Volkswagen engines: varieties, characteristics, problems and diagnostics

Content

- Overview of Volkswagen Group engines

- Self-diagnosis of the engine

- Volkswagen engine cooling system

The Volkswagen concern produces a fairly wide range of powertrains, which includes spark ignition gasoline engines and compression ignition diesel engines. The concern installs its own developments both on cars and trucks.

Overview of Volkswagen Group engines

The Volkswagen concern, founded in Berlin on May 28, 1937, declared the production of affordable cars with optimal technical characteristics as a priority. The machines had to meet the following requirements:

- the highest possible level of security;

- reliable engine;

- economical use of fuel;

- acceptable comfort;

- salon for four people;

- minimal impact on the environment;

- decent quality trim.

In other words, the concern was supposed to produce budget cars with a powerful and economical engine.

The evolution of Volkswagen engines

All engines manufactured by the Volkswagen Group are tested in the accredited test center Deutsches Institut für Normung. The units have an efficient direct injection system and an environmentally friendly exhaust system. The group has received several innovation awards for its engines.

Throughout its history, the concern has tried to make the engine more economical. The result of these studies was a unit that consumes 3 liters of fuel per 100 km. It was a three-cylinder diesel engine with a volume of 1,2 liters with an aluminum block, an injection system, a turbocharger and cooling of the supplied air. Reducing the number of cylinders slightly affected the dynamic characteristics of the engine. With minimal fuel consumption, the unit showed decent power due to:

- reducing the weight of the engine;

- reduce friction between contacting nodes and parts;

- increasing the efficiency of combustion of the air-fuel mixture;

- modernization of the injection system with exhaust gas turbocharger.

The first Volkswagen engines

In 1938, the VW Type 1 was launched, with the revolutionary F4 four-cylinder engine mounted at the rear and air-cooled. The unit had a volume of 1,131 liters and a capacity of 34 liters. With. In the process of evolution, the engine volume increased from 1,2 to 1,6 liters. The latest model was the perfect combination of performance, efficiency and reliability. Due to the design of the carburetor, optimal proportions were observed when forming a combustible mixture. The 1,6 liter engine laid the foundation for a line of engines for cargo and passenger vans.

Specifications of Volkswagen engines

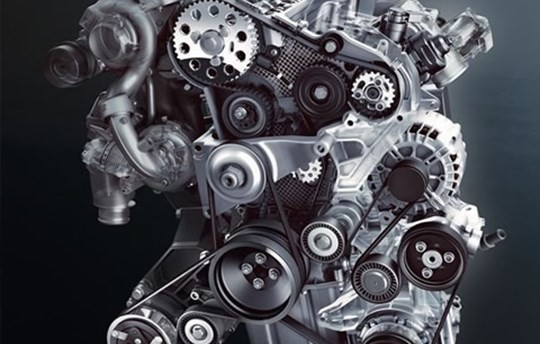

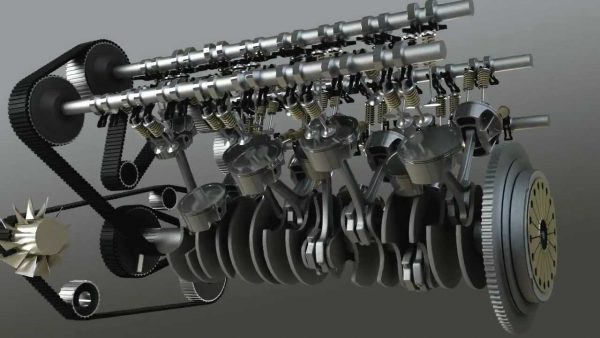

The standard Volkswagen engine is a four-cylinder unit with an overhead camshaft and water cooling. Usually the cylinder block, its head and pistons are made of aluminum alloy, and the crankshaft with three support bearings is made of forged steel.

Volkswagen engines have the following specifications:

- fuel consumed - gasoline or diesel fuel;

- cooling system - air or liquid;

- type of cylinder arrangement - in-line, V-shaped or VR;

- volume - from 1 to 5 l;

- power - from 25 to 420 liters. With.;

- fuel consumption - from 3 to 10 liters per 100 kilometers;

- number of cylinders — from 3 to 10;

- piston diameter - up to 81 mm;

- number of working cycles - 2 or 4;

- type of mixture ignition - spark ignition or compression ignition;

- the number of camshafts - 1, 2 or 4;

- the number of valves in the combustion chamber is 2 or 4.

TSI petrol engines are the perfect combination of performance and economy. Even at low speeds, they deliver maximum torque, and the carefully crafted combination of piston displacement, turbocharging and direct injection delivers even fuel delivery.

