing belt, which in some cases can contribute to damage - breaking the belt and subsequent serious engine damage. The turbocharger and location of the DPF, combined with the oxidation catalytic converter which sits just below the turbocharger, has also been changed to keep the exhaust gases as hot as possible and not unnecessarily cool as in the previous generation (the DPF was located under the car). Mention should also be made of the more significant differences between the two 2,0 CRDi performance options. They differ, as usual, not only in turbo pressure, injection or other control unit program, but also in a different shape of the pistons and a lower compression ratio of the stronger version (16,0:1 vs. 16,5:1).

Injection is carried out by the 4th generation Common Rail system with Bosch CP4 injection pump. The injectors are piezoelectrically controlled with a maximum injection pressure of up to 1800 bar, and the entire process is controlled by Bosch EDC 17 electronics. Only the cylinder head is made of light aluminum alloys, the block itself is made of cast iron. Although this solution has certain disadvantages (longer heating time or more weight), on the other hand, such a device is very reliable and cheaper to manufacture. The engine contains an exhaust gas recirculation valve, continuously controlled by an electric motor, the servo motor is also responsible for adjusting the stator vanes in the turbocharger. Efficient oil cooling is provided by an oil filter with an oil-water heat exchanger.

Of course, compliance with the Euro V emission standard, including the particulate filter, is a matter of course. Since the 2,2 CRDi engine entered the Sorento II model in 2009, the manufacturer received Euro IV approval, which means there is no DPF filter. A positive signal for the consumer, which is probably not necessary. While the failure rate or life of DPF filters has improved significantly, high mileage or frequent short runs still significantly affect the reliability and life of this environmental benefit. So Kia allowed a very successful engine to be used in the second generation Sorente, even without the time-consuming DPF filter. Such a unit contains a smaller exhaust gas recirculation cooler, which in both versions has a jumper (cold - cold engine). In addition, only conventional steel glow plugs are used instead of ceramic ones, which are more expensive but also more resistant to long-term loads. In modern diesel engines, the glow plugs are also run for some time after starting (sometimes during the entire warm-up phase) to reduce the formation of unburned hydrocarbons (HC) and thus improve engine operating culture. Reheating is necessary due to the progressively lower compression pressure, which also results in lower compressed air temperatures during compression. It is precisely this low heat of compression that may not be sufficient for the low emissions required by increasingly stringent standards.