Auto generator. The device and how it works

Content

- Generator in car

- What is a car generator

- Why does a car need a generator?

- Drive and mount

- Device and design features

- The main parameters of the generator

- How the auto generator works

- What is a voltage regulator for?

- Harmful rules for operating the generator (according to Oster)

- How to test a car alternator

- Faulty car alternator

- Related videos

- Questions and answers:

Generator in car

The generator appeared in the automotive industry at the beginning of the 20th century along with the battery, which required constant recharging. These were huge DC nodes requiring constant maintenance. Modern generators have become compact, the high reliability of individual parts is due to the introduction of new production technologies. Next, we analyze the device, the principle of operation and typical generator malfunctions in more detail.

What is a car generator

A car generator is a unit that converts mechanical energy into electrical energy and performs the following functions:

- provides a constant and continuous battery charge when the engine is running;

- provides power to all systems during engine start, when the starter consumes a large amount of electricity.

The generator is installed in the engine compartment. Due to the brackets, it is attached to the engine block, driven by a drive belt from the crankshaft pulley. An electric generator is connected in an electrical circuit in parallel with the storage battery.

The battery is charged only when the generated electricity exceeds the battery voltage. The power of the generated current depends on the revolutions of the crankshaft, respectively, the voltage increases with the revolutions of the pulley with a geometric progression. To prevent overcharging, the generator is equipped with a voltage regulator that adjusts the amount of output voltage, providing 13.5-14.7V.

Why does a car need a generator?

In a modern car, almost every system is controlled by sensors that record their different modes of operation. If all these elements worked due to the battery charge, then the car would not even have time to warm up, as the battery is completely discharged.

So that during the operation of the motor, each system would not be powered by a battery, a generator is installed. It works exclusively when the internal combustion engine is on and is needed for:

- Recharge the battery;

- Provide sufficient energy for each unit of the machine's electrical system;

- In emergency mode or at maximum load, perform both functions - and feed the battery, and provide energy to the vehicle's electrical system.

It is necessary to recharge the battery, because when starting the motor, only the battery energy is used. To prevent the battery from discharging while driving, it is not recommended to turn on many energy consumers.

For example, in winter, some drivers turn on the car's climate system and glass heaters when warming up the cabin, and so that this process does not go boring, they also have a powerful audio system. As a result, the generator does not have time to generate so much energy and it is partially taken from the battery.

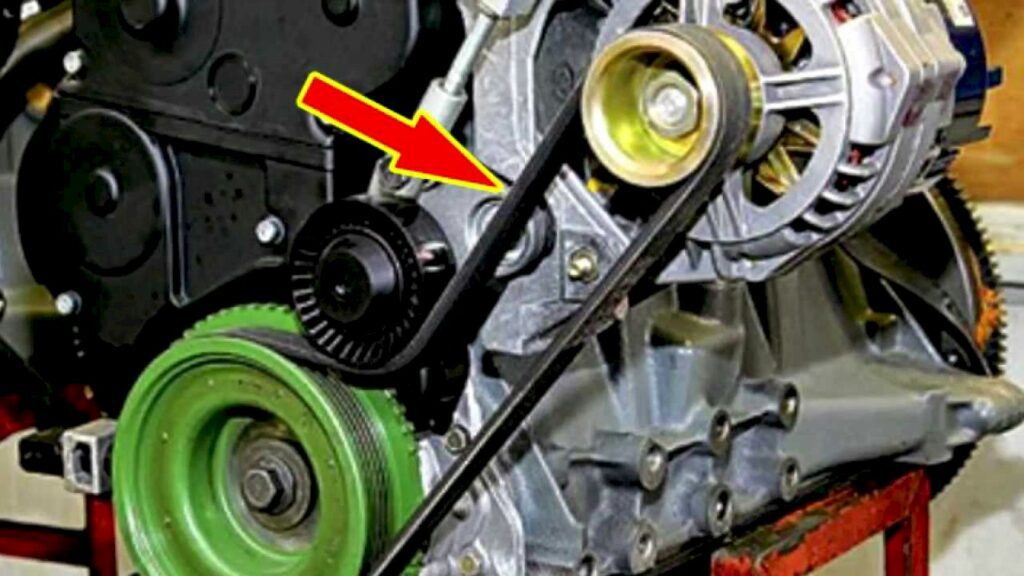

Drive and mount

This mechanism is driven by a belt drive. It is connected to the crankshaft pulley. Most often, the crankshaft pulley diameter is larger than that of the generator. Due to this, one revolution of the crank mechanism shaft corresponds to several revolutions of the generator shaft. Such dimensions allow the device to generate more energy for different consuming elements and systems.