Volkswagen gasoline engines are characterized by:

- formation of the fuel mixture in the intake manifold or directly in the combustion chamber;

- ignition of the mixture from spark plugs;

- uniform combustion of the mixture;

- quantitative adjustment of the mixture;

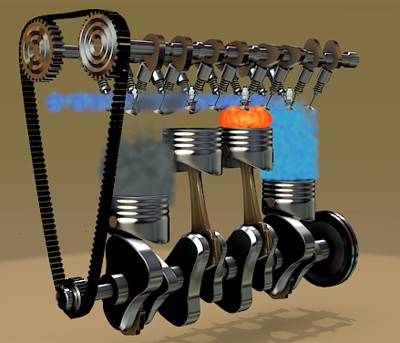

- four-stroke principle of operation with two revolutions of the crankshaft with an angle of 720 °.

Volkswagen TDI diesel engines with turbocharging and direct fuel injection are characterized by:

- profitability;

- high traction power;

- productivity;

- reliability in operation.

The operation of a Volkswagen diesel engine is characterized by the following points:

- formation of a mixture of fuel and air in the combustion chamber;

- self-ignition of fuel from heated compressed air;

- high compression ratio;

- high-quality preparation of the mixture;

- the principle of operation of a four-stroke engine for two revolutions of the crankshaft.

The advantages of Volkswagen gasoline engines are:

- low weight-to-power ratio (kg/kW);

- wide range of uses;

- good dynamics;

- low cost;

- all-weather;

- easy maintenance.

However, these units also have disadvantages. First of all it is:

- relatively high fuel consumption;

- weak traction at low speeds;

- increase in consumption when loading the cabin;

- fuel flammability.

The advantages of diesel engines include:

- low fuel consumption;

- high torque;

- lack of spark plugs;

- good handling at low speeds;

- good handling in high gears.

The disadvantages of diesels are:

- high requirements for fuel quality;

- seasonality of fuel (problem starting in cold weather);

- quite expensive service;

- the need for strict adherence to the frequency of changing oil and filters;

- high price.

Volkswagen engines for trucks

Vehicles carrying heavy loads are usually operated at low speeds and require increased engine power. The best option for them is an elastic diesel engine with an optimal ratio of its power and car weight. The higher the elasticity of the engine, the faster acceleration takes place. This is especially true in urban areas, where diesel units are much more efficient than gasoline ones.

Cylinder arrangement in Volkswagen engines

Depending on the location of the cylinders, there are:

- in-line engines;

- V-shaped engines;

- VR engines.

Each of the varieties has its own advantages and disadvantages.

Inline engine

A conventional piston engine is a series of cylinders arranged one behind the other. It is most often installed on cars and trucks and usually consists of four cylinders, the countdown of which starts from the flywheel side.

As an advantage of a four-stroke engine with a longitudinally symmetrical crankshaft, good dynamics and relatively low cost are usually noted. The disadvantage of this unit is the increased requirements for space in the engine compartment, necessary for the location of the block of four cylinders.

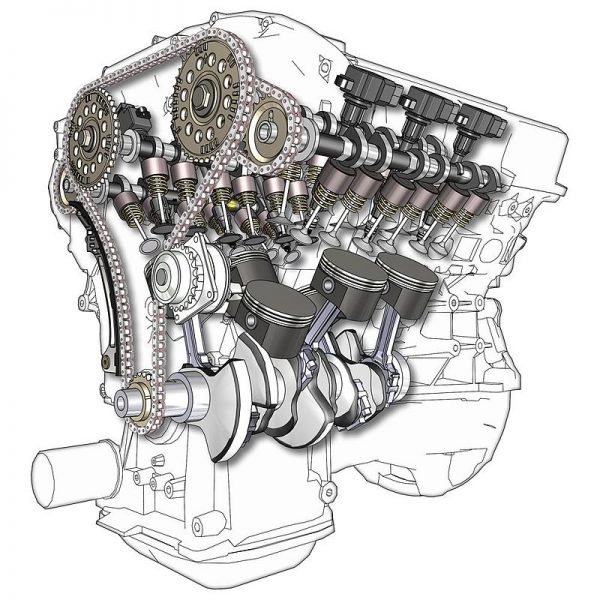

V-shaped engine

A V-shaped engine consists of several cylinders at an angle to each other. The tilt angle can reach 180°. Due to this, a larger number of cylinders can be placed in a limited space. All engines with eight or more cylinders are typically V-type (V6, V8 or V12). V4 units, compared to in-line counterparts, have a better weight-to-power ratio, but are more expensive to manufacture.

Compared to an in-line engine, the V-engine is more compact and lightweight. So, the V12 is only slightly longer than the six-cylinder in-line engine. The disadvantage is its more complex design, certain difficulties in balancing, a high level of vibration and the need to duplicate some nodes.

