Characteristics of Maz 525

Consider the predecessor of the BelAZ series - MAZ-525.

The predecessor of the BelAZ series - MAZ-525

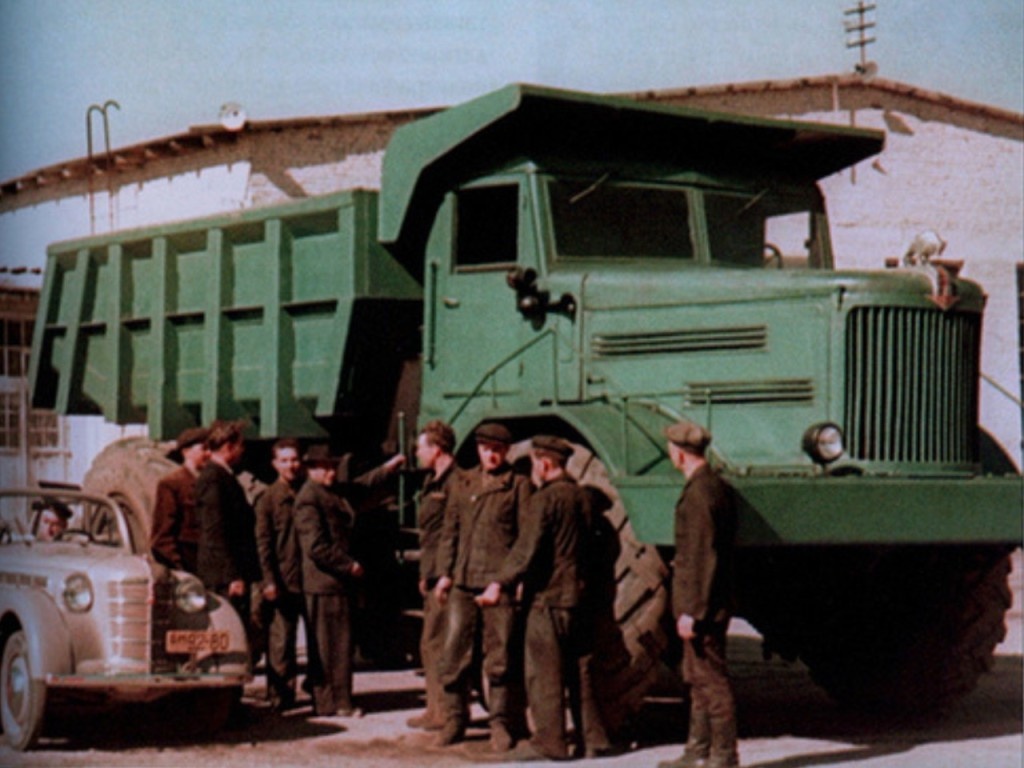

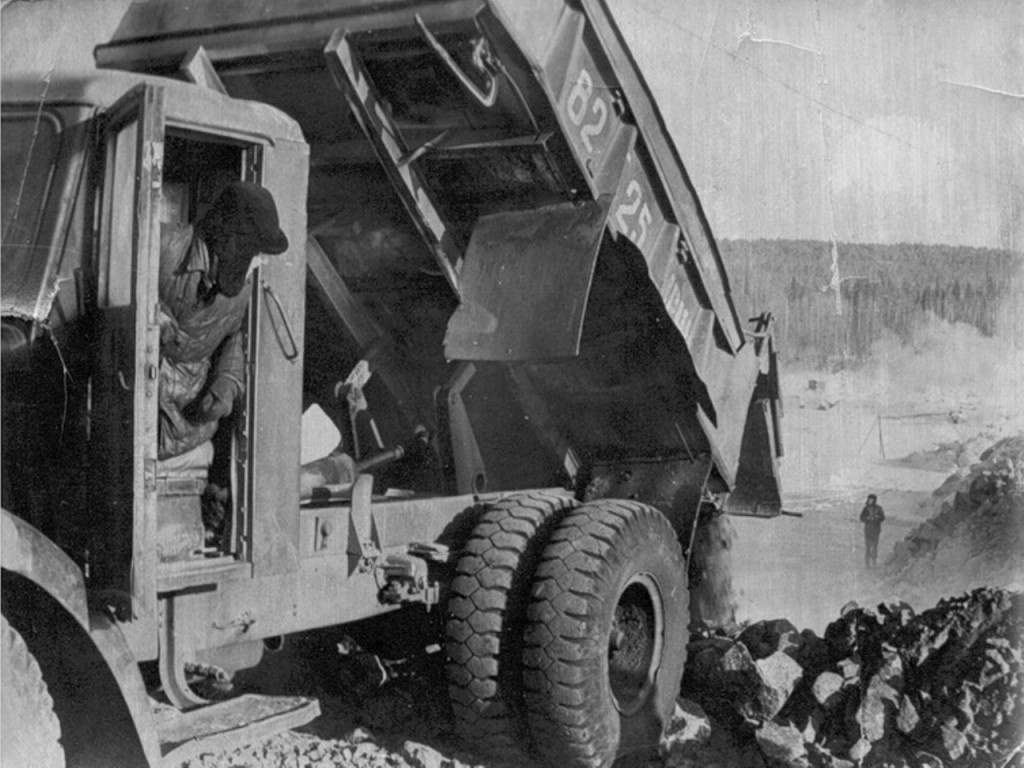

Serial mining dump truck MAZ-525 (1951-1959 - MAZ-525; 1959-1965 - BelAZ-525). The reason for the appearance of the 25-ton mining truck is the need for a technique capable of delivering granite blocks from quarries for the construction of dams. The MAZ-205 that existed at that time was not suitable for this purpose due to its low carrying capacity. A power reduction was installed on the car from 450 to 300 hp. 12-cylinder diesel tank D-12A. The rear axle, unlike the front axle, was rigidly attached to the frame, without springs, so no suspension could withstand the shock loads that occur when the dump truck is loaded with six cubic meters of paving stones (by the way).

To absorb the shocks of the transported cargo, the bottom was made double, from steel sheets with an oak joint between them. The load was transferred directly to the frame through six rubber pads. Huge wheels with a tire diameter of 172 centimeters served as the main shock absorber. The appearance of the car has undergone a number of changes in the mass production process. If in the first sample the engine hood at the base was equal to the width of the cab, then it became much narrower - to save metal. The contact oil-air filter, which did not fit under the hood, was placed first on the left, then on the right. Experience in dusty quarries suggested a solution: install two filters.

For the safety of the mechanics who serviced the diesel of this tall car, protection was first mounted on the sides of the hood (in the photo on the left), a year later it was abandoned. The number of vertical body stiffeners has been changed from seven to six. The chrome-plated figure of a bison, which was placed on the hoods of the first MAZ-525, was later divided into two "boots" - these bas-reliefs were attached to the sides of the hood, and even then not always. To date, the only dump truck that has survived in Russia is installed as a monument near the Krasnoyarsk hydroelectric power station. During the production of cars at the Belarusian Automobile Plant, the bison disappeared from the hood, and the inscriptions “BelAZ” appeared in its place.

