Characteristics of engine oils

Content

Characteristics of engine oils show how the oil behaves in different temperature and load conditions, and thereby help the car owner to correctly select the lubricating fluid for the internal combustion engine. So, when choosing, it is useful to pay attention not only to the marking (namely, the viscosity and tolerances of car manufacturers), but also the technical characteristics of motor oils, such as kinematic and dynamic viscosity, base number, sulfate ash content, volatility and others. For most car owners, these indicators do not say anything at all. A In fact, they hide the quality of the oil, its behavior under load and other operational data.

So, you will learn in detail about the following parameters:

- Kinematic viscosity;

- Dynamic viscosity;

- Viscosity index;

- volatility;

- coking capacity;

- sulfate ash content;

- alkaline number;

- Density;

- Flash point;

- pour point;

- Additives;

- Life time.

The main characteristics of motor oils

Now let's move on to the physical and chemical parameters that characterize all engine oils.

Viscosity is the main property, due to which the ability to use the product in various types of internal combustion engines is determined. It can be expressed in units of kinematic, dynamic, conditional and specific viscosity. The degree of ductility of the motor material is determined by two indicators - kinematic and dynamic viscosities. These parameters, along with sulfate ash content, base number and viscosity index, are the main indicators of the quality of motor oils.

Kinematic viscosity

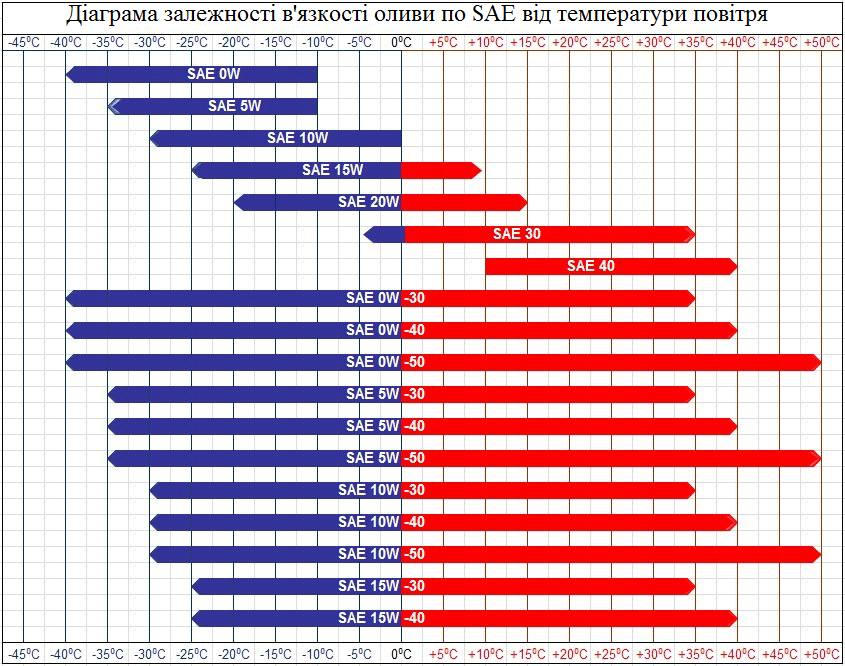

Graph of the dependence of viscosity on engine oil temperature

Kinematic viscosity (high temperature) is the basic operating parameter for all types of oils. It is the ratio of dynamic viscosity to the density of a liquid at the same temperature. Kinematic viscosity does not affect the condition of the oil, it determines the characteristics of the temperature data. this indicator characterizes the internal friction of the composition or its resistance to its own flow. Describes the fluidity of the oil at operating temperatures of +100°C and +40°C. Units of measurement - mm² / s (centiStokes, cSt).

In simple terms, this indicator shows the viscosity of the oil from temperature and allows you to estimate how quickly it will thicken when the temperature drops. After all the less the oil changes its viscosity with a change in temperature, the higher the quality of the oil.