Video: 8-cylinder V-engine operation

VR engine

The VR engine developed by the concern is a symbiosis of a V-engine with an extremely low camber angle (15°) and an in-line unit. Its six cylinders are arranged at an angle of 15°. This is different from traditional V-engines, in which this angle is 60° or 90°. The pistons are located in the block in a checkerboard pattern. This design allows you to combine the multiplicity of the V-shaped engine with the small width of the in-line engine and significantly saves space in the engine compartment.

The VR engine also has a number of disadvantages:

- a large angle of inclination of the connecting rods leads to high radial loads on the pistons;

- the uneven length of the intake and exhaust channels affects the air supply and exhaust gases;

- the production of the cylinder head is quite expensive.

Characteristics of Volkswagen AG engines

The Volkswagen concern produces both petrol and diesel engines.

Volkswagen petrol engines

In the evolution of Volkswagen gasoline engines, several main models can be distinguished.

- Model EA111. For the first time, EA111 engines were installed in the mid-1970s on VW Polo cars. They were in-line three- and four-cylinder water-cooled gasoline engines. The camshaft was driven by a toothed belt from the crankshaft. The intermediate shaft controlled the oil pump and ignition distributor. EA111 engines were equipped with VW Polo, VW Golf, VW Touran models.

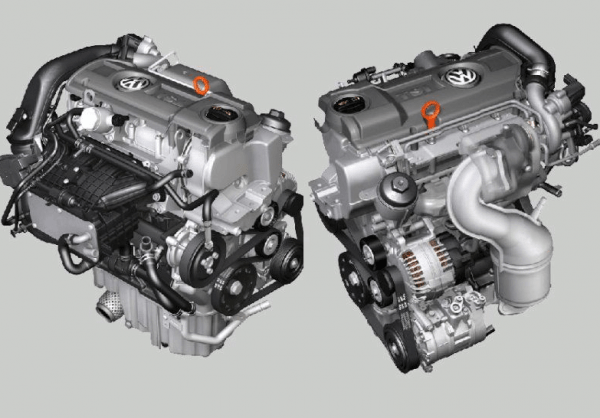

EA111 engines are used in VW Polo, VW Golf and VW Touran models

EA111 engines are used in VW Polo, VW Golf and VW Touran models - Model EA827. Serial production of EA827 engines began in 1972. Four- and eight-cylinder units had a reliable water cooling system and were installed on the VW Golf and VW Passat.

Serial production of EA827 engines began in 1972

Serial production of EA827 engines began in 1972 - Model EA113. EA113 engines have been installed in many cars - from Audi 80, Seat Leon, Škoda Octavia to VW Golf and VW Jetta. Motors of this series were awarded at the international competition International Engine of the Year.

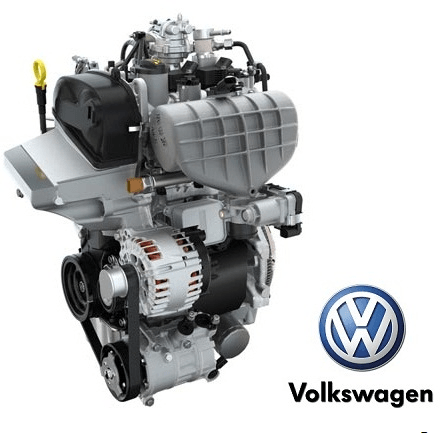

- Model EA211. The units of this EA211 series are a modification of the four-cylinder TSI engines with turbocharging and direct injection. Compared with previous versions, the length of the engine has decreased by 50 mm. The weight of the aluminum alloy engine is 97 kg for the 1,2 TSI and 106 kg for the 1,4 TSI. To reduce weight, pistons with a flat bottom are installed. The unit has a dual-circuit cooling system. In the high temperature circuit, the engine is cooled by a mechanically driven pump, while the low temperature circuit includes an intercooler and a turbocharger housing.

The EA211 engine is a modification of the four-cylinder turbocharged direct injection TSI engine.

The EA211 engine is a modification of the four-cylinder turbocharged direct injection TSI engine. - Model EA888. Four-cylinder EA888 engine with power from 151 to 303 hp. With. has a dual injection system, injector positioning, thin-walled engine blocks, exhaust gas recirculation and cooling. There is no ignition coil. The engine of the Volkswagen Golf R400 concept car with an all-wheel drive system and a six-speed gearbox with a volume of 2,0 liters has a capacity of 400 hp. With. Up to 100 km / h, such a car accelerates in 3,8 seconds.

