Hydropneumatic suspension - what is it and how does it work?

Content

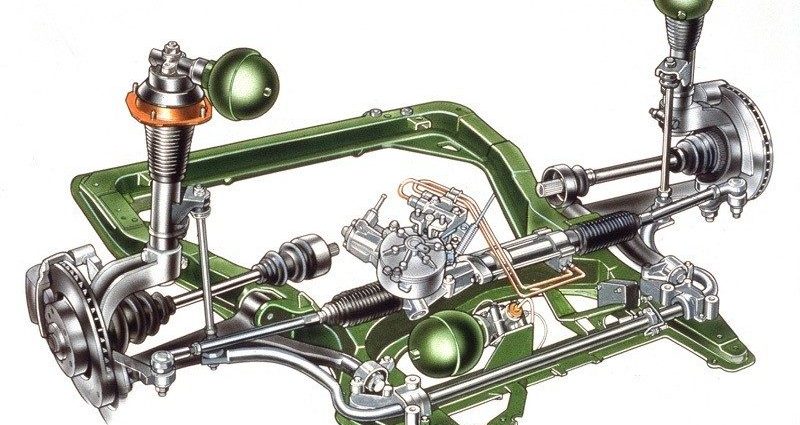

This is a type of suspension that is used in mid to high end vehicles, mostly branded by Citroen, but also in vehicles licensed by Rolls-Royce. The most characteristic feature of the hydropneumatic suspension is the absence of shock absorbers, since in its case the role of the spring element is performed by a compressed gas, which is nitrogen. Thanks to this suspension system, a constant ground clearance of the car is ensured, regardless of its load, which in turn results in a more stable behavior of the car on the road.

Since when has hydropneumatic suspension been used?

Hydropneumatic suspension is nothing new as it has been in use for over 60 years. The first model with such a suspension was Citroen BL15 Six H since 1954, the more recognizable the model is a year younger DS 19.

Hydropneumatic suspension - what breaks most often?

The most common malfunction is the stiffness of the suspension, i.e. no suspension. The reason may be, among other things, high wear of the seals in the suspension cylinders or an internal leak of the clearance correctors (regulators). The so-called diaphragm of the elastic element, also called the diaphragm pressure accumulator. Operating a vehicle with a damaged hydraulic accumulator usually results in premature wear of the pump due to its forced operation under load. The mechanical elements of the suspension are also damaged, especially bearings, metal-rubber bushings and hinges.

How to control?

The biggest problem in diagnosing the diaphragm of an elastic element is that the deformation of the latter is not visible. The actual state of affairs can only be determined on the basis of the readings of specialized diagnostic devices. They are used to determine the current nitrogen pressure value. With this data, it can be determined whether the pressure accumulator can be regenerated or should be replaced with a new one. Damage to metal or flexible pipes can also cause failure of the diaphragm of the elastic element. In the case of the former, first of all, check their tightness, and secondly, by checking the clamps. In addition to checking the cables, it is necessary to assess the technical condition of the dust covers with clips. Damage to guards can also lead to leaks. Fluid leaks to the outside can be seen by a bright green color (when using mineral oil in the hydraulic system).

Added by: 3 years ago,

a photo: AutoCenter