Dual mass flywheel - how to check if it is working? What is double weight?

Content

- Dual mass flywheel - what does it do?

- Dvamasa - why?

- The role of double mass in the car

- Detailed construction of a dual-mass flywheel

- How dual mass works

- Symptoms of a damaged double mass - how to recognize them?

- How to test the dual mass flywheel?

- Causes of failure of the dual-mass flywheel

- What else affects the life of the double mass?

- Regeneration of the dual-mass flywheel - does it make sense?

- Double mass replacement cost

Dual mass flywheel - what does it do?

As mentioned in the introduction, the dual mass flywheel was developed primarily for diesel engines. The purpose of installing a dual-mass flywheel on such vehicles was to reduce the vibrations created by the operation of the transmission. And over the years, until today, the intention of the manufacturers has not changed. The difference is that currently a two-mass engine is installed on cars, regardless of the type of fuel used.

Dvamasa - why?

Usually the driver will know about the dual mass flywheel when it needs to be replaced. This moment is especially memorable because of the amount that has to be spent on a new item. Before you notice the symptoms of dual-mass flywheel damage, it's good to know a little more about this invention, which is very sensitive to the way you drive a car and modifications to improve its performance.The dual mass flywheel is part of the transmission. They are located between the main shaft and the gearbox.

The role of double mass in the car

The task of a dual-mass flywheel is to dampen vibrations arising from the torque generated during the combustion of the mixture and the work performed by the crank-piston system. The popular double mass is attached to the shaft on one side and the clutch and pressure plate on the other.

Detailed construction of a dual-mass flywheel

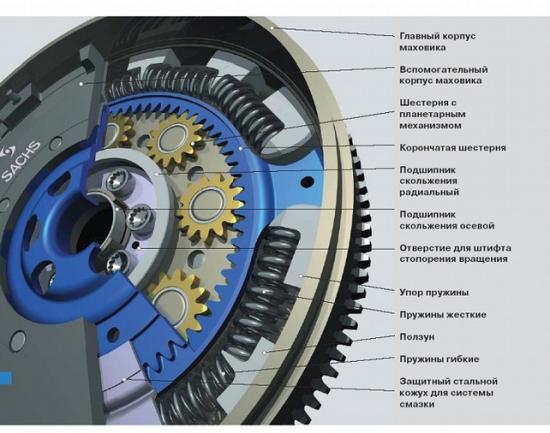

The most important elements of dual mass are:

- initial mass;

- secondary mass;

- sliding bearing;

- arc or leaf springs;

- leading plate;

- coating;

- slides.

Based on the details above, you can deduce where the name "Dual Mass Flywheel" comes from. All because of the two elements that largely make up the structure of this subnode, i.e. primary and secondary mass.

How dual mass works

The primary mass may have some inertia due to the moving assembly with the cover. The ability to rotate the secondary mass relative to the primary mass absorbs vibrations from the crankshaft to the spring system, which act as dampers. They are connected to each other in the company of lubrication, which causes additional vibration capture and prevents faster wear of metal elements. Thanks to this design, manufacturers of dual-mass flywheels have significantly reduced the level of vibration caused by the operation of the drive unit.

Symptoms of a damaged double mass - how to recognize them?

If you listen carefully for sounds coming from the drive system, you will be able to recognize component failures. The symptoms of a double mass suitable for regeneration or replacement are:

- jerks when starting off;

- noticeable vibrations and knocking when starting and stopping the engine;

- vibrations at rest when the unit is running;

- less comfortable gear shifting;

- knocking sound when accelerating from low rpm.

How to test the dual mass flywheel?

Are you wondering if double mass is good or is it suitable for repair? Check it! While driving, shift into 4th or 5th gear at low engine speeds and depress the accelerator pedal sharply. If during this procedure (in cars with manual and automatic transmission) you feel noises, knocks and increased vibrations, then you can almost be sure that the dual mass flywheel is not working.

Another way to check for symptoms of a damaged double mass is to visit a diagnostic service. Of course, this comes at a cost, but you will find out if the dual-mass flywheel is damaged and needs to be repaired. The service technician connects the diagnostic device to the vehicle and determines the degree of wear of this element.

Causes of failure of the dual-mass flywheel

In the case of a dual-mass flywheel (as well as other working parts), the driving style of the driver has the greatest influence on the service life. The transmission does not like fast acceleration from low revs. It is especially painful for him when the driver moves in higher gears, i.e.

In this situation, a certain amount of air-fuel mixture is supplied to the combustion chamber, which usually provides adequate acceleration. However, under the influence of a combination of high gear and low revs, most of the torque is absorbed by the dual-mass flywheel, which is unable to transfer it to the gearbox and wheels.

Another factor that equally strongly affects the wear of this element is pulling away, which is often accompanied by a loss of traction. The entire drive system suffers from this, especially the hinges and the double mass clutch. Also remember that you can not constantly drive at low engine speeds. Although economical in certain situations, this can have a negative effect on the dual mass flywheel.

What else affects the life of the double mass?

Symptoms of damage to a dual-mass flywheel can be noticed more quickly on modified vehicles. The manufacturer, anticipating the specific parameters of the engine, selects components for them, taking into account their durability. Of course, these are not contact values, but there is a certain margin.

The most popular way to increase power Chiptuning. Of course, performed by a reasonable tuner and a responsible driver, it will not have a drastic effect on the operation of a two-mass engine. More often than not, however, giving the user more power results in a more dynamic ride. This combination affects the faster operation of the transmission elements.

Regeneration of the dual-mass flywheel - does it make sense?

In many cases, it is possible to recover a damaged item. The process of restoring a dual-mass flywheel consists in disassembling the faulty assembly, replacing damaged springs, bearing discs or skids, grinding surfaces, turning and balancing the element. The mechanic also gets rid of the old grease by replacing it with new.

Whether regenerating a dual-mass flywheel makes sense depends on two factors:

- quality of repair;

- damage level.

Repair shops claim that the vast majority of components can be repaired this way. However, sometimes the level of defects is so severe that the only reasonable solution is to replace it with a new part. This prevents the introduction of a remanufactured component with very poor quality replacements. In this case, after a short time, there is a risk of damaging the double mass again and incurring costs. Look at the warranty period for such a service at a given institution. If this is a “guarantee until the gate and then we don’t know each other,” then don’t get involved in this matter.

Double mass replacement cost

When you decide on a new dual mass flywheel, keep in mind that this is not the cheapest item. Depending on the manufacturer of the car and components, the price can exceed 100 euros. At the same time, when replacing a dual-mass flywheel, it is worth looking at the condition of the clutch pressure and the quality of the clutch disc. It may turn out that it is best to replace both of these elements at the same time, so as not to risk another visit to the workshop in the near future.

Driving comfort is an extremely important issue for drivers nowadays. That is why dual-mass is present in almost every new car. Try to look after the transmission system so as not to expose yourself to a premature visit to the workshop.