The use of a chain drive in the timing significantly increased the life of the EA888 series engine

The use of a chain drive in the timing significantly increased the life of the EA888 series engine

Table: specifications of Volkswagen gasoline engines

| Code | Volume, cm3 | Modification | power, kWt | Power, hp from. | Car model | Start of production, year | Discontinuation, year |

| 1 | 1100 | F4 | 18 | 25 | Type 1 | 1947 | 1954 |

| 1 | 1200 | F4 | 22 | 30 | Type 1 | 1954 | 1960 |

| 1 | 1500 | F4 | 31 | 42 | Type 2 | 1963 | 1964 |

| 1 | 1500 | F4 | 33 | 45 | Type 3 | 1961 | 1965 |

| 1V | 1600 | I4 | 45 | 60 | Gulf, Jetta | 1989 | 1992 |

| 2H | 1800 | I4 | 73 | 98 | Golf Convertible | 1989 | 1993 |

| ABS | 1791 | I4 | 66 | 90 | Golf, Wind, Passat | 1991 | 1994 |

| ADR | 1781 | I4 | 92 | 125 | Passat | 1996 | 1999 |

| ADX | 1300 | I4 | 41 | 55 | Polo | 1994 | 1995 |

| AGZ | 2324 | V5 | 110 | 150 | Golf, Bora, Passat | 1997 | 2001 |

| AJH | 1781 | I4T | 110 | 150 | Polo, Golf, Jetta, Passat | 2001 | 2004 |

| APQ | 1400 | I4 | 45 | 60 | Polo, Golf, Wind | 1995 | 1998 |

| AWM | 1781 | I4T | 125 | 170 | Jetta, New Beetle, Passat | 2002 | 2005 |

| BAN | 5998 | V12 | 309 | 420 | Phaeton | 2002 | — |

| BAR | 4163 | V8 | 257 | 349 | Touareg | 2006 | — |

In the table, the engines are arranged in accordance with the letter code. The pre-1965 VW Beetle and VW Transporter engines did not have a letter code. They are marked in the table with code 1.

Volkswagen diesel engines

The main representatives of the Volkswagen diesel engine family are the following units.

- Model EA188. The engine design uses two-valve technology and an injection pump. Versions are available with a volume of 1,2 to 4,9 liters with a number of cylinders from 3 to 10. The cylinder head of more powerful units is made of cast iron, less powerful ones are made of aluminum with cast iron liners.

To compensate for unwanted inertia, the engine is equipped with a balance shaft driven by a chain from the crankshaft

To compensate for unwanted inertia, the engine is equipped with a balance shaft driven by a chain from the crankshaft Model EA189. The engines of this series are four-cylinder (1,6-2,0 l) and three-cylinder (1,2 l) units. The engine has a turbocharger, a low-temperature exhaust gas recirculation system and a diesel particulate filter. The intake manifold is equipped with flaps that continuously regulate the flow of incoming air. At low RPM, these dampers close, and when the engine speed increases to 3000 RPM, they are fully open.

The cylinder block is made of aluminum and has two camshafts

The cylinder block is made of aluminum and has two camshafts- Model VW EA288. The engines of this series are represented by three- and four-cylinder versions. In the case of three cylinders, the block itself is made of aluminum, and in the case of four, it is made of cast iron. Each cylinder has four valves. The engine is designed with two overhead camshafts driven by a toothed belt. To speed up the heating of the unit, the cooling system is divided into several circuits. The coolant passes through the cylinder head and the EGR cooler.

- Model EA898. In 2016, the concern began to install eight-cylinder EA898 engines with a cylinder angle of 90 ° on a number of vehicles. Unit with a capacity of up to 320 liters. With. has a cast iron crankcase, four valves per cylinder, four camshafts, two water-cooled exhaust gas turbochargers and variable turbine geometry. At crankshaft speeds up to 2200 rpm, one turbocharger and one exhaust valve per cylinder operate, and as the rotation speed increases, all exhaust valves open. The second turbocharger is charged with gas from the second exhaust valves. If the crankshaft starts to rotate faster than 2700 rpm, all four valves in the cylinders begin to work.

