Variable valve timing. What are the benefits? What breaks?

Constant valve timing over the entire engine speed range is a cheap but inefficient solution. Phase change has many advantages.

Constant valve timing over the entire engine speed range is a cheap but inefficient solution. Phase change has many advantages.

In search of opportunities to improve piston, four-stroke internal combustion engines, designers are consistently introducing new solutions to improve dynamics, extend the useful speed range, reduce fuel consumption and reduce exhaust emissions. In the fight to optimize fuel combustion processes, engineers once used variable valve timing to develop more efficient and environmentally friendly engines. Timing controls, which greatly improved the process of filling and cleaning the space above the pistons, proved to be excellent allies of designers and opened up completely new possibilities for them.

In classic solutions without changing the valve timing, the valves of a four-stroke engine open and close according to a certain cycle. This cycle is repeated in the same way as long as the engine is running. In the entire speed range, neither the position of the camshaft (s), nor the position, shape and number of cams on the camshaft, nor the position and shape of the rocker arms (if installed) change. As a result, ideal opening times and valve travel only appear over a very narrow rpm range. In addition, they do not correspond to the optimal values and the engine runs less efficiently. Thus, factory-set valve timing is a far-reaching compromise when the engine is working properly but cannot show its true capabilities in terms of dynamics, flexibility, fuel consumption and exhaust emissions.

In classic solutions without changing the valve timing, the valves of a four-stroke engine open and close according to a certain cycle. This cycle is repeated in the same way as long as the engine is running. In the entire speed range, neither the position of the camshaft (s), nor the position, shape and number of cams on the camshaft, nor the position and shape of the rocker arms (if installed) change. As a result, ideal opening times and valve travel only appear over a very narrow rpm range. In addition, they do not correspond to the optimal values and the engine runs less efficiently. Thus, factory-set valve timing is a far-reaching compromise when the engine is working properly but cannot show its true capabilities in terms of dynamics, flexibility, fuel consumption and exhaust emissions.

If elements are introduced into this fixed, compromise system that allow changing the time parameters, then the situation will change dramatically. Reducing the valve timing and valve lift in the low and medium speed range, lengthening the valve timing and increasing valve lift in the high speed range, as well as repeated "shortening" of the valve timing at speeds close to maximum, can significantly expand the speed range at which the valve timing parameters are optimal. In practice, this means more torque at lower revs (better engine flexibility, easier acceleration without downshifting), as well as achieving maximum torque over a wide rev range. Therefore, in the past, in the technical specifications, the maximum torque was linked to specific engine speeds, and now it is most often found in a certain speed range.

