How To: Use fiberglass filler to repair car body

Content

Ensuring Proper Repair When Welding Automotive Sheet Metal

Any welding performed on a vehicle requires specific steps to ensure proper repair. For example, a through primer must be applied to the surface to be welded; it is necessary to apply anti-corrosion protection to the reverse side of the welding site, etc. In this article we will talk about why fiberglass is needed for body repairs.

What is fiberglass?

Raw fiberglass is a soft fabric like material. When saturated with liquid resin and hardening, it becomes hard and very durable. There aren't many fiberglass parts in today's cars as they all started using other composites like SMC and carbon fiber. However, fiberglass was used on early model corvettes, truck hoods, and many other parts. There are also aftermarket parts that are made from fiberglass and are still used today for boats and jet skis.

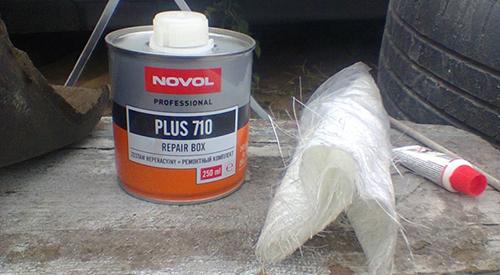

The difference between fiberglass and fiberglass filler

Fiberglass filler is supplied in cans and mixed with cream hardener. It blends just like regular body filler, but it's thicker and a little harder to blend. The filler is actually fiberglass. They are short hair and long hair. This is the length of the fiberglass that interferes with the filler. Both provide excellent waterproof properties as they do not absorb water. Both fiberglass fillers are stronger than conventional body filler. Long hair filler provides the most strength of the two. However, these fillers are very difficult to grind. The padding is also thick, making it difficult to level and smooth out like regular body padding.

Why use fiberglass filler if it's so hard to sand?

The reason we use fiberglass filler in car body repairs is not for added strength, but for water resistance. It is recommended that a thin layer of fiberglass putty be applied over any welding being performed. The filler of the body absorbs moisture, which leads to corrosion and rust. By using fiberglass, we eliminate the problem of moisture absorption. Since our primary goal is to seal the weld area, short-haired fiberglass is sufficient for the application.

What can fiberglass filler be applied to?

This filler can be used over bare metal or fiberglass. In a car body, this is usually the first layer applied over the weld.

Completion of the repair

Like I said before, fiberglass doesn't sand well. This is why I recommend applying a small amount to the welded areas and sanding roughly. You can then apply the body filler over the fiberglass filler and complete the repair as usual using the body filler.

Tips

- Sand or file the fiberglass filler before it is fully cured. This will allow you to shape the infill in a green state, which saves a lot of time and sanding. However, you only have a small window of time. Typically 7 to 15 minutes after application depending on temperature and amount of hardener used.

Warnings

- You should always wear proper protective gear when sanding any filler. However, extreme care must be taken when sanding fiberglass products. Not only does it itch and irritate the skin, but breathing fiberglass is extremely unhealthy. Be sure to wear an approved dust mask, gloves, goggles, and you may even want to wear a disposable painting suit. If a piece of fiberglass comes into contact with your skin, take a cold shower. This will help shrink the pores and allow the fiberglass to be washed away.