The eight-cylinder V-shaped engine has a volume of 3,956 liters

The eight-cylinder V-shaped engine has a volume of 3,956 liters

Table: Volkswagen diesel engine specifications

| Code | Volume, cm3 | Modification | power, kWt | Power, hp from. | Car model | Start of production, year | Discontinuation, year |

| 1Z | 1896 | I4T | 66 | 90 | Polo, Golf, Sharan, Passat | 1993 | 1997 |

| AAB | 2370 | I5 | 57 | 77 | Transport, Syncro | 1990 | 1998 |

| AAZ | 1896 | I4T | 55 | 75 | Golf, Wind, Passat | 1991 | 1998 |

| AEF | 1900 | I4 | 48 | 64 | Polo, Caddy | 1994 | 1996 |

| AFN | 1896 | I4T | 81 | 110 | Golf, Vento, Passat, Sharan | 1995 | 1999 |

| EGR | 1896 | I4T | 66 | 90 | Polo, Golf, Jetta | 1999 | 2001 |

| AHF | 1896 | I4T | 81 | 110 | Gulf, Jetta | 1997 | 2006 |

| ahh | 1896 | I4T | 66 | 90 | Passat | 1996 | 2000 |

| A.J.M | 1896 | I4T | 85 | 116 | Golf, Jetta, Passat | 1998 | 2002 |

| AJS | 1896 | I4T | 230 | 313 | Phaeton | 2002 | 2006 |

| AKN | 4921 | V10T | 110 | 150 | Passat | 1999 | 2003 |

| SALE | 2496 | V6T | 66 | 90 | Polo, Jetta, Caddy | 1997 | 1999 |

| ALH | 1896 | I4T | 66 | 90 | Polo, Golf, Jetta, New Beetle | 1997 | 2004 |

| ARL | 1896 | I4T | 110 | 150 | Gulf, Jetta | 2000 | 2006 |

| ASV | 1896 | I4T | 81 | 110 | Polo, Golf, Jetta | 1999 | 2006 |

Video: Volkswagen W8 engine operation

Watch this video on YouTube

Factories producing engines for Volkswagen cars

The Volkswagen Group is the largest automaker in the world. The number of employees is 370 thousand people who work at 61 plants in 15 European countries, North and South America, Asia and Africa. Up to 26600 vehicles are produced annually and sold in 150 countries. The main centers for the production of Volkswagen powertrains are:

- Volkswagen plant in Chemnitz. It is part of Volkswagen Sachsen GmbH. Produces four-cylinder gasoline and diesel engines with direct fuel injection and components for TSI units. It produces about 555 thousand engines annually. It is considered a center of expertise for innovative technologies. Much attention is paid to the issues of reducing fuel consumption and environmental friendliness of emissions, with a focus on CO2. The plant employs about 1000 people.

Technical experts from the Chemnitz plant played a leading role in advancing common rail diesel technology

Technical experts from the Chemnitz plant played a leading role in advancing common rail diesel technology - Volkswagen factory in Dresden. It was launched in December 2001. Includes VW Phaeton assembly area with hand-crafted luxury interior. Approximately 6000 cars are produced per year. Realizes the concept of combining conveyor and manual work. The buyer can observe the assembly of the car in the production area of 55000 m2. The finished car is waiting for the owner in a glass tower 40 meters high. The company employs about 800 people.

Dresden plant includes VW Phaeton assembly area with hand-crafted luxury interior

Dresden plant includes VW Phaeton assembly area with hand-crafted luxury interior - Volkswagen factory in Salzgitter. It is the largest engine manufacturer in the world. Daily on an area of 2,8 million m2 up to 7 petrol and diesel engines are assembled in 370 variants for VW, Audi, Seat, Škoda and Porsche Cayenne. It is famous for the model of a sixteen-cylinder power unit with a capacity of 1000 liters. With. for the Bugatti Veyron. In addition, it produces engine components for other industries. The 50 millionth engine was recently released (it turned out to be the TDI unit of the EA288 series for the new VW Golf). The plant employs about 6000 people.

The Volkswagen plant in Salzgitter is the largest engine manufacturer in the world.

The Volkswagen plant in Salzgitter is the largest engine manufacturer in the world. - Volkswagen plant in Kaluga. It is located in the Grabzevo technology park in Kaluga. It is the production center of Volkswagen in Russia. Plant with an area of 30 thousand m2 supplies engines for all Russian-assembled Volkswagen cars. The production capacity is 150 thousand engines per year. In 2016, the plant's production accounted for about 30% of the total number of cars in Russia with locally produced engines.

The plant in Kaluga supplies engines for all Russian-assembled Volkswagen cars

The plant in Kaluga supplies engines for all Russian-assembled Volkswagen cars

Contract engines

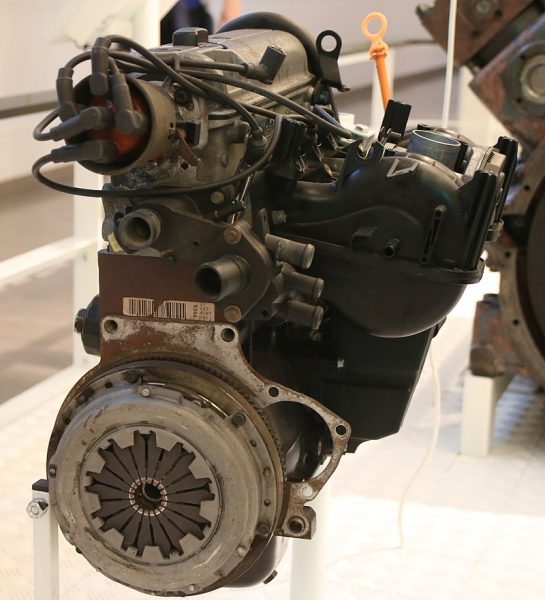

Any engine has a limited service life. After this resource, the car owner can:

- make a major overhaul of the native engine;

- purchase under a contract in Europe or America and install a used engine.