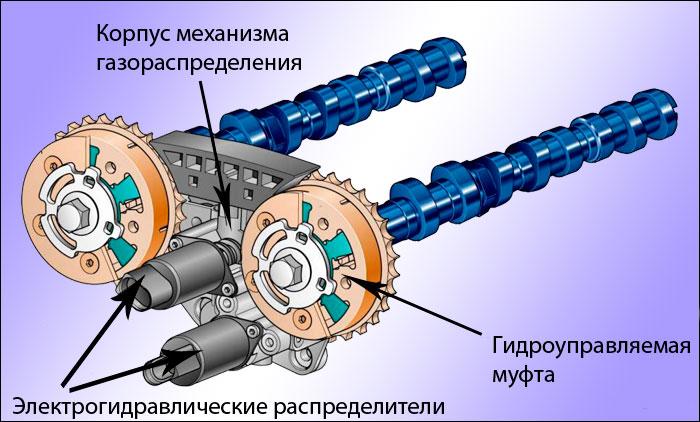

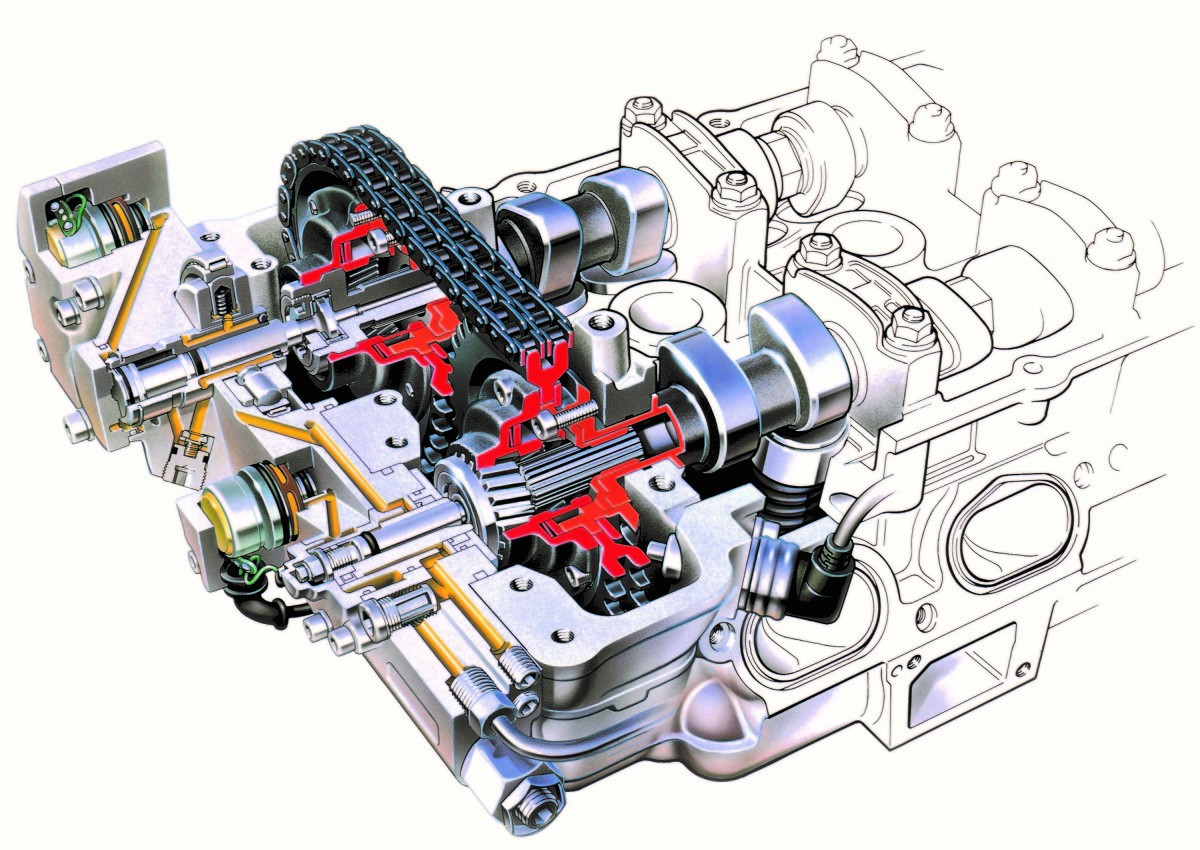

Timing adjustment is carried out in various ways. The advance of the system is determined by the design of the variator, i.e. executive element responsible for changing parameters. In the most complex solutions, it is the entire system that is controlled by a computer, taking into account many different factors. It all depends on whether you need to change only the opening time of the valves or their stroke. It is also important whether the changes are abrupt or gradual.

Timing adjustment is carried out in various ways. The advance of the system is determined by the design of the variator, i.e. executive element responsible for changing parameters. In the most complex solutions, it is the entire system that is controlled by a computer, taking into account many different factors. It all depends on whether you need to change only the opening time of the valves or their stroke. It is also important whether the changes are abrupt or gradual.

In the simplest system (VVT), the variator, i.e. the element that performs the angular displacement of the camshaft is mounted on the camshaft drive pulley. Under the influence of oil pressure and thanks to specially designed chambers inside the wheel, the mechanism can rotate the hub with the camshaft installed in it relative to the wheel housing, which is acted upon by the timing drive element (chain or toothed belt). Due to its simplicity, such a system is very cheap, but ineffective. They were used by, among others, Fiat, PSA, Ford, Renault and Toyota in some models. Honda's (VTEC) system delivers much better results. Up to a certain rpm, the valves are opened by cams with profiles that promote smooth and economical driving. When a certain speed limit is exceeded, the set of cams shifts and the levers press against the cams, which contributes to a dynamic sports driving. Switching is carried out by a hydraulic system, the signal is given by an electronic controller. The hydraulics are also responsible for ensuring that only two valves per cylinder operate in the first phase, and all four valves in the second phase. In this case, not only the opening times of the valves change, but also their stroke. A similar solution from Honda, but with a smooth change in the valve timing is called i-VTEC. Honda-inspired solutions can be found in Mitsubishi (MIVEC) and Nissan (VVL).

Good to know: fake offers. There are scammers online! Source: TVN Turbo / x-news