The generator is mounted in close proximity to the crankshaft pulley. The tension of the drive belt in some car models is carried out by rollers. Budget cars have a simpler generator mount. It has a guide on which the device body is fixed with bolts. If the belt tension is loose (under loads it will slip on the pulley and squeak), then this can be corrected by moving the generator housing a little further from the crankshaft pulley and fix it.

Device and design features

Automotive generators perform the same function, work on the same principle, but differ in size, in the diagram of the implementation of the components, in the pulley, in the characteristics of rectifiers and voltage regulators, in the presence of cooling (liquid or air are often used on diesel engines). The generator consists of:

- body (front and back cover);

- stator;

- rotor;

- diode bridge;

- pulley;

- brush assembly;

- voltage regulator.

Chassis

The vast majority of generators have a housing consisting of two covers that are interconnected by studs and tightened with nuts. The performance of the part is made of alloy aluminum, which has a good heat sink and is not magnetized. The housing has ventilation openings for heat transfer.

Stator

It has a ring-shaped shape, installed inside the case. It is one of the main parts that serves to create alternating current due to the magnetic field of the rotor. The stator consists of a core, which is assembled from 36 plates. In the grooves of the core is a copper winding, which serves to generate current. Most often, the winding is three-phase, according to the type of connection:

- star - the ends of the winding are interconnected;

- triangle - the ends of the winding are output separately.

Rotor

Rotating do, the axis of which rotates on ball bearings of a closed type. An excitation winding is installed on the shaft, which serves to create a magnetic field for the stator. To ensure the correct direction of the magnetic field, two pole cores with six teeth for each are installed above the winding. Also, the rotor shaft is equipped with two copper rings, sometimes brass or steel, through which current flows from the battery to the excitation coil.

Diode bridge / rectifier block

It is also one of the main components, the task of which is to convert alternating current to direct, providing a stable charge of the car battery. The diode bridge consists of a positive and negative radiator strip, as well as diodes. Diodes are hermetically soldered into the bridge.

Current is supplied to the diode bridge from the stator winding, rectified and supplied to the battery through the output contact in the back cover.

Pulley

The pulley, through the drive belt, transmits torque to the generator from the crankshaft. The size of the pulley determines the gear ratio, the larger its diameter, the less energy is needed to rotate the generator. Modern cars are moving to a freewheel, the point of which is to smooth out oscillations in the rotation of the pulley, while maintaining the tension and integrity of the belt.

Brush assembly

On modern cars, brushes are combined in one node with a voltage regulator, they only change in assembly, since their service life is quite large. Brushes are used to transmit voltage to the contact rings of the rotor shaft. Graphite brushes are pressed by springs.

Voltage regulator

The semiconductor regulator ensures the maintenance of the required voltage in the given parameters. Located on the brush holder block or can be displayed separately.

The main parameters of the generator

The modification of the generator is matched to the parameters of the vehicle's on-board system. Here are the parameters taken into account when selecting an energy source:

- The voltage that the device produces is 12 V in the standard, and 24V for more powerful systems;

- The generated current should not be lower than that required for the car's electrical system;

- Current-speed characteristics is a parameter that determines the dependence of the current strength on the generator shaft speed;

- Efficiency - in most cases, the model produces an indicator of 50-60 percent.

These parameters must be taken into account when a vehicle is being upgraded. For example, if you install more powerful sound reinforcement equipment or an air conditioner in a car, the electrical system of the car will consume more energy than the generator can produce. For this reason, you should consult an auto electrician on how to choose the right power source.

How the auto generator works

The generator operation scheme is as follows: when the key is turned in the ignition switch, the power supply is turned on. The voltage from the battery is supplied to the regulator, which, in turn, transmits it to copper slip rings, the end consumer is the rotor excitation winding.

From the moment the engine crankshaft rotates, the rotor shaft begins to rotate through the belt drive, an electromagnetic field is created. The rotor generates an alternating current, when a certain speed is reached, the excitation winding is powered from the generator itself and not from the battery.

The alternating current then flows to the diode bridge, where the “equalization” process takes place. The voltage regulator monitors the operating mode of the rotor, if necessary, changes the voltage of the field winding. Thus, provided that the parts are in good condition, a stable current is supplied to the battery, providing the on-board network with the required voltage.