The contract motor fully complies with the technical requirements, is a working unit dismantled from a similar car.

All contract engines are pre-sale tested. Suppliers usually adjust all systems, do a trial run and guarantee trouble-free operation and a long service life. In addition to contract engines, technical documents, attachments and mounting elements are included.

Overhaul of a car engine is not always advisable. Especially if this model is already out of production.

The advantages of the engine purchased under the contract are:

- factory quality;

- work on high-quality fuel;

- little wear;

- large operational resource;

- use of high-quality lubricants;

- caring attitude from the former owners;

- strict observance of maintenance standards;

- dealer service;

- low cost compared to a new unit.

The disadvantages of such engines include:

- high mileage of foreign cars;

- inability to check the service life;

- lack of guarantees that the former owner will comply with the manufacturer's recommendations.

You should not purchase a power unit older than seven years. This is true for diesel engines.

Volkswagen engine life and manufacturer's warranty

Determining the degree of engine wear is quite difficult, since it depends on:

- resource regulated by the manufacturer;

- operating conditions;

- vehicle load;

- driving style.

Volkswagen guarantees that every part and assembly of the car meets the standards. This warranty is valid for one year or 20 km (whichever occurs first) from the date of purchase for individual parts and for 4 years or 100 km for the entire vehicle.

The reliable mechanism does not cause trouble with increased wear of parts with regular replacement of engine oil.

The warranty is terminated in cases caused by:

- misuse;

- negligence during operation;

- change and modification of components and assemblies;

- incorrectly carried out repairs;

- incorrect adjustment of individual nodes;

- intentional damage to parts;

- using parts and consumables that do not match this model;

- use of vehicles for competitive and off-road purposes;

- non-compliance with the recommended service intervals and operating requirements;

- collision with objects;

- vandalism of others;

- environmental damage;

- floods;

- accidents;

- fire.

Operating Tips

When buying a new car to extend the life of the engine, experts recommend paying attention to the following points:

- The first thousand kilometers on a new car should not be driven at high speeds. The crankshaft speed should not exceed 75% of the maximum possible value. Otherwise, oil consumption will increase and wear of the inner surface of the cylinders will begin. This can significantly reduce the resource of the power unit.

- The engine should be warmed up before driving. This condition is especially important for turbo engines and diesel engines.

- In new diesel engines, the oil level should be checked at every refueling.

- The engine maintenance interval recommended by Volkswagen must be strictly observed.

Self-diagnosis of the engine

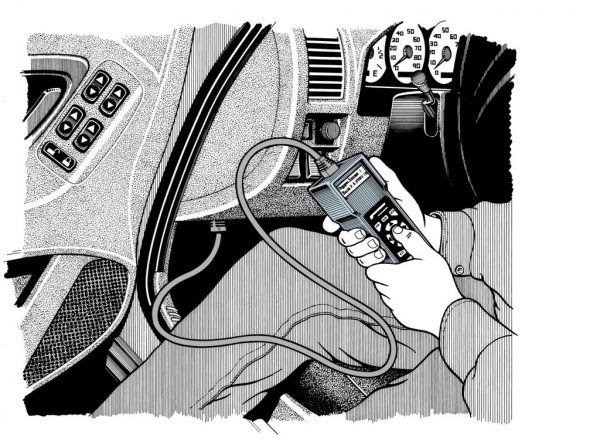

In a modern car, the engine control unit controls the operation of sensors and main components. Possible malfunctions are indicated by signal lamps in the instrument cluster - for example, the Check Engine indicator. In addition, through a standard OBD-II port, you can connect diagnostic equipment and get detailed information about the operation of individual systems by reading fault codes.

