Engine injectors

Content

The fuel injector (TF), or injector, refers to the details of the fuel injection system. It controls the dosage and supply of fuels and lubricants, followed by their spraying in the combustion chamber and combining with air into a single mixture.

TFs act as the main executive bodies associated with the injection system. Thanks to them, the fuel is sprayed into the smallest particles and enters the engine. Nozzles for any type of engine serve the same purpose, but differ in design and principle of operation.

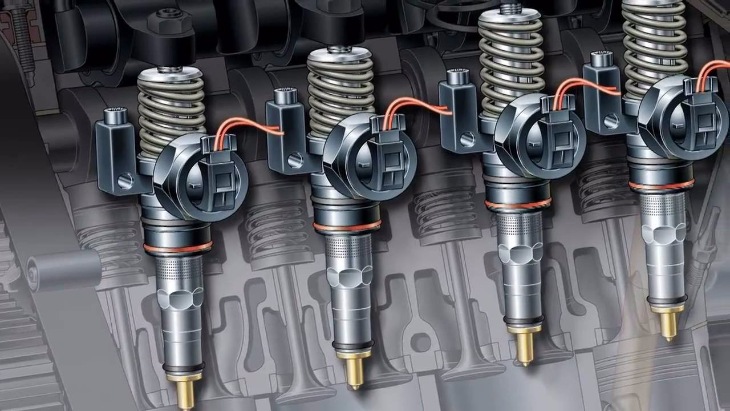

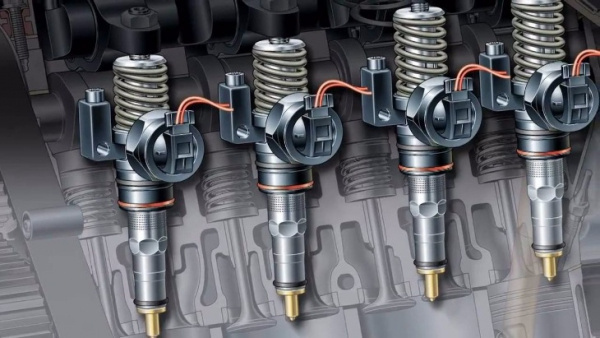

Fuel injectors

This type of product is characterized by individual production for a specific type of power unit. In other words, there is no universal model of this device, so it is impossible to rearrange them from a gasoline engine to a diesel one. As an exception, we can cite as an example hydromechanical models from BOSCH, installed on mechanical systems operating with continuous injection. They are widely used for various power units as an integral element of the K-Jetronic system, although they have various modifications that are not related to each other.

Location and principle of operation

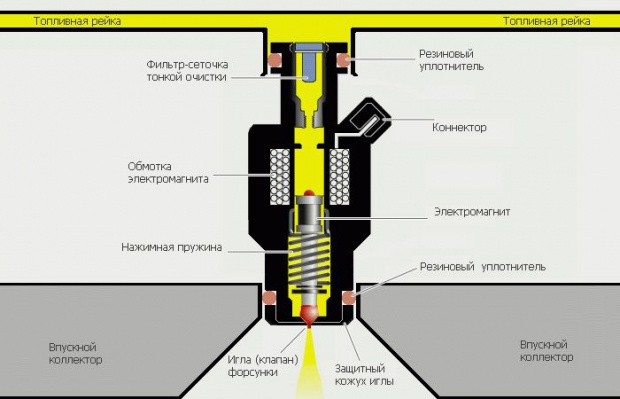

Schematically, the injector is a solenoid valve controlled by software. It ensures the supply of fuel to the cylinders in predetermined doses, and the installed injection system determines the type of products used.

Like a mouthpiece

Fuel is supplied to the nozzle under pressure. In this case, the engine control unit sends electrical impulses to the injector solenoid, which start the operation of the needle valve responsible for the state of the channel (open / closed). The amount of incoming fuel is determined by the duration of the incoming pulse, which affects the period the needle valve is open.

The location of the nozzles depends on the specific type of injection system:

• Center: located in front of the throttle valve in the intake manifold.

• Distributed: all cylinders correspond to a separate nozzle located at the base of the intake pipe and injecting fuel and lubricants.

• Direct - nozzles are located on top of the cylinder walls, providing injection directly into the combustion chamber.

Injectors for gasoline engines

Gasoline engines are equipped with the following types of injectors:

• Single point - fuel delivery located in front of the throttle.

• Multi-point: several nozzles located in front of the nozzles are responsible for supplying fuel and lubricants to the cylinders.

TFs provide the supply of gasoline to the combustion chamber of the power plant, while the design of such parts is non-separable and does not provide for repair. At a cost they are cheaper than those installed on diesel engines.

dirty injectors

As a part that ensures the normal operation of the fuel system of a car, injectors often fail due to contamination of the filter elements located in them with combustion products. Such deposits block the spray channels, which disrupts the operation of a key element - the needle valve and disrupts the supply of fuel to the combustion chamber.

