How are chisels made?

Content

| Carbon steel is turned into chisels through a process called "heat treating". It can also be "forged" for increased strength. These general principles apply to both cold and construction bits. Any differences in procedure will depend on the type of bit being produced and the manufacturer. | |

Heat treatment | |

| To turn into tools that will work properly, carbon steel is heat treated. For cold bits, this ensures that the tool will cut metals. |

| First, the steel is hardened, which allows the tool to better withstand weathering. |

| However, this process makes the steel incredibly brittle, so it is subsequently "annealed" and "tempered" to reduce this. The hardening process is achieved by heating the steel and then cooling it down. This is done using a technique called "quenching". |

| You can achieve enough heat using a few items, including a forge or a blowtorch. |

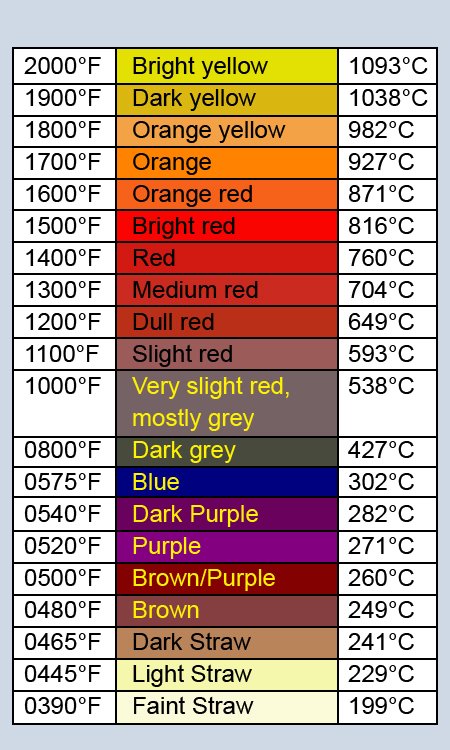

| When the steel is heated, it changes color depending on the current temperature. Using the glow chart, the user can determine exactly what temperature the steel is currently at. |

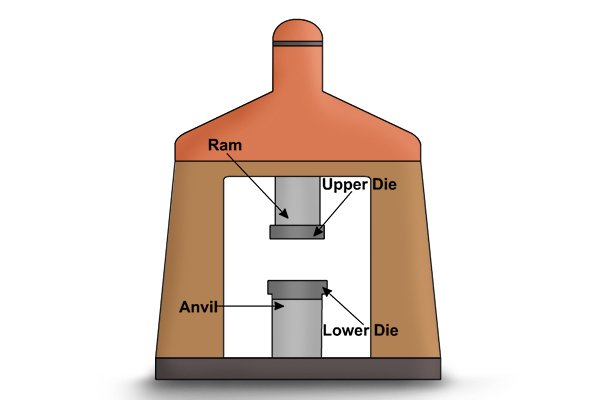

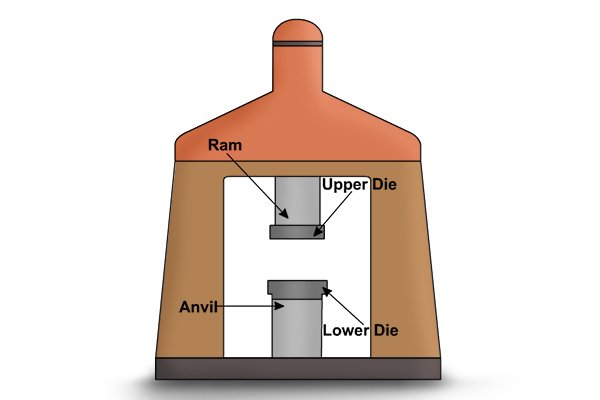

Forging | |

| When purchasing chisels, you may find that they are advertised as "forged". These words indicate how the product was made, as well as how durable it will be. |

| Like normal forging, red-hot metal is repeatedly struck with a hammer to shape it. |

| However, unlike conventional forging, the metal is hammered into a die (like a mold) that contains the shape of the future design. There are two types of stamping: open and closed. |

| Forging is also an indication of quality, as a forged tool is usually stronger than a machined or cast tool. |