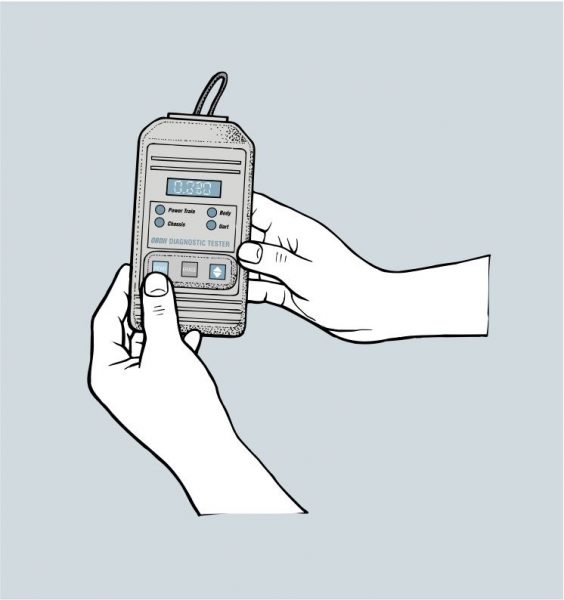

Necessary diagnostic tools

For computer diagnostics you will need:

- a diagnostic device corresponding to the vehicle's electronic system;

- computer or smartphone to decrypt the received information.

Troubleshooting algorithm for the OBD-II diagnostic adapter

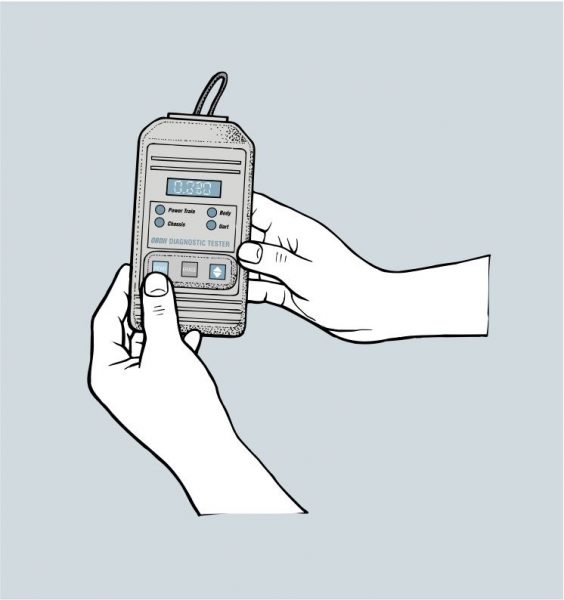

- Connect the adapter with the car turned off.

- Insert the scanner into the OBD-2 port.

Through a standard connector, you can connect various scanning devices

Through a standard connector, you can connect various scanning devices - Turn on the ignition. The connected scanner will turn on automatically.

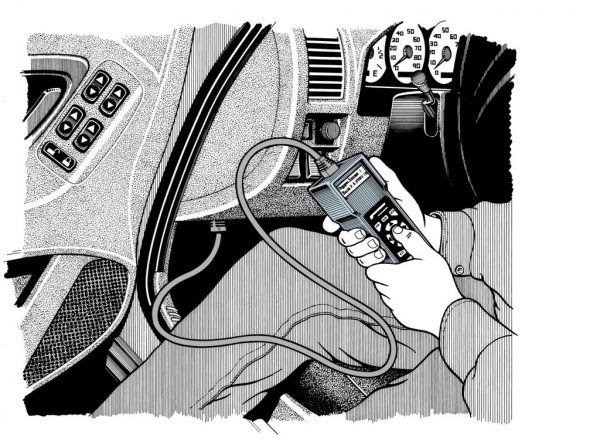

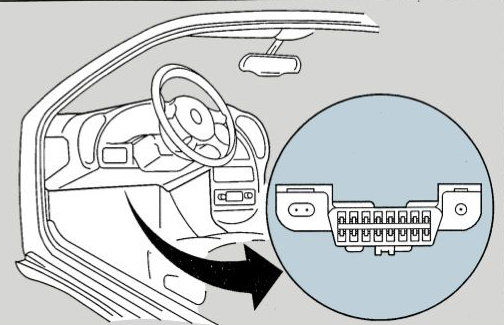

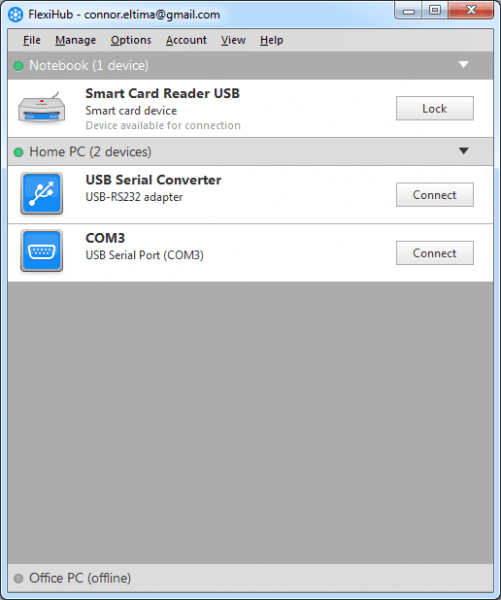

With a large number of adapter functions, the possibilities for detecting hidden faults are expanded

With a large number of adapter functions, the possibilities for detecting hidden faults are expanded - Find a scanning device on a computer or smartphone - it will be defined as a standard COM port connection or a bluetooth device.

