How and with what to independently fit a car torpedo

Content

The front panel of the cabin (torpedo or more aristocratically outdated concept - parpriz) is always in sight, this is the face of the automotive interior. Therefore, covering it with high-quality material is an intention as noble as it is responsible. Yes, and quite difficult to perform, but by trying you can achieve a decent result.

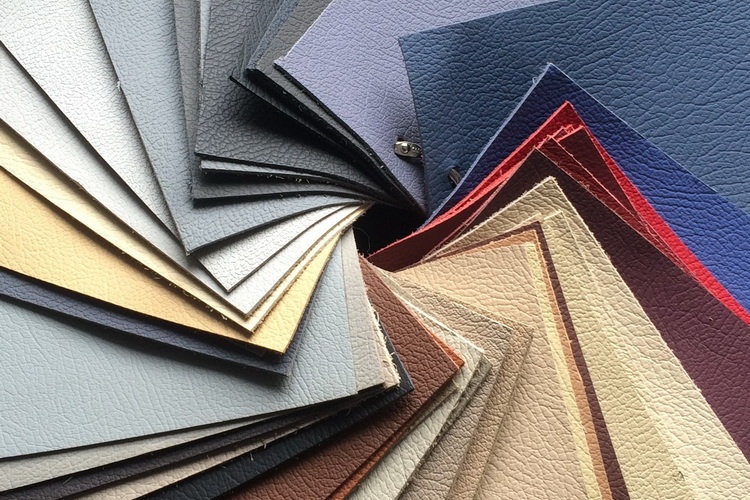

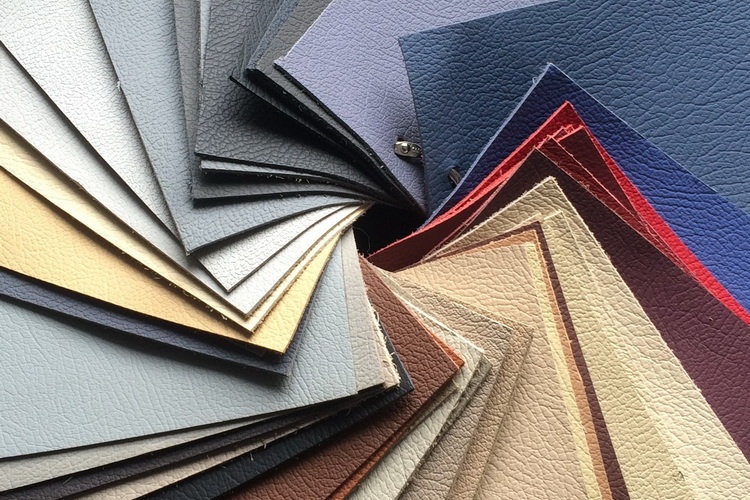

How to choose material

This is a crucial stage of work, moreover, it is complicated by the fact that pictures on the Internet cannot be trusted. The material must be seen, and most importantly, touched directly in the store.

Thinking before that not only about decorative qualities, but also taking into account color shades, tactile sensations, and also remembering practicality, it is undesirable for the material to be difficult to clean and constantly take on all the pollution.

A natural skin

Good, proven stuff. Perfectly isolates all unwanted sounds, has heat-insulating properties, is resistant to dirt and easily amenable to the simplest cleaning methods.

At the same time, high-quality leather is expensive and, if we talk about fashion, it is somewhat outdated, but it is a classic, and it always has its connoisseurs.

Especially worth noting is the durability of the leather cover. From the point of view of mechanical influences, the supply here is large, because even the constantly abraded seats and steering wheel are covered with leather.

For a dashboard, resistance to solar radiation is important, and here the skin is also at its best, and the disadvantage will be the high price of such a coating.

Leatherette

The days of cheap leatherette or leatherette for student briefcases are long gone. Now it is customary to call it eco-leather, and if you do not find fault, then in all its qualities such material is not particularly inferior to a natural product.

It will, however, be much cheaper. It is quite strong and durable, has resistance to influencing factors, although the variation in quality for different samples is very large. We will have to collect more information on the selected material.

Autocarpet

The advantages of autocarpet will be low price, heat-insulating properties and excellent ability to absorb noise.

Decorative abilities and durability can be considered satisfactory, as well as the appearance, which can be denoted by the word "an amateur".

But it is easier to work with this material and it can be recommended for novice owners of inexpensive cars who have lost their parprise appearance due to age or the deployment of airbags.

