Fiat 0.9 TwinAir two-cylinder engine

Double cylinder? After all, Fiat is nothing new. Not so long ago Fiat was making wholesale in Tychy, Poland, so-called. The "small" (Fiat 126 P), well known in our country, is driven by a thundering and vibrating air-cooled two-cylinder engine. After a relatively short hiatus (the two-cylinder Fiat 2000 was still in production in 126), the Fiat Group decided to re-enter the world of two-cylinder engines. The SGE two-cylinder engine is manufactured in Bielsko-Biala, Poland.

A bit of “less cylindrical” history

Many older motorists remember the days when a two-cylinder engine (non-turbocharged, of course) was a relatively common problem. In addition to the rattling "baby", many remember the first Fiat 500 (1957-1975), which had a two-cylinder engine in the rear, Citroen 2 CV (boxer engine) and the legendary Trabant (BMV - Bakelite Motor Vehicle). ) with a two-stroke two-cylinder engine and front-wheel drive. Before the war, the successful DKW brand had many similar models. The F1 was a pioneer of small wood-bodied cars from 1931, and the three-cylinder engine was used in various DKW types until the fifties. Two-cylinder bestsellers LLoyd in Bremen (1950-1961, both two- and four-stroke) and Glas from Dingolfing (Goggomobil 1955-1969). Even a small fully automatic DAF from the Netherlands used a two-cylinder engine until the XNUMXs.

Despite the popular belief that it is trivial to have less than four cylinders in a car, Fiat decided to take this step. The owners of the "world famous" HTP could talk about this. At the same time, it is well known that the two-cylinder engine has an advantageous volume to surface ratio of the combustion chambers, as well as low friction losses, which put this type of engine back on the agenda of many car manufacturers. Fiat has so far been the first to take on the task of transforming the once "screaming" and vibrating "broom" into a modest gentleman. After several assessments by the journalistic community, we can say that to a large extent he succeeded. Reduced consumption also contributes to the reduction of greenhouse gas emissions. Fiat maintains number one position in lowering fleet CO emission limits2 for 2009 an average of 127 g / km.

0,9 double cylinder SGE with an accurate volume of 875 cc3 was designed to replace some of the weaker versions of the long-standing FIRE four-cylinder. On the contrary, it should bring significant savings not only on consumption and CO emissions.2, but this is mainly a significant saving in size as well as in manufacturing costs. Compared to a similar four-cylinder engine, it is 23 cm shorter and a tenth lighter. In particular, it is only 33 cm long and weighs only 85 kg. The smaller dimensions and weight not only reduce production costs with less material, but also have a positive effect on the ride performance and the life of the chassis components. There are also better options for installing other elements that reduce consumption, such as installing an additional electric motor for hybrid units or a trouble-free conversion to LPG or CNG.

The first serial application of this engine was the 2010 Fiat, presented in Geneva and sold since September 500, equipped with an 85 horsepower (63 kW) version. According to the manufacturer, it produces on average only 95 g of C0.2 per kilometer, which corresponds to an average consumption of 3,96 l / 100 km. It is based on an atmospheric version with a capacity of 48 kW. The other two variants are already equipped with a turbocharger and offer 63 and 77 kW of power. The engine has the TwinAir attribute, where Twin means two cylinders and Air is the Multiair system, i.e. electro-hydraulic timing, replacing the intake camshaft. Each cylinder has its own hydraulic unit with a solenoid valve that determines the opening time.

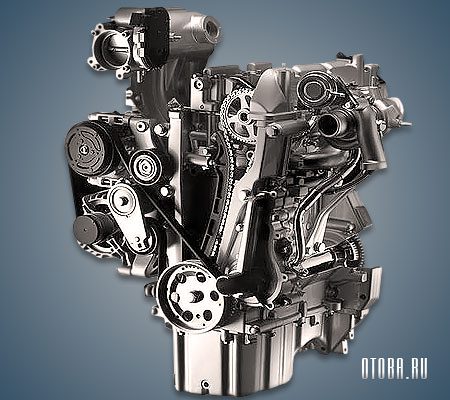

The engine has an all-aluminum construction and has indirect fuel injection. Thanks to the aforementioned MultiAir system, the entire timing chain has been limited to one reliable self-determining chain with a long tensioner that drives the exhaust side camshaft. Due to the design, it was necessary to install a balancing shaft rotating at double speed in the opposite direction to the crankshaft, from which it is directly driven by a spur gear train. The water-cooled turbocharger is part of the exhaust pipes and, thanks to its modern design and small size, provides an immediate response to the accelerator pedal. In terms of torque, the most powerful version is comparable to the naturally aspirated 1,6. Engines with a power of 85 and 105 hp equipped with a water-cooled turbine from Mitsubishi. Thanks to this technical perfection, there is no need for a throttle valve.

Why do you need a balancing shaft?

The refinement and quietness of an engine is directly related to the number of cylinders and design, with the rule that an odd and especially a small number of cylinders degrades engine performance. The problem arises from the fact that the pistons develop large forces of inertia when moving up and down, the influence of which must be eliminated. The first forces arise when the piston accelerates and decelerates at dead center. The second forces are created by the additional movement of the connecting rod to the sides in the middle of the bend of the crankshaft. The art of making motors is that all inertial forces interact with each other using vibration dampers or counterweights. The twelve-cylinder or six-cylinder flat-boxer engine is ideal for driving. The classic in-line four-cylinder engine experiences higher torsional vibrations that cause vibration. The pistons in the double cylinder are at the same time at top and bottom dead center, so it was necessary to install a balancing shaft against unwanted inertial forces.