Cylinder head. Purpose and device

A modern internal combustion engine is a very complex unit, which includes a large number of components and parts. The key component of the internal combustion engine is the cylinder head (cylinder head). The cylinder head, or simply the head, serves as a kind of cover that closes the top of the internal combustion engine cylinders. However, this is far from the only functional purpose of the head. The cylinder head has a rather complex design, and its condition is critical for the normal operation of the internal combustion engine.

Every motorist should understand the device of the head and understand how this element functions.

Cylinder heads are produced by casting from alloyed cast iron or aluminum-based alloys. Aluminum alloy products are not as strong as cast iron, but they are lighter and less prone to corrosion, which is why they are used in the internal combustion engines of most passenger cars.

To eliminate the residual stress of the metal, the part is processed using a special technology. followed by milling and drilling.

Depending on the configuration of the internal combustion engine (arrangement of cylinders, crankshaft and camshafts), it may have a different number of cylinder heads. In a single-row unit, there is one head, in internal combustion engines of another type, for example, a V-shaped or W-shaped, there may be two. Large engines usually have separate heads for each cylinder.

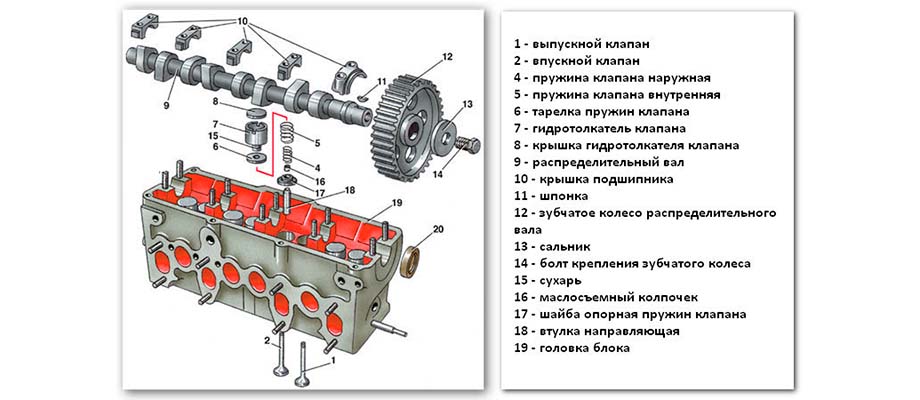

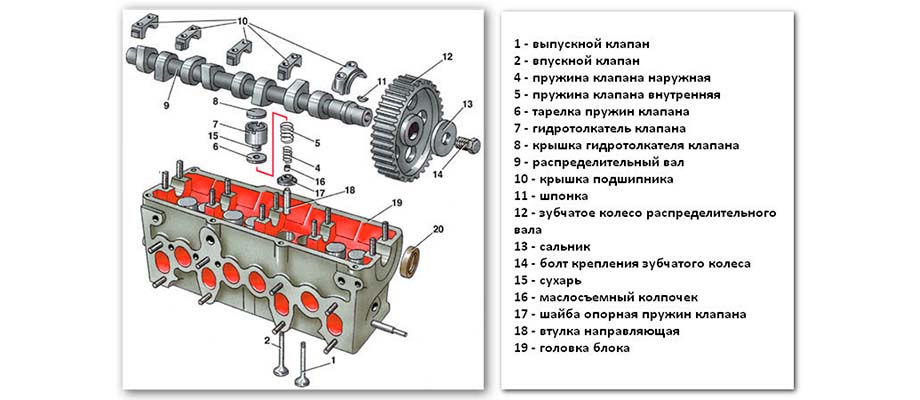

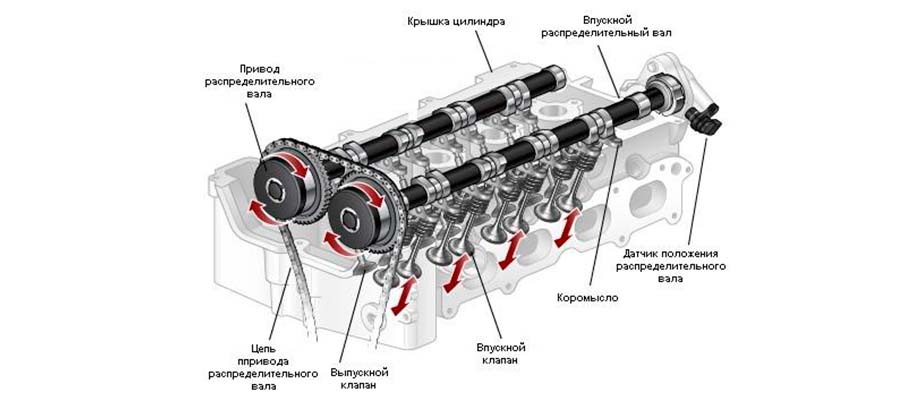

The design of the cylinder head also differs depending on the number and location of camshafts. Camshafts can be mounted in an additional compartment of the head, and can be installed in the cylinder block.

Other design features are possible, which depend on the number and arrangement of cylinders and valves, the shape and volume of the combustion chambers, the location of candles or nozzles.

In ICE with a lower valve arrangement, the head has a much simpler device. It has only antifreeze circulation channels, seats for spark plugs and fasteners. However, such units have low efficiency and have not been used in the automotive industry for a long time, although they can still be found in special equipment.