In 1959, in Zhodino, an attempt was made to create a MAZ-525A saddle to work as part of a road train with a BelAZ-5271 tipper semi-trailer of its own design, designed for 45 tons of rock or earth. However, the experience was not successful, and the semi-trailer went into series only in 1962 with a more powerful BelAZ-540A tractor. A year after the start of production of the MAZ-525 mining dump truck, the MAZ-E-525D truck tractor created on its basis rolled out of the gates of the Minsk Automobile Plant. It was designed to work in conjunction with a 15-cubic-meter D-189 scraper, which it could handle only when transporting goods and driving empty, and when filling the body, a pusher was attached to the road train - the same MAZ .-. E-525D with ballast on the rear axle.

This was necessary, since filling the scraper required 600 hp from the tractor, while the power of the MAZ was only 300 hp. And yet, the need for a pusher at this stage cannot be considered a negative factor, since in terms of fuel consumption, servicing the scraper with two machines was more efficient than with one - twice as much power. After all, the pusher worked not with one, but with several scrapers at once, and the greater the distance of cargo transportation, the more scrapers one pusher could take, and the greater the efficiency of their use.

The maximum speed of the tractor with a fully loaded scraper was 28 km/h. It had dimensions of 6730x3210x3400 mm and a wheelbase of 4000 mm, which is 780 mm less than that of the dump truck on the chassis of which it was built. Directly behind the MAZ-E-525D cab, an engine-driven winch with a pulling force of up to 3500 kilograms was installed to control the scraper. In 1952, thanks to the efforts of the Mining Institute of the Academy of Sciences of the Ukrainian SSR, the Kharkov trolleybus depot and the Soyuznerud trust, a new type of transport was born. On the chassis of the MAZ-205 and YaAZ-210E dump trucks, and two years later, wheeled electric dump trucks were created on the twenty-five-ton MAZ-525.

The trolleybus on the MAZ-525 racing chassis was equipped with two trolleybus electric motors of the DK-202 type with a total power of 172 kW, controlled by a controller and four contact panels of the TP-18 or TP-19 type. The electric motors also powered the power steering and body lift. The transmission of electrical energy from the power plant to the electric motors of the cars was carried out in the same way as with ordinary trolleybuses: cables were laid along the route of their work, which touched electric dump trucks with two roof arches installed on them. The work of drivers on such machines was easier than on traditional dump trucks.

