Toyota 2E, 2E-E, 2E-ELU, 2E-TE, 2E-TELU, 2E-L, 2E-LU engines

In 1984, almost in parallel with the 1E engine, with a delay of several months, production of the 2E engine began. The design has not undergone significant changes, but the working volume has increased, which amounted to 1,3 liters. The increase was due to the boring of the cylinders to a larger diameter and an increase in the piston stroke. To increase power, the compression ratio was further raised to 9,5:1. The 2E 1.3 motor was installed on the following Toyota models:

- Toyota Corolla (AE92, AE111) - South Africa;

- Toyota Corolla (EE90, EE96, EE97, EE100);

- Toyota Sprinter (EE90, EE96, EE97, EE100);

- Toyota Starlet (EP71, EP81, EP82, EP90);

- Toyota Starlet Van (EP76V);

- Toyota Corsa;

- Toyota Conquest (South Africa);

- Toyota Tazz (South Africa);

- Toyota Tercel (South America).

In 1999, the internal combustion engine was discontinued, only the production of spare parts was retained.

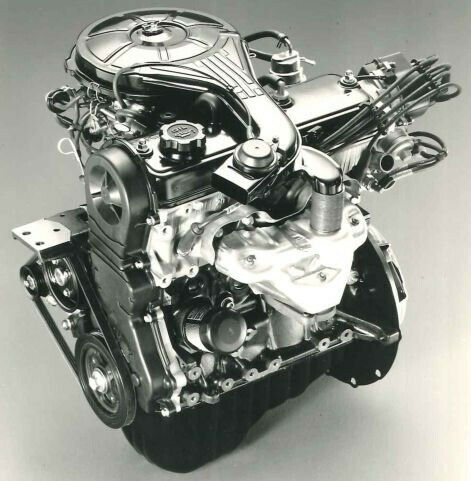

Description 2E 1.3

The basis of the motor, the cylinder block, is made of cast iron. An in-line four-cylinder ICE layout was used. The location of the camshaft is top, SOHC. The timing gear is driven by a toothed belt. To reduce the weight of the engine, the cylinder head is made of aluminum alloy. Also, the use of a hollow crankshaft and relatively thin cylinder walls contribute to a reduction in engine weight. The power plant was installed transversely in the engine compartment of cars.

The head has 3 valves for each cylinder, which are driven by one camshaft. There are no phase shifters and hydraulic compensators, valve clearances need periodic adjustment. Valve seals are not reliable. Their failure is accompanied by a sharp increase in oil consumption, its entry into the combustion chamber and the formation of unwanted soot. In advanced cases, detonation knocks are added.

The power system is a carburetor. Sparking is provided by a non-contact ignition system with a mechanical distributor and high-voltage wires, which caused a lot of criticism.

The motor, like its predecessor, does not have a high resource, but has a reputation as a reliable hard worker. The unpretentiousness of the unit, ease of maintenance is noted. The only component that requires skilled care is the carburetor, due to the complex adjustment.

The power of the unit was 65 hp. at 6 rpm. A year after the start of production, in 000, modernization was carried out. There were no fundamental changes, the return in the new version increased to 1985 hp. at 74 rpm.

Since 1986, distributed electronic fuel injection has been used instead of a carburetor power system. This version was designated 2E–E, and produced 82 hp at 6 rpm. The version with an injector and a catalytic converter was designated 000E-EU, with a carburetor and a catalyst - 2E-LU. On a Toyota Corolla car with an injection engine of 2, fuel consumption was 1987 l / 7,3 km in the urban cycle, which is a very good indicator for that time, in relation to a motor of such power. Another plus of this version was that, along with the outdated ignition system, the problems associated with it were gone.

Cars equipped with this engine were popular. The flaws of the power unit were covered by ease of maintenance, economy, maintainability of vehicles.