Dynamic viscosity

The dynamic viscosity of the oil (absolute) shows the resistance force of the oily fluid that occurs during the movement of two layers of oil, 1 cm apart from each other, moving at a speed of 1 cm / s. Dynamic viscosity is the product of the kinematic viscosity of the oil and its density. The units of this value are Pascal seconds.

Simply put, it shows the effect of low temperature on the starting resistance of an internal combustion engine. And the lower the dynamic and kinematic viscosity at low temperatures, the easier it will be for the lubrication system to pump oil in cold weather, and for the starter to turn the ICE flywheel during a cold start. The viscosity index of the engine oil is also of great importance.

Viscosity index

The rate of decrease in kinematic viscosity with increasing temperature is characterized by viscosity index oils. The viscosity index evaluates the suitability of oils for given operating conditions. in order to determine the viscosity index, compare the viscosity of the oil at different temperatures. The higher it is, the less the viscosity depends on temperature, and hence the better its quality. In a nutshell, The viscosity index indicates the "degree of thinning" of the oil.. This is a dimensionless quantity, i.e. is not measured in any units - it's just a number.

The lower the index engine oil viscosity the more the oil thins, i.e. the thickness of the oil film becomes very small (due to which there is increased wear). The higher the index engine oil viscosity, less oil thins, i.e. the thickness of the oil film necessary to protect the rubbing surfaces is provided.

Oils with a high index ensure the performance of the internal combustion engine in a wider temperature range (environment). Consequently, an easier start-up of the internal combustion engine at low temperatures and a sufficient thickness of the oil film (and hence the protection of the internal combustion engine from wear) at high temperatures are provided.

High-quality mineral motor oils usually have a viscosity index of 120-140, semi-synthetic 130-150, synthetic 140-170. This value depends on the application in the composition of hydrocarbons and the treatment depth of the fractions.

A balance is needed here, and when choosing, it is worth considering the requirements of the motor manufacturer and the condition of the power unit. However, the higher the viscosity index, the wider the temperature range that the oil can be used.

Evaporation

Evaporation (also called volatility or waste) characterizes the amount of mass of the lubricating fluid that evaporated within one hour at its temperature of +245,2 ° C and an operating pressure of 20 mm. rt. Art. (± 0,2). Conforms to the ACEA standard. Measured as a percentage of the total mass, [%]. It is carried out using a special Noack apparatus according to ASTM D5800; DIN 51581.

Than higher oil viscosity, the it has a lower volatility according to Noak. Specific volatility values depend on the type of base oil, i.e. set by the manufacturer. It is believed that good volatility is in the range up to 14%, although oils are also found on sale, the volatility of which reaches 20%. For synthetic oils, this value usually does not exceed 8%.

In general, it can be said that the lower the Noack volatility value, the lower the oil burnout. Even a small difference - 2,5 ... 3,5 units - can affect oil consumption. A more viscous product burns less. This is especially true for mineral oils.

Coking

In simple words, the concept of coking is the ability of an oil to form resins and deposits in its volume, which, as you know, are harmful impurities in a lubricating fluid. Coking capacity directly depends on the degree of its purification. This is also affected by which base oil was originally used to create the finished product, as well as the production technology.

The optimal indicator for oils with a high level of viscosity is the value 0,7%. If the oil has a low viscosity, then the corresponding value may be in the range of 0,1 ... 0,15%.

Sulphated ash

Sulfate ash content of engine oil (sulphate ash) is an indicator of the presence of additives in the oil, which include organic metal compounds. During the operation of the lubricant, all additives and additives are produced - they burn out, forming the very ash (slag and soot) that settles on pistons, valves, rings.

Sulphated ash content of oil limits the ability of the oil to accumulate ash compounds. This value indicates how much inorganic salts (ash) that remain after the combustion (evaporation) of the oil. It can be not only sulfates (they “scare” car owners, cars with aluminum engines that are “afraid” of sulfuric acid). The ash content is measured as a percentage of the total mass of the composition, [% mass].