Injectors for diesel engines

The correct operation of the fuel system of diesel engines is ensured by two types of nozzles installed on them:

• Electromagnetic, for the regulation of the rise and fall of the needle which is responsible for a special valve.

• Piezoelectric, hydraulically actuated.

The correct setting of the injectors, as well as the degree of their wear, affects the operation of the diesel engine, the power it produces and the amount of fuel consumed.

A car owner can notice a failure or malfunction of a diesel injector by a number of signs:

• Increased fuel consumption with normal traction.

• The car does not want to move and smokes.

• The car's engine vibrates.

Problems and malfunctions of engine injectors

To maintain the normal operation of the fuel system, it is necessary to periodically clean the nozzles. According to experts, the procedure should be carried out every 20-30 thousand kilometers, but in practice the need for such work arises after 10-15 thousand kilometers. This is due to poor fuel quality, poor road conditions and not always proper car care.

The most pressing problems with injectors of any kind include the appearance of deposits on the walls of parts, which are the result of using low-quality fuel. The consequence of this is the appearance of contamination in the flammable liquid supply system and the occurrence of interruptions in operation, loss of engine power, excessive consumption of fuels and lubricants.

The reasons that affect the operation of the injectors can be:

• Excessive sulfur content in fuels and lubricants.

• Corrosion of metal elements.

• Brings.

• Filters clogged.

• Incorrect installation.

• Exposure to high temperatures.

• Penetration of moisture and water.

An impending disaster can be identified by a number of signs:

• Occurrence of unplanned failures when starting the engine.

• Significant increase in fuel consumption compared to the nominal value.

• Appearance of black exhaust.

• The appearance of failures that violate the rhythm of the engine at idle.

How to clean nozzles

To solve the above problems, periodic flushing of the fuel injectors is required. To remove contaminants, ultrasonic cleaning is used, a special liquid is used, performing the procedure manually, or special additives are added to clean the injectors without disassembling the engine.

Fill the dump into the gas tank

The easiest and gentlest way to clean dirty nozzles. The principle of operation of the added composition is to constantly dissolve existing deposits in the injection system with its help, and also partially prevent their occurrence in the future.

flush the nozzle with additives

This method is good for new or low mileage vehicles. In this case, adding a flush to the fuel tank acts as a preventative measure to keep the machine's power plant and fuel system clean. For vehicles with heavily contaminated fuel systems, this method is not suitable, and in some cases can be harmful and exacerbate existing problems. With a large amount of pollution, the washed deposits enter the nozzles, clogging them even more.

Cleaning without dismantling the engine

Flushing of the TF without disassembling the engine is carried out by connecting the flushing unit directly to the engine. This approach allows you to wash off the accumulated dirt on the nozzles and the fuel rail. The engine starts at idle for half an hour, the mixture is supplied under pressure.

flushing nozzles with the device

This method is not suitable for heavily worn engines and is not suitable for vehicles with KE-Jetronik installed.

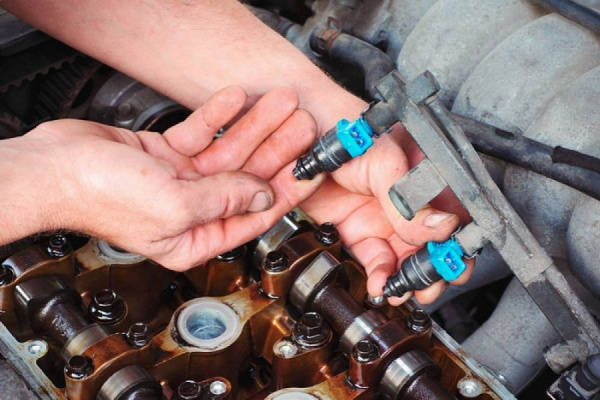

Cleaning with disassembly of nozzles

In case of severe contamination, the engine is disassembled on a special stand, the nozzles are removed and cleaned separately. Such manipulations also allow you to determine the presence of malfunctions in the operation of the injectors with their subsequent replacement.

removal and washing

Ultrasonic cleaning

The nozzles are cleaned in an ultrasonic bath for previously disassembled parts. The option is suitable for heavy dirt that cannot be removed with a cleaner.

Operations for cleaning nozzles without removing them from the engine cost the car owner an average of 15-20 US dollars. The cost of diagnostics with subsequent cleaning of the injector at an ultrasound scan or at a stand is about 4-6 USD. Comprehensive work on flushing and replacing individual parts allows you to ensure uninterrupted operation of the fuel system for another six months, adding 10-15 thousand km to the mileage.