Vinyl film

A characteristic feature of vinyl is the richness of the choice of color shades and textures. Sometimes it is simply impossible to realize the whimsical fantasy of an amateur designer in another way.

The same skin will not be able to realize an imitation of neoclassicism - carbon, or even a mirror chrome or metallic. Which is as effective as it is dangerous. Yet the panel is always in the driver's field of vision.

The low price of vinyl trim allows you to experiment, mastering the difficult art of interior upholstery, and the lack of strength and durability of the coating will be compensated by the possibility of its quick replacement as the decorative effect is lost. And vinyl film does not require any special care.

Alcantara

An excellent coating that perfectly imitates suede, while being ordinary synthetics. Creates a calm, almost homely atmosphere in the cabin, especially pleasant to the touch.

Automotive Alcantara is well suited for covering complex surfaces, stable over time and durable. Very often used in factory interior trim.

How to fit a dashboard in a car yourself

Do not expect that all work can be done without disassembling the cabin. The entire front panel will have to be removed to provide full access.

Tools

You will need both a standard locksmith tool for assembly and disassembly work to remove the torpedo, and a more specialized one, directly for tightening operations.

- A set of screwdrivers and wrenches, providing work in hard-to-reach places. Mirrors, flexible holders and gimbals may be required.

- Special device for dismantling plastic clips and latches.

- Industrial hair dryer with air temperature control.

- You may need a sewing machine to work with leather.

- Marker, knives and scissors. The cutting tool must be of high quality and sharp.

- Spatulas, rollers and brushes.

You should not hope that a cheap and low-quality tool will allow you to get a decent result.

Even in capable hands, they can ruin everything, after which they will have to start over, incurring material losses.

Consumables

The list of consumables is determined by the selected material. But some positions of the list will become common for all coverages:

- liquid and wipes for degreasing the surface, used in painting;

- sandpaper of varying degrees of graininess, very thin is not required here;

- glue for the selected cover material;

- non-woven fabric for creating a layout - patterns, preferably with a spot application of glue;

- threads for sewing leather, here you can not save on quality and decorativeness;

- directly the covering material itself, better with a margin.

You will also need disposable gloves to protect your hands and anti-static wipes to remove dust from the part.

Preparation (dashboard removal)

It is necessary to work in accordance with the repair manual for a particular car, since not all fasteners are visible to the eye.

Plastic elements, especially those that have already served, must be handled with care, they become brittle over time, and if broken attachment points are not repaired, this place can become a source of annoying noise in the future. Moreover, the mass of the torpedo will increase markedly.

Tightening technology + video

Work on the removed parprise begins with the preparation of patterns. The locations of the seams are determined, and a decision is made on the size of the pieces of material. Various options are possible, ranging from a single cover to gluing small fragments.

Non-woven blanks are glued onto the workpieces to be processed and seam tolerances are determined.

Interlining, unlike paper, has increased strength and is used in the clothing industry as a lining material. After complete pasting, the patterns are carefully separated from the parts of the torpedo.

The removed patterns are superimposed on the material lying on a flat surface from the wrong side. The borders, taking into account the seams, are outlined with a marker, and the details are cut out.

For the final check, the sheets of material are once again applied to the dashboard, and all geometry is controlled. After that, the cover can be sewn, if it is provided by the technology of a particular material.

Before pasting the surface of the torpedo must be prepared. Details are sanded, degreased, dust and other contaminants are carefully removed from them. A primer layer is applied, which can be a primer or glue. The same is done with the details of the tight material.

A layer of glue is applied to the dried material, in accordance with its technological features. After that, you can proceed directly to pasting.

Watch this video on YouTube

It is necessary to carefully monitor the exception of air bubbles, so it is better to act from the center to the edges. All seam locations must be aligned and located along the marked lines.

Pasted parprise is blown with an industrial dryer for uniform shrinkage and full distribution of glue over the surface, at this stage it is still possible to even out the formed folds and bubbles. A rubber roller is used to roll out the material. Complete polymerization of the adhesive usually occurs within a day.

Errors

Experience is not gained immediately. Therefore, for the first time, you can get air bubbles, uneven seams, and also show unnoticed defects in the original surface.

There may also be errors in the choice of material. You should especially remember about the persistent smell in the cabin if substances are used that are not intended for this.

Cheap glue of wide application can weather for years, so it is better to purchase all consumables from a specialized supplier in the form of a single complex.

The importance of accurate assembly and disassembly operations has already been mentioned. At the installation stage, you may encounter a changed panel geometry, you need to think about this when marking the patterns.