In general, ash deposits clog diesel particulate filters and gasoline catalysts. However, this is true if there is a significant consumption of ICE oil. It should be noted that the presence of sulfuric acid in the oil is much more critical than the increased sulfate ash content.

In the composition of full-ash oils, the amount of appropriate additives may slightly exceed 1% (up to 1,1%), in medium-ash oils - 0,6 ... 0,9%, in low-ash oils - not more than 0,5%. Respectively, the lower this value, the better.

Low-ash oils, the so-called Low SAPS (are labeled according to ACEA C1, C2, C3 and C4). They are the best option for modern vehicles. Usually used in cars with an exhaust gas aftertreatment system and cars running on natural gas (with LPG). The critical ash content for gasoline engines is 1,5%, for diesel engines it is 1,8%, and for high power diesel engines it is 2%. But it is worth noting that low ash oils are not always low sulfur, since low ash content is achieved by a lower base number.

Full ash additives, they are also Full SAPA (with marking ACEA A1 / B1, A3 / B3, A3 / B4, A5 / B5). Negatively affect DPF filters, as well as existing three-stage catalysts. Such oils are not recommended for use in engines equipped with Euro 4, Euro 5 and Euro 6 environmental systems.

High sulfate ash content is due to the presence of detergent additives containing metals in the composition of engine oil. Such components are necessary to prevent carbon deposits and varnish formation on pistons and to give oils the ability to neutralize acids, characterized quantitatively by the base number.

Alkaline number

This value characterizes how long the oil can neutralize acids harmful to it, which cause corrosive wear of internal combustion engine parts and enhance the formation of various carbon deposits. Potassium hydroxide (KOH) is used to neutralize. Respectively base number is measured in mg KOH per gram of oil, [mg KOH/g]. Physically, this means that the amount of hydroxide is equivalent in effect to the additive package. So, if the documentation indicates that the total base number (TBN - Total Base Number) is, for example, 7,5, then this means that the amount of KOH is 7,5 mg per gram of oil.

The higher the base number, the longer the oil will be able to neutralize the action of acids.formed during the oxidation of oil and the combustion of fuel. That is, it will be possible to use it longer (although other parameters also influence this indicator). Low detergent properties are bad for the oil, because in this case an indelible deposit will form on the parts.

During the operation of the oil in the internal combustion engine, the alkaline number inevitably decreases, and the neutralizing additives are used up. Such a reduction has acceptable limits, beyond which the oil will not be able to protect against corrosion by acidic compounds. As for the optimal value of the base number, it was previously believed that for gasoline ICEs it would be approximately 8 ... 9, and for diesel engines - 11 ... 14. However, modern lubricant formulations typically have lower base numbers, down to 7 and even 6,1 mg KOH/g. Please note that in modern ICEs do not use oils with a base number of 14 or higher.

The low base number in modern oils is made artificially to suit the current environmental requirements (EURO-4 and EURO-5). So, when these oils are burned in the internal combustion engine, a small amount of sulfur is formed, which has a positive effect on the quality of exhaust gases. However, oil with a low base number often does not protect engine parts from wear well enough.

This means that the optimal SC does not always have to be the maximum or minimum number.

Density

Density refers to the density and viscosity of the engine oil. Determined at an ambient temperature of +20°C. It is measured in kg/m³ (rarely in g/cm³). It shows the ratio of the total mass of the product to its volume and directly depends on the viscosity of the oil and the compressibility factor. It is determined by the base oil and base additives, and also strongly affects the dynamic viscosity.

If the oil evaporation is high, the density will increase. Conversely, if the oil has a low density, and at the same time a high flash point (that is, a low volatility value), then it can be judged that the oil is made on high-quality synthetic base oil.

