Torsional vibration damper

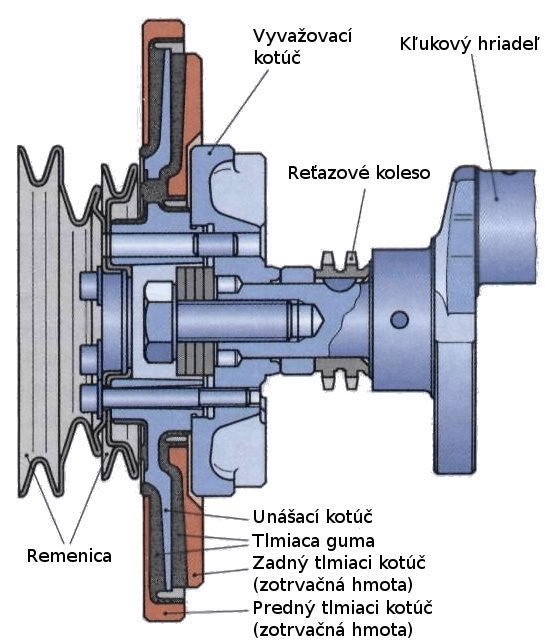

Torsional vibration dampers are designed to damp crankshaft vibrations that occur during combustion. They are located on the free end of the crankshaft along with the drive pulley of the engine accessories (alternator, air conditioning compressor, servo drive, etc.).

Torsional vibration dampers are designed to damp crankshaft vibrations that occur during combustion. They are located on the free end of the crankshaft along with the drive pulley of the engine accessories (alternator, air conditioning compressor, servo drive, etc.).

During the combustion of fuel, impact forces of different intensity and frequency act on the crankshaft, so that the crankshaft vibrates torsionally. If the oscillations induced in this way at certain so-called critical rotational speed correspond to the natural oscillations of the crankshaft, there is a so-called resonance, and the shaft can vibrate to such an extent that it breaks. It should be borne in mind that the method and intensity of vibrations is determined by the design and material of the shaft. To eliminate this unwanted vibration, a torsional vibration damper, usually located at the free end of the crankshaft, operates.

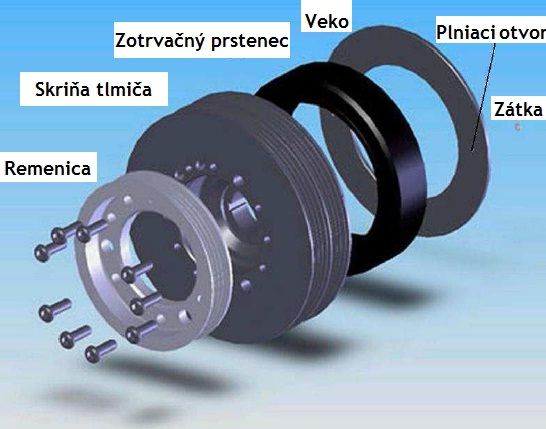

The damping masses (inertia) of the torsional vibration damper are elastically connected to the drive disc by a damping rubber ring. The drive disc is firmly attached to the crankshaft. If the crankshaft begins torsionally vibration, this vibration is damped by the inertia of the damping mass, which deforms the damping rubber. Instead of rubber, high-viscosity silicone oil is sometimes used, and the torsional vibration damper is then called viscous.