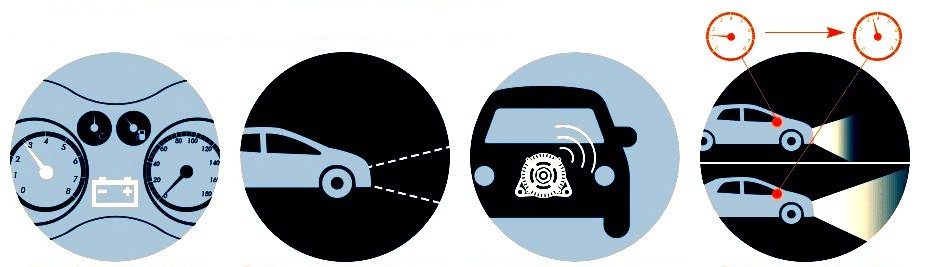

The battery indicator is displayed on the dashboard of more modern cars, which also indicates the status of the generator (it lights up when the belt breaks or reloads). Such cars as VAZ 2101-07, AZLK-2140, and other Soviet “equipment” have a dial indicator, ammeter or voltmeter, so you can always monitor the status of the generator.

What is a voltage regulator for?

Situation: when the engine is running, the battery charge decreases sharply, or a recharge occurs. First you need to check the battery, and if it is working, then the problem is in the voltage regulator. The regulator can be remote, or integrated into the brush assembly.

At high engine speeds, the voltage from the generator can increase to 16 volts, and this adversely affects the battery cells. The regulator “removes” the excess current, receiving it from the battery, and also regulates the voltage in the rotor.

Briefly about the charge that the generator should give:

Harmful rules for operating the generator (according to Oster)

The following are the steps from the rubric “how to kill a generator in two steps”:

- “reverse polarity” rule - swap the battery wires and you will arrange an unusual bright flash in the generator, as well as a light cloud coming from it. At the same time, you will feel an unforgettable acoustic pleasure, listening to clicks and hisses, as well as the incredible smell of burning wires, and most importantly, a 1-3 degree burn, depending on your ambitions. Such a “trick” partially disables the diode bridge, the stator and the regulator, fortunately, a car fire has a chance of 1: 1000. From the “side effects”, the instrument cluster, on-board computer, radio tape recorder and other components of the on-board network can be disabled. Dignity - mastered by beginners without long theories;

- washing rule - wash the power unit as often and thoroughly as possible, plenty of water and foam, especially on the alternator and starter. The main thing is that the flow of water abundantly flushes the generator from the inside, it is strictly forbidden to dry it, we immediately start the engine, turn on all the energy consumers and observe the effects. If not, repeat the procedure. Dignity - the burned "gene" will be clean;

- old-fashioned method - pulling the wire from the “+” terminal to check the charge on a running motor, this is the main rule! The probability of failure of all kinds of relays is 50:50, the main thing is to provide a lot of sparks for the effect, and also turn on everything that is powered by electricity;

- We “fly” through puddles - many do not even realize that they use this rule in the rain. The main thing is to always be sure that your car is beyond comparison with the water resistance of a submarine, the deeper the puddle, the brighter the effect. It is important to choose a speed at which more water enters the engine compartment, the main thing is to throw away all the plastic casings and protection! The main advantage is that the trick can be repeated wherever there is water (even streams and rivers) without leaving the car;

- “music lover” - you need to install the most expensive radio tape recorder, and preferably two, as many speakers as possible, a couple of dozen at least, amplifiers and a couple of subwoofers, turn on your favorite music at full volume with the engine running, if smoke does not come out from under the hood, but air remains clean - it means you have purchased too cheap equipment;

- “old battery” - the method requires some knowledge of physics, at least Ohm's law. We take the oldest battery, and the older, the more likely it will be a closed bank. Perhaps the battery will show signs of violent operation, it will certainly consume a wild amount of energy, but the operation of the injector will be unstable, and you can forget about the high beam. The main thing is to exploit the old battery more - the effect will not keep you waiting.

How to test a car alternator

Although the generator should be repaired by specialists, you can check it for performance yourself. On old cars, experienced motorists checked the generator for performance as follows.

Start the engine, turn on the headlights and, with the engine running, disconnect the negative battery terminal. When the generator is running, it generates electricity for all consumers, so that when the battery is disconnected, the engine will not stall. If the engine stalls, it means that the generator needs to be taken for repair or replaced (depending on the type of breakdown).