The higher the density, the worse the oil passes through all channels and gaps in the internal combustion engine, and because of this, the rotation of the crankshaft becomes more difficult. This leads to increased wear, deposits, carbon deposits and increased fuel consumption. But the low density of the lubricant is also bad - because of it, a thin and unstable protective film is formed, its rapid burnout. If the internal combustion engine often runs at idle or in start-stop mode, then it is better to use a less dense lubricating fluid. And with prolonged movement at high speeds - more dense.

Therefore, all oil producers adhere to the density range of oils produced by them in the range of 0,830 .... 0,88 kg / m³, where only the extreme ranges are considered the highest quality. But the density from 0,83 to 0,845 kg / m³ is a sign of esters and PAOs in oil. And if the density is 0,855 ... 0,88 kg / m³, this means that too many additives have been added.

Flash point

This is the lowest temperature at which vapors of heated engine oil, under certain conditions, form a mixture with air, which explodes when a flame is brought up (first flash). At the flash point, the oil also does not ignite. The flash point is determined by heating engine oil in an open or closed cup.

This is an indicator of the presence of low-boiling fractions in the oil, which determines the ability of the composition to form carbon deposits and burn out in contact with hot engine parts. A quality and good oil should have a flash point as high as possible. Modern engine oils have a flash point exceeding +200°C, usually +210…230°C and higher.

congelation point

The temperature value in Celsius, when the oil loses its physical properties, characteristic of a liquid, that is, it freezes, becomes immobile. An important parameter for motorists living in the northern latitudes, and for other car owners who often start the internal combustion engine “cold”.

Although In reality, for practical purposes, the value of the pour point is not used. To characterize the operation of oil in frost, there is another concept - minimum pumping temperature, that is, the minimum temperature at which the oil pump is able to pump oil into the system. And it will be slightly higher than the pour point. Therefore, in the documentation it is worth paying attention to the minimum pumping temperature.

As for the pour point, it should be 5 ... 10 degrees lower than the lowest temperatures at which the internal combustion engine operates. It can be -50°C ... -40°C and so on, depending on the specific viscosity of the oil.

Additives

In addition to these basic characteristics of motor oils, you can also find additional results of laboratory tests for the amount of zinc, phosphorus, boron, calcium, magnesium, molybdenum and other chemical elements. All these additives improve the performance of oils. They protect against scoring and wear of the internal combustion engine, and also prolong the operation of the oil itself, preventing it from oxidizing or better holding intermolecular bonds.

Sulfur - has extreme pressure properties. Phosphorus, chlorine, zinc and sulfur - anti-wear properties (strengthen the oil film). Boron, molybdenum - reduce friction (additional modifier for the maximum effect of reducing wear, scoring and friction).

But besides the improvements, they also have the opposite properties. namely, they settle in the form of soot in the internal combustion engine or enter the catalyst, where they accumulate. For example, for diesel engines with DPF, SCR and storage converters, sulfur is the enemy, and for oxidation converters, the enemy is phosphorus. But detergent additives (detergents) Ca and Mg form ash during combustion.

The protective properties of additives depend on the methods of manufacture and the quality of raw materials, so their quantity is not always an indicator of the best protection and quality. Therefore, each automaker has its own limitations for use in a particular motor.

Life time

In most cars, the oil changes depending on the mileage of the car. However, on some brands of lubricating fluids on canisters, their expiration date is directly indicated. This is due to the chemical reactions that occur in the oil during its operation. It is usually expressed as the number of months of continuous operation (12, 24 and Long Life) or the number of kilometers.

