How to zero a micrometer?

Zeroing Your Micrometer

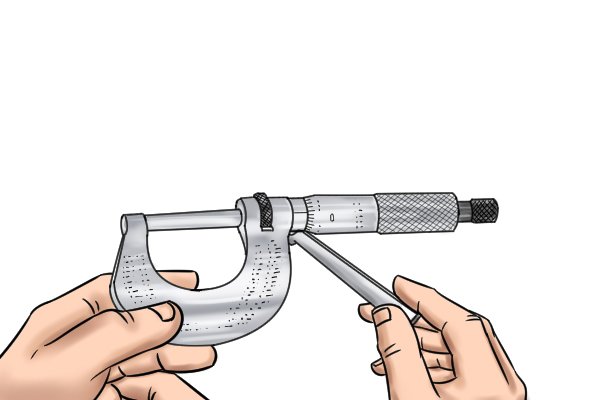

Before using a micrometer, it is important to ensure that it is properly zeroed to ensure accurate and reliable measurements.This means that when the measuring surfaces of the heel and spindle of the micrometer are closed together, the scales will read zero.

The micrometer sleeve is adjustable to align the index bar with the zero (0) on the thimble.Before checking the zero position, make sure that the measuring surfaces are clean and free from defects.

To zero the micrometer, the same procedure is used as for measurement.

To check the zero position, rotate the thimble with a micrometric ratchet until the spindle approaches the anvil.

To check the zero position, rotate the thimble with a micrometric ratchet until the spindle approaches the anvil.Gently turn the ratchet as you approach the anvil and keep turning until the spindle stops turning. The ratchet will continue to rotate, applying the necessary force to accurately measure the zero position.

Using just the thimble of a micrometer requires some skill and practice to achieve the right "feel".Then check that the zero (0) on the thimble matches the mark on the sleeve.

Check several times by releasing the spindle several times and then rechecking zero. If the zero repeats, your micrometer is ready for use. If the zero does not match the index line, the micrometer will need to be re-zeroed using the adjustment key normally supplied with the instrument. When the two measuring surfaces are in the correct zero position, use the locking device to lock the spindle. so that nothing moves.

Check several times by releasing the spindle several times and then rechecking zero. If the zero repeats, your micrometer is ready for use. If the zero does not match the index line, the micrometer will need to be re-zeroed using the adjustment key normally supplied with the instrument. When the two measuring surfaces are in the correct zero position, use the locking device to lock the spindle. so that nothing moves.

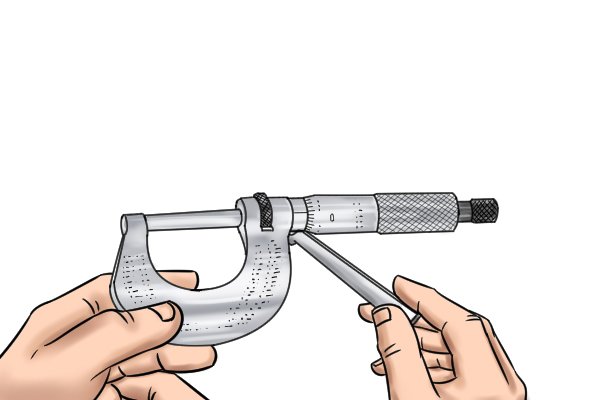

Insert the hook of the included wrench into the hole in the base of the bushing. Carefully turn the sleeve until the index line is at zero.

Insert the hook of the included wrench into the hole in the base of the bushing. Carefully turn the sleeve until the index line is at zero.Unlock the spindle, then repeat the zeroing procedure until the zero is at the index line.