The cylinder head, in accordance with its name, is located at the top of the internal combustion engine. In fact, this is a housing in which the parts of the gas distribution mechanism (timing) are mounted, which controls the intake of the air-fuel mixture into the cylinders and the exhaust gases. The top of the combustion chambers are located in the head. It has threaded holes for screwing in spark plugs and injectors, as well as holes for connecting the intake and exhaust manifolds.

For the circulation of the coolant, special channels (the so-called cooling jacket) are used. Lubrication is supplied through oil channels.

In addition, there are seats for valves with springs and actuators. In the simplest case, there are two valves per cylinder (inlet and outlet), but there may be more. Additional inlet valves make it possible to increase the total cross-sectional area, as well as reduce dynamic loads. And with additional exhaust valves, heat dissipation can be improved.

The valve seat (seat), made of bronze, cast iron or heat-resistant steel, is pressed into the cylinder head housing or can be made in the head itself.

Valve guides provide precise seating. The material for their manufacture can be cast iron, bronze, cermet.

The valve head has a tapered chamfer made at an angle of 30 or 45 degrees. This chamfer is the working surface of the valve and is adjacent to the chamfer of the valve seat. Both bevels are carefully machined and lapped for a snug fit.

For reliable closing of the valve, a spring is used, which is made of alloy steel with subsequent special processing. The value of its preliminary tightening significantly affects the parameters of the internal combustion engine.

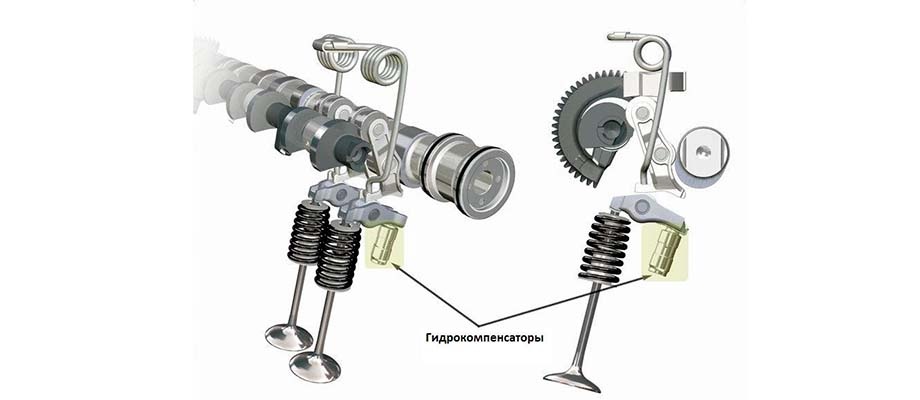

Controls the opening/closing of the camshaft valves. It has two cams for each cylinder (one for the intake, the other for the exhaust valve). Although other options are possible, including the presence of two camshafts, one of which controls the intake, the other controls the exhaust. In the internal combustion engines of modern passenger cars, it is most often used exactly two camshafts mounted on top, and the number of valves is 4 for each cylinder.