Engine oil parameter tables

For completeness of information, we present several tables that provide information on the dependence of some engine oil parameters on others or on external factors. Let's start with a group of base oils in accordance with the API standard (API - American Petroleum Institute). So, oils are divided according to three indicators - viscosity index, sulfur content and mass fraction of naphthenoparaffin hydrocarbons.

| API classification | I | II | III | IV | V |

|---|---|---|---|---|---|

| Content of saturated hydrocarbons, % | <90 | > 90 | > 90 | PAO | Ethers |

| Sulfur content, % | > 0,03 | <0,03 | <0,03 | ||

| Viscosity index | 80 ... 120 | 80 ... 120 | > 120 |

Currently, a large number of oil additives are on the market, which in a certain way change its characteristics. For example, additives that reduce the amount of exhaust gases and increase viscosity, anti-friction additives that clean or extend service life. To understand their diversity, it is worth collecting information about them in a table.

| Property group | Additive types | appointment |

|---|---|---|

| Part surface protection | Detergents (detergents) | Protects the surfaces of parts from the formation of deposits on them |

| Dispersants | Prevent the deposition of wear products of the internal combustion engine and oil degradation (minimizes the formation of sludge) | |

| Anti-wear and extreme pressure | Reduce friction and wear, prevent seizing and scuffing | |

| Anti-corrosion | Prevent corrosion of engine parts | |

| Transform oil properties | Depressor | Reduce the freezing point. |

| Viscosity modifiers | Expand the temperature range of application, increase the viscosity index | |

| Oil protection | Anti-foam | Prevent foam formation |

| Antioxidants | Prevent oil oxidation |

Changing some of the engine oil parameters listed in the previous section directly affects the operation and condition of the car's internal combustion engine. This can be displayed in a table.

| Index | Trend | Cause | Critical parameter | What affects |

|---|---|---|---|---|

| Viscosity | Increases | Oxidation products | 1,5 times increase | Starting Properties |

| congelation point | Increases | Water and oxidation products | No | Starting Properties |

| Alkaline number | Decreases | Detergent action | Decrease by 2 times | Corrosion and reduced life of parts |

| ash content | Increases | Alkaline additives | No | The appearance of deposits, wear of parts |

| Mechanical impurities | Increases | Equipment wear products | No | The appearance of deposits, wear of parts |

Oil selection rules

As mentioned above, the choice of one or another engine oil should be based not only on viscosity readings and tolerances of car manufacturers. In addition, there are also three mandatory parameters that must be taken into account:

- lubricant properties;

- oil operating conditions (ICE operating mode);

- structural features of the internal combustion engine.

The first point largely depends on what type of oil is synthetic, semi-synthetic or completely mineral. It is desirable that the lubricating fluid has the following performance characteristics:

- High detergent dispersing-stabilizing and solubilizing properties in relation to insoluble elements in the oil. The mentioned characteristics allow you to quickly and easily clean the surface of the working parts of the internal combustion engine from various contaminants. In addition, thanks to them, it is easier to clean the parts from dirt during their dismantling.

- The ability to neutralize the effects of acids, thereby preventing excessive wear of internal combustion engine parts and increasing its overall resource.

- High thermal and thermal-oxidative properties. They are needed in order to effectively cool the piston rings and pistons.

- Low volatility, as well as low oil consumption for waste.

- The absence of the ability to form foam in any state, even in cold, even in hot.

- Full compatibility with the materials from which the seals are made (usually oil-resistant rubber) used in the gas neutralization system, as well as in other internal combustion engine systems.

- High-quality lubrication of internal combustion engine parts in any, even critical, conditions (during frost or overheating).

- The ability to pump through the elements of the lubrication system without problems. This not only provides reliable protection of the internal combustion engine elements, but also facilitates starting the internal combustion engine in cold weather.

- Not entering into chemical reactions with metal and rubber elements of the internal combustion engine during its long downtime without work.

The listed indicators of the quality of engine oil are often critical, and if their values are below the norm, then this is fraught with insufficient lubrication of individual parts of the internal combustion engine, their excessive wear, overheating, and this usually leads to a decrease in the resource of both individual parts and the internal combustion engine as a whole .

any motorist should periodically monitor the level of engine oil in the crankcase, as well as its condition, since the normal operation of the internal combustion engine directly depends on this. As for the choice, it should be carried out, relying, first of all, on the recommendations of the engine manufacturer. Well, the above information about the physical properties and parameters of oils will surely help you make the right choice.