The program will allow any car owner to understand the causes of engine failure

The program will allow any car owner to understand the causes of engine failure

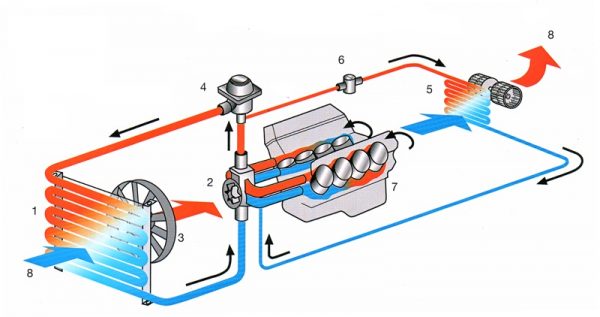

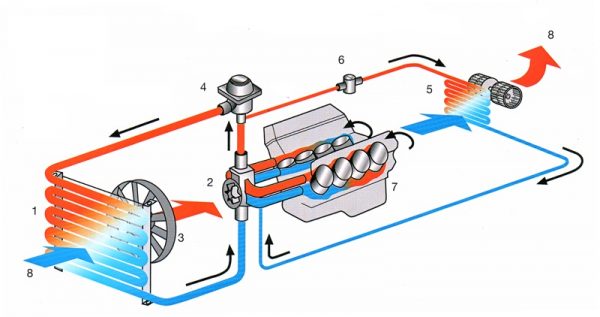

Volkswagen engine cooling system

The smooth operation of Volkswagen engines is largely determined by the efficiency and reliability of the cooling system, which is a closed circuit connecting the power unit, radiator and pipelines. Coolant (coolant) circulates through this circuit. The heated liquid is cooled in the radiator. The basis of the coolant is ethylene glycol, which is stable over a wide temperature range. The manufacturer recommends using only certain brands of coolant.

Engine coolant is usually colored so any leaks are easy to spot.

The water pump provides forced circulation of coolant through the cooling circuit and is driven by a belt. The pipelines of the Volkswagen engine cooling system consist of hoses, a radiator and an expansion tank. The temperature control devices include sensors, a thermostat, a radiator and expansion tank cap and a fan. All these elements function independently of the power unit. Temperature control allows you to adjust the performance of the engine and the composition of the exhaust gases.

Cooling system malfunctions

Most cooling system problems are the result of a lack of proper maintenance of its elements and untimely replacement of the coolant. The radiator and pipes are subject to wear, reducing cooling efficiency.

The main symptoms of malfunctions are small spots of coolant under the car after overnight parking and a strong smell of coolant when driving.

The most common cooling system problems are:

- low coolant level, leading to the appearance of air pockets, overheating and accelerated corrosion of exposed metal surfaces;

- the use of low-quality coolant or a type not recommended by the manufacturer;

- leakage or blockage of the radiator and expansion tank;

- water remaining in the system after flushing it;

- damage to the water pump drive belt;

- coolant leak.

You should not joke with the cooling system, so you should periodically check the fluid level.

If the engine overheats significantly, the cylinder head may be deformed and the effectiveness of the sealing gasket will decrease.

Trouble-shooting

You can keep your cooling system in good working order by following these simple procedures:

- daily inspection of the system for coolant leaks;

- control of the composition of the coolant, the exclusion of water entering the system;

- complete flushing of the system after draining the old coolant;

- periodic cleaning of the radiator from leaves, debris and dirt;

- periodically check the tension and condition of the pump drive belt.

Video: fixing a coolant leak on a VW Jetta

Watch this video on YouTube

Prevention of the cooling system involves the following actions:

- periodic cleaning of the engine compartment;

- coolant replacement every five years;

- replacement of hoses every two years;

- thermostat replacement at high engine temperature;

- tension adjustment and timely replacement of the water pump belt;

- replacement of the pump at the first signs of a malfunction;

- checking and replacing the cooling fan and temperature sensors with a slow drop in engine temperature.

Obviously, the trouble-free operation of the cooling system is possible only with the correct operation of other systems and components of Volkswagen vehicles.

Thus, the range of engines of the Volkswagen concern is quite wide. Each potential car owner can choose a power unit in accordance with their wishes, financial capabilities and vehicle operating conditions.