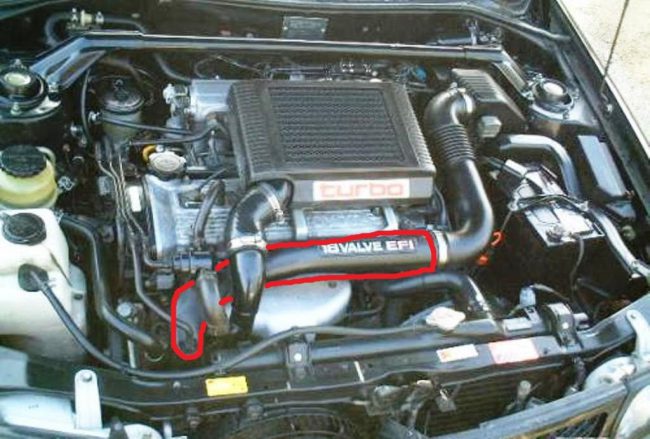

The result of further modernization was the 2E-TE engine, which was produced from 1986 to 1989 and was installed on a Toyota Starlet car. This unit was already positioned as a sports unit, and has undergone a deeper modernization. The main difference from its predecessor is the presence of a turbocharger. The compression ratio was reduced to 8,0:1 to avoid detonation, the maximum speed was limited to 5 rpm. At these speeds, the internal combustion engine produced 400 hp. The next version of the turbo engine under the designation 100E-TELU, that is, with electronic injection, turbocharging and a catalyst, was boosted to 2 hp. at 110 rpm.

Advantages and disadvantages of 2E series engines

The 2E series engines, like any other, have their own advantages and disadvantages. The positive qualities of these motors can be considered low operating costs, ease of maintenance, high maintainability, with the exception of turbocharged engines. Versions with a turbine, among other things, have a significantly reduced resource.

The disadvantages include:

- Thermal loading, especially in severe operating conditions, respectively, the tendency to overheat.

- Bending of the valves when the timing belt breaks (except for the first version 2E).

- At the slightest overheating, the cylinder head gasket breaks through with all the ensuing consequences. The possibility of repeated grinding of the head softens the picture.

- Short-lived valve seals that need periodic replacement (usually 50 thousand km).

Carburetor versions were plagued by misfires and difficult adjustments.

Technical specifications

The table shows some characteristics of the 2E motors:

| 2E | 2E-E,I | 2E-TE, TELU | |

|---|---|---|---|

| Number and arrangement of cylinders | 4, in a row | 4, in a row | 4, in a row |

| Working volume, cm³ | 1295 | 1295 | 1295 |

| Supply system | carburetor | injector | injector |

| Maximum power, hp | 55 | 75 – 85 Feet | 100 – 110 Feet |

| Maximum torque, Nm | 75 | 95 – 105 Feet | 150 – 160 Feet |

| Block head | aluminum | aluminum | aluminum |

| Cylinder diameter, mm | 73 | 73 | 73 |

| The piston stroke, mm | 77,4 | 77,4 | 77,4 |

| Compression ratio | 9,0:1 | 9,5:1 | 8,0:1 |

| Gas distribution mechanism | SOHC | SOHC | SOHC |

| number of valves | 12 | 12 | 12 |

| Hydraulic compensators | no | no | no |

| Timing drive | belt | belt | belt |

| Phase regulators | no | no | no |

| Turbocharging | no | no | Yes |

| Recommended oil | 5W – 30 | 5W – 30 | 5W – 30 |

| Oil volume, l. | 3,2 | 3,2 | 3,2 |

| fuel type | AI-92 | AI-92 | AI-92 |

| Environmental class | EURO 0 | EURO 2 | EURO 2 |

In general, the engines of the 2E series, with the exception of turbocharged ones, enjoyed a reputation for not being the most durable, but reliable and unpretentious units, which, with proper care, more than justify the money invested in them. 250-300 thousand km without capital is not the limit for them.

Overhaul of the engine, contrary to the statement of Toyota Corporation about their disposability, does not cause any problems due to the simplicity of the design. Contract engines of this series are offered in sufficient quantity and in a wide price range, but a good copy will have to be looked for due to the great age of the engines.

Difficult to repair turbocharged versions. But they lend themselves to tuning. By increasing the boost pressure, you can add 15 - 20 hp without much hassle, but at the cost of reducing the resource, which is already low in relation to other Toyota engines.