But on new cars it is better not to use this method. The reason is that modern alternators for such vehicles are designed for a constant load, part of which is compensated by constantly recharging the battery. If it is turned off while the generator is running, it may damage it.

The safest way to test the generator is with a multimeter. The principle of verification is as follows:

- With the engine off, the battery voltage is measured. With a good battery, this parameter should be 12.7 volts.

- The engine starts and all consumers turn off (cabin fan, headlights, glass heating, etc.)

- Once again, the multimeter probes are connected to the battery down conductors. Depending on the car model, the voltage at the terminals should be 13.8-14.8 volts.

- Consumers of electricity are turned on - as much as possible.

- The voltage is measured again. If the generator is working properly, this indicator will drop to 13.8-14 volts. A reading below this is a sign of alternator failure.

Faulty car alternator

The generator has mechanical and electrical faults.

Mechanical malfunctions:

- breakage of the drive belt - replacement is required;

- smoothing the pulley ribs, because of which the belt rotates;

- brush wear;

- damage to the generator housing;

- bearing failure.

Electric:

- wear of slip rings due to friction;

- failure of the voltage regulator;

- stator loop closure;

- burnout of rectifier bridge diodes;

- burnout of the final wires of the charge;

- burnout of the rotor winding.

Failure of any part of the generator leads to undercharging or vice versa. Most often, the voltage regulator and bearings fail, the drive belt changes according to the maintenance regulations.

By the way, if on occasion you want to install improved bearings and a regulator, pay attention to their characteristics, otherwise it is highly likely that replacing the part will not give the desired effect. All other breakdowns require the removal of the generator and its disassembly, which is best left to a specialist. The main thing to remember is that if you do not follow the rules according to Oster, then there is every chance for a long and trouble-free operation of the generator.

Here is a short video about the connection between the power of the generator and the battery:

Watch this video on YouTube

Difficulty starting the motor

Although the engine is solely powered by the battery to start, a difficult start may indicate either leakage current or the battery is not charging properly. It is worth considering that short-term trips will consume a lot of energy, and during this time the battery will not recover its charge.

If every day the car starts worse and worse, and the trips are long, then you should pay attention to the generator. But a generator malfunction can also be associated not only with undercharging, but also with overcharging the battery. In this case, it is necessary to replace the relay-regulator, which is responsible for maintaining a specific output voltage.

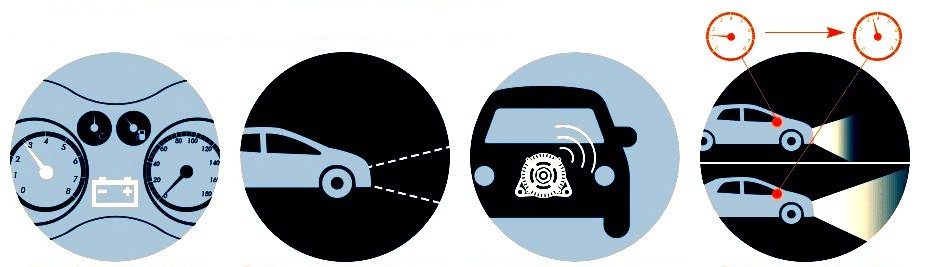

Dim or flickering headlights

During operation, the generator must fully provide energy to all consumers that are in the car (except for powerful external devices, the presence of which is not provided by the manufacturer). If during a trip the driver notices that the headlights have become dimmer or flickering, this is a symptom of a malfunctioning generator.

Such a generator can produce a normal charge, but it may not be able to cope with an increased load. A similar malfunction can be noticed by the flickering or dim light of the instrument panel backlight.

The icon on the dashboard is on

To warn the driver of insufficient charge and other problems associated with the power supply, manufacturers have placed an icon on the dashboard with a picture of the battery. If this icon lights up, it means that the car has a serious problem with electricity.

Depending on the condition and type of battery without recharging (only on battery capacity), the car is able to drive several tens of kilometers. On each battery, the manufacturer indicates how long the battery will last without recharging.

Even if all energy consumers are turned off, the battery will still be discharged, since electricity is needed to generate a spark in the cylinders (or heat the air in a diesel unit). When the battery icon lights up, you must immediately go to the nearest car service or call a tow truck (some types of batteries installed on modern cars cannot be restored after a deep discharge).

