Variable turbine geometry - is it better than fixed geometry?

Content

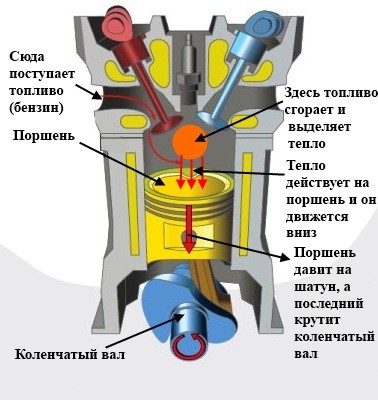

The first types of turbochargers were controlled by pressure applied to the wastegate. When the boost pressure limit was reached, the valve opened, allowing excess exhaust gases to escape into the exhaust. Variable turbine geometry works differently and additionally includes the so-called. rudders, i.e. oars. What is it all about? we answer!

What is a variable geometry turbine?

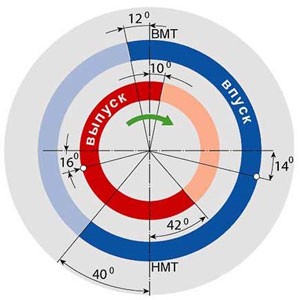

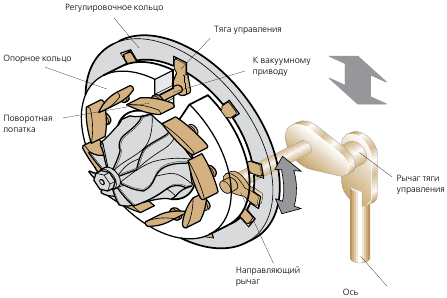

As mentioned above, the turbine geometry in VHT compressors (or VGT or VTG depending on the manufacturer) can be fixed or variable. The idea is to manage the exhaust gases produced by the engine as efficiently as possible. The VNT turbine has an additional ring on the hot side. Oars (or rudders) are placed on it. The angle of their deviation is regulated by a vacuum valve. These blades can reduce or increase the space for the flow of flue gases, which affects the speed of their flow. This allows the hot side impeller to spin faster even at idle.

How does a fixed and variable geometry turbocharger work?

When the engine is idling or in the low rpm range (depending on engine assembly and turbine size), there is enough exhaust gas to keep the turbine from generating boost pressure. Turbo lag occurs when the gas pedal is pressed hard on fixed geometry turbo units. This is a moment of hesitation and no sudden acceleration. Such a turbine is not able to accelerate immediately.

Variable geometry turbine operation

The variable geometry of the turbine means that even at low rpm, when the engine produces little exhaust gas, a usable boost pressure can be achieved. The vacuum valve moves the steering wheel to a position to reduce exhaust flow and increase exhaust velocity. This results in faster rotation of the rotor and rotation of the compression wheel on the cold side. Then even an immediate press on the accelerator without hesitation will translate into a clear acceleration.

Design of variable geometry turbocharger and conventional turbocharger

A driver looking at a turbine from the outside may not notice the difference between one type and another. The variable geometry is hidden on the hot side and will not be visible to the eye. However, if you look closely, you can see a much larger portion of the turbine right next to the exhaust manifold. Additional controls should fit inside. In some types of VNT turbines, there are also electro-pneumatic control valves with an additional stepper motor, which is also visible when inspecting the equipment.

Turbine - variable geometry and its advantages

One of the advantages of this system you already know is that it eliminates the effect of turbo lag. There are several ways to eliminate this phenomenon, such as enriching the mixture or using hybrid turbochargers. However, variable turbine geometry works very well in cars with small engines where the torque curve needs to be high as early as possible. In addition, in order for the core with the rotor and compression wheel to accelerate, the engine does not need to be turned to high speeds. This is important for the life of the unit, which can generate maximum torque at lower RPMs.

Turbocharger with variable geometry - disadvantages

The disadvantages of a variable geometry turbine are:

- great complexity of the design of the device itself. This results in the cost of purchasing and regenerating such a turbine;

- the vane control system is susceptible to contamination.

Improper use of the vehicle (and basically the engine itself) can significantly shorten the life of the turbocharger. Any leaks in the cooling system and pressure also have a significant effect on the operation of the component. Fortunately, variable geometry is regenerated and often does not need to be replaced.

It's hard not to notice that the variable geometry of the turbine is useful, which you will especially appreciate when driving around the city and overtaking. VNT allows you to reduce the effect of turbo lag to almost zero. However, in the event of a failure, it is extremely difficult to restore the original parameters of the regenerated elements. Although they do not always need to be replaced with new ones, they are more difficult to repair than traditional components. A change in performance can then be observed, for example when braking. You must decide if variable geometry is better for your vehicle than fixed geometry.