As a drive mechanism for controlling valves, levers (rocker arms, rockers) or pushers in the form of short cylinders are used. In the latter version, the gap in the drive is automatically adjusted using hydraulic compensators, which improves their quality and extends their service life.

The lower surface of the cylinder head, which is adjacent to the cylinder block, is made even and carefully processed. To prevent the ingress of antifreeze into the lubrication system or engine oil into the cooling system, as well as the penetration of these working fluids into the combustion chamber, a special gasket is installed between the head and the cylinder block during installation. It can be made of asbestos-rubber composite material (paronite), copper or steel with polymer interlayers. Such a gasket provides a high degree of tightness, prevents mixing of the working fluids of lubrication and cooling systems, and isolates the cylinders from each other.

The head is attached to the cylinder block with bolts or studs with nuts. The tightening of the bolts must be approached very responsibly. It should be produced in strict accordance with the instructions of the automaker according to a certain scheme, which may differ for different internal combustion engines. Be sure to use a torque wrench and observe the specified tightening torque, which must be indicated in the repair instructions.

Failure to comply with the procedure will lead to a violation of the tightness, the release of gases through the joint, a decrease in compression in the cylinders, and a violation of the isolation from each other of the channels of the lubrication and cooling systems. All this will be manifested by the unstable operation of the internal combustion engine, loss of power, excessive fuel consumption. At a minimum, you will have to change the gasket, engine oil and antifreeze with flushing systems. More serious troubles are possible, up to the need for a serious repair of the internal combustion engine.

it must be remembered that the cylinder head gasket is not suitable for reinstallation. If the head is removed, the gasket must be replaced, regardless of its condition. The same applies to the mounting bolts.

From above, the cylinder head is closed with a protective cover (it is also called a valve cover) with a rubber seal. It can be made of sheet steel, aluminum or plastic. The cap usually has a neck for pouring engine oil. Here it is also necessary to observe certain tightening torques when tightening the fastening bolts and change the sealing rubber each time the cover is opened.

The issues of prevention, diagnosis, repair and replacement of the cylinder head should be taken as seriously as possible, since this is a critical element of the internal combustion engine, which, moreover, is subjected to very significant mechanical and thermal loads.

Problems sooner or later arise even with proper operation of the car. Accelerate the appearance of malfunctions in the engine - and the head in particular - the following factors:

- ignoring the periodic shift;

- the use of low-quality lubricants or oils that do not meet the requirements for this internal combustion engine;

- use of poor quality fuel;

- clogged filters (air, oil);

- prolonged absence of routine maintenance;

- sharp driving style, abuse of high speeds;

- faulty or unregulated injection system;

- unsatisfactory condition of the cooling system and, as a result, overheating of the internal combustion engine.

The breakdown of the cylinder head gasket and other related problems have already been mentioned above. You can read more about this in a separate one. Other possible head failures:

- cracked valve seats;

- worn valve guides;

- broken camshaft seats;

- damaged fasteners or threads;

- cracks directly in the cylinder head housing.

Seats and guide bushings can be replaced, but this must be done using a special technology using special equipment. Attempts to make such repairs in a garage environment will most likely lead to the need for a complete head change. On your own, you can try to clean and grind the chamfers of the seats, while not forgetting that they must fit snugly against the mating chamfers of the valves.

To restore worn beds under the camshaft, bronze repair bushings are used.

If the thread in the candle socket is broken, you can install a screwdriver. Repair studs are used instead of damaged fasteners.

Cracks in the head housing can be tried to be welded if they are not at the gas joints. It is pointless to use tools such as cold welding, since they have a different coefficient of thermal expansion and simply crack very quickly. The use of welding to eliminate cracks passing through the gas joint is impractical - in this case, it is better to replace the head.

Together with the head, it is imperative to change its gasket, as well as the rubber seal of the cover.

When troubleshooting the cylinder head, do not forget to also diagnose the timing parts installed in it - valves, springs, rocker arms, rockers, pushers and, of course, the camshaft. If you need to purchase new spare parts to replace worn ones, you can do it in the online store.

It is more convenient and easier to purchase and mount the cylinder head assembly when the parts of the gas distribution mechanism (camshaft, valves with springs and actuators, etc.) are already installed in it. This will eliminate the need for fitting and adjustment, which will be required if the timing components from the old cylinder head are installed in the new head housing.