Drive belt whistles

Such a sound often appears immediately after starting the engine in wet weather or after overcoming a deep puddle. The reason for this effect is to loosen the alternator belt tension. If, after tightening, the belt began to whistle again over time, it is necessary to establish why it quickly loosens.

The alternator belt must be well tensioned, because when different consumers are turned on, it creates more resistance to the rotation of the shaft (in order to generate more electricity, as in a conventional dynamo).

In some modern cars, the belt tension is provided by an automatic tensioner. In the design of simpler cars, this element is absent, and the belt tension must be done manually.

Belt overheats or breaks

Heat or premature failure of the drive belt indicates that it is being overstressed. Of course, the driver does not need to check the temperature of the generator drive every time, but if the smell of burnt rubber is clearly audible and a slight smoke appears in the engine compartment, it is necessary to check the condition of the drive belt.

Often, the belt wears out prematurely due to the failure of the generator shaft bearing or tension rollers, if they are in the design. A break in the alternator belt in some cases can lead to disruption of the valve timing due to the fact that the piece has fallen under the timing belt.

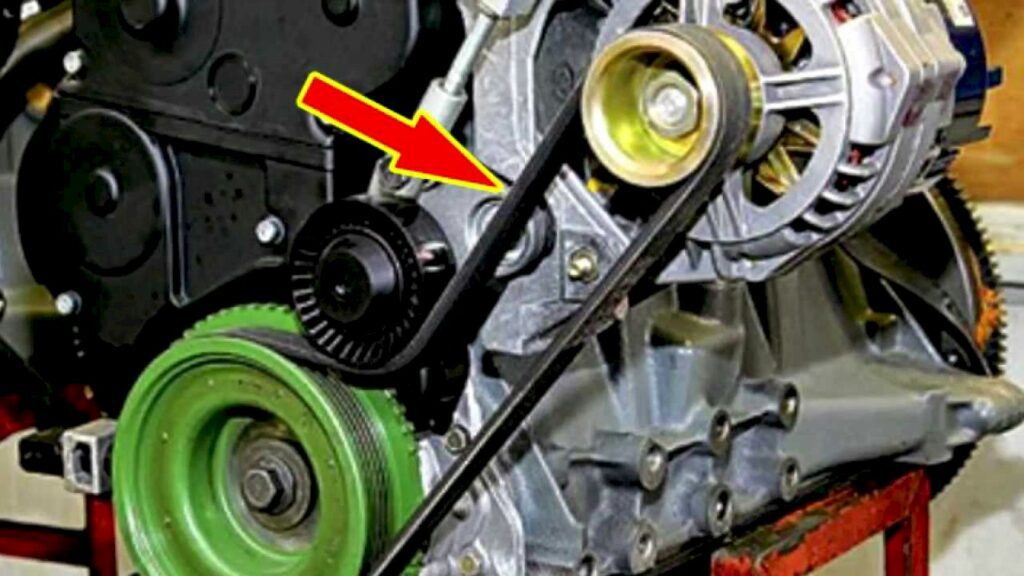

Ringing or rustling sound from under the hood

Each generator is equipped with rolling bearings that provide a constant distance between the rotor and stator windings. After starting the engine, the bearings are constantly in rotation, but unlike many parts of the internal combustion engine, they do not receive lubrication. Because of this, they cool worse.

Due to constant heat and mechanical stress (the belt must be under tight tension), bearings can lose lubrication and break down quickly. If during operation of the generator or with an increase in load, ringing or metallic rustling occurs, then the bearings should be replaced. In some modifications of the generators there is an overrunning clutch, which smooths out torsional vibrations. This mechanism also often fails. The alternator will need to be removed to replace the bearings or freewheel.

electric hum

This sound is similar to the sound of large electric motors, such as those installed on trolleybuses. When such a sound appears, it is necessary to dismantle the generator and check the condition of its windings. Basically, it appears when the winding in the stator closes.

Related videos

In conclusion - a detailed description of the principle of operation of a car generator:

Watch this video on YouTube

Questions and answers:

What is a generator in a car for? This mechanism ensures the generation of electricity so that the battery reserve is not wasted. A generator converts mechanical energy into electricity.

What powers the generator in the car? While the engine is running, the generator generates electricity to recharge the battery and power all electrical equipment in the vehicle. Its capacity depends on the number of consumers.

2 comment

goose

HARMFUL RULES OF OPERATION OF THE GENERATOR (ON OESTER) amused))))

whybitchcry

thanks, it was fun to read