MAZ-525 dump truck: specifications

The post-war development of Soviet industry led to a sharp increase in the extraction of minerals, which were no longer able to be removed from the crankcase by ordinary dump trucks. After all, the capacity of mass-produced bodies at the beginning of the first post-war decade MAZ-205 and YaAZ-210E was 3,6 and 8 cubic meters, respectively, and the carrying capacity did not exceed 6 and 10 tons, and the mining industry needed a dump truck almost twice as many of these figures! The development and production of such a machine was entrusted to the Minsk Automobile Plant.

Such a difficult task fell on the shoulders of Boris Lvovich Shaposhnik, the future head of the famous SKB MAZ, where multi-axle missile carriers were created; by that time he had already worked as the chief designer, first at the ZIS, and then at the Novosibirsk Automobile Plant, the construction of which began in 1945, but even before commissioning he was transferred to another department. Shaposhnik arrived at the Minsk Automobile Plant along with several other designers from Novosibirsk in November 1949, taking the position of head of the plant's design bureau (KEO). The mentioned object was the future MAZ-525 quarry. For the domestic auto industry, this was a fundamentally new type of dump truck - nothing like this had ever been produced in our country before! And still

(carrying capacity 25 tons, gross weight 49,5 tons, body volume 14,3 cubic meters), had a number of technical solutions that were progressive for that time. For example, for the first time in our country, the MAZ-525 used a power steering and planetary gearboxes built into the wheel hubs. The engine delivered from Barnaul with 12 V-shaped cylinders developed 300 hp, the clutch was double-disk and combined with a hydraulic clutch that protected the transmission, and the diameter of the wheels almost exceeded the height of an adult!

Of course, by today's standards, the body capacity of the first Soviet mining dump truck MAZ-525 is not impressive: conventional dump trucks currently being produced, designed for driving on public roads, carry about the same amount of cargo on board. By the standards of the middle of the last century, the transfer of more than 14 "cubes" in one flight was considered a great achievement! For comparison: at that time, the YaAZ-210E, the largest domestic road dump truck, had a body volume that was six “cubes” less.

Shortly after the start of mass production in 1951, several changes were made to the appearance of the quarry: the semi-circular radiator lining was replaced with a rectangular one, the width of the hood was reduced at the point of its interface with the cab, and the small safety rails on the front fenders were removed. It is interesting that in 1954 a dump truck modification appeared with two trolleybus engines installed under the hood with a total power of 234 hp and a pantograph mounted on the cab roof. Although this development did not become standard, it seemed very relevant: the 39-liter diesel of the standard model was voracious, consuming 135 liters of diesel fuel per 100 kilometers even in ideal conditions.

In total, more than 1959 MAZ-800s were manufactured at the Minsk Automobile Plant until 525, after which their production was transferred to the city of Zhodino to the newly opened Belarusian Automobile Plant.

Became BelAZ

The plant, which today produces giant dump trucks, did not arise from scratch: it was created on the basis of the Zhodino Mechanical Plant, which produced road and evacuation vehicles. The resolution of the Central Committee of the CPSU and the Council of Ministers of the USSR on changing its name to the Belarusian Automobile Plant is dated April 17, 1958. In August, Nikolai Ivanovich Derevyanko, who previously worked as the deputy director of MAZ, became the announcer of the newly formed company.

The team headed by him was given the task of not only organizing the rapid production of the MAZ-525 necessary for the country, but also creating an assembly line for this - mining dump trucks using such a machine have not yet been produced by anyone in the world before.

The first Zhodino MAZ-525 from the components supplied by Minsk was assembled on November 1, 1958, and this despite the fact that many pieces of equipment had not yet been put into operation. But already in October 1960, having debugged the conveyor line, launched its own production of presses and welding, and also mastered the manufacture of the main components and assemblies, the Belarusian Automobile Plant handed over the thousandth MAZ-525 to customers.

The first domestic mining dump truck became the basis for the development of truck tractors on its basis. First, in 1952, the MAZ-E-525D appeared, designed to tow a 15-cc D-189 scraper, and already the Belarusian Automobile Plant experimented with the MAZ-525, capable of towing a single-axle dump semi-trailer. trailer - a trailer designed to carry up to 40 tons of bulk cargo. But neither one nor the other was widely used, mainly due to insufficient engine power (for example, when pouring the body, even the scraper was supposed to be pushed by a pusher car, the same MAZ-525 with a mounted ballast in the frame). The base dump truck had a number of significant drawbacks. First of all, it's over-engineered, too much metallic, inefficient transmission, low speed and no suspension rear axle. Therefore, already in 1960, the designers of the Belarusian Automobile Plant began designing a fundamentally new BelAZ-540 mining dump truck, which became the ancestor of a large family of Zhodino giant cars under the BelAZ brand. He replaced the MAZ-525 on the transporter, the production of which was curtailed in 1965.