How to determine the wear of silent blocks: causes and consequences

Content

There are different ways to provide mobility in the joints of the levers and suspension rods of the car. The necessary travel of the guide apparatus is created by using hinges, which can be on various kinds of bearings, ball joints or rubber-metal compound bushings. The latter, for their silent nature of work and elasticity, are usually called silent blocks.

Why silent blocks are torn

The classic silent block consists of the following parts:

- outer clip in the form of a metal sleeve;

- rubber working part, it can also be made of other elastic material, for example, polyurethane;

- inner sleeve with a hole for the axle.

The rubber is vulcanized or bonded to the metal of both bushings. This is done so that all relative displacements of the arm and axle occur within the elastic material. If the rubber is torn off from the metal, then the silent block will turn into an ordinary plain bearing of poor quality.

Friction on the clips will quickly lead to wear, it is not structurally provided for, and there is no lubrication. The hinge will creak, significant backlash will quickly appear in it, the assembly will fail.

Sometimes there is no vulcanization or gluing in silent blocks; a simple rubber bushing is used, tightly sandwiched between the clips. In this case, the absence of rotation and friction of materials is ensured by the tightness and elasticity of the parts.

Such a hinge can be disassembled, only the elastic part changes. This is convenient for maintainability, and also reduces the price of the product.

With any design, rubber is not eternal. There can be several reasons for the break:

- destruction of the vulcanization of the elastic part to the metal of the clips;

- weakening of the fit of the elastic sleeve, cranking and subsequent intense wear;

- natural fatigue of the material under the influence of multiple deformations;

- atmospheric action of aggressive substances, which causes the degradation of rubber properties;

- single extreme loads of axial, radial or angular direction, when the maximum angles of operation of the unit are violated, the material leaves the zone of elastic deformation and breaks;

- errors during installation, when the initial installation of the node is incorrectly selected.

The elastic element that has lost its characteristics must be replaced as an assembly with clips. If the repair technology provides for the replacement of only the bushings, then the cages and shafts are subject to inspection, since they also wear out.

With a strong change in geometry, the new bushing will not be clamped and will immediately rotate with a rapid subsequent destruction.

How to know it's time to change the silent block

There are several diagnostic methods.

- The easiest - visual control. They usually start with it at the service station, and they end up with it, since the task is to change more and bring the car as close as possible to ideal condition. You can reject all available silent blocks, including those that are still alive. It is enough to find cracks on the protruding surfaces of the rubber. Not entirely accurate, but if the rubber has already begun to crack, then it will not last long.

- The presence of a creak when rocking the machine, sometimes disappearing when spraying the hinge with a penetrating lubricant such as the well-known WD40. This usually means a break in vulcanization and is generally justified.

- Backlash in the hinge. It should not be there, it appears with heavy wear.

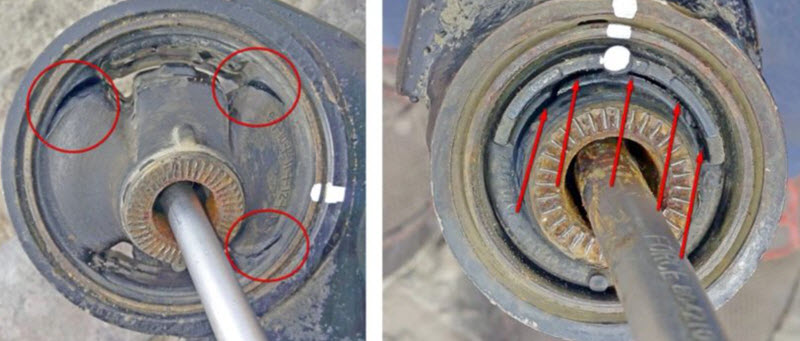

- Displacement of the axes of the outer cage regarding the internal. This is what happens with wear, evenly the hinges do not wear out, just as the rubber does not push through.

- Full disappearance of rubber, an abundance of rust, knocks. The most neglected case requiring immediate replacement.

With the wear of silent blocks, even the very initial one, the behavior of the car changes dramatically, the suspension works sluggishly, and the handling deteriorates. This is also a symptom.

What happens if the rubber-metal hinges are not changed on time

Everything in the suspension is connected. If you ignore the wear of the hinges, then the conjugated nodes, the axles of the levers, the lugs, the shock absorbers and the fenders will begin to collapse. Wheel alignment angles change, tire consumption exceeds all standards. The creaks and knocks intensify.

Few people want to go further with such a suspension, and the cost of repairs increases with every kilometer. Security worsens, you can fly off the road in a fairly familiar situation.

How to check the silent blocks of the front levers and the rear beam yourself

It is necessary to look closely at the methods of diagnostics of service station specialists. Main methods of control:

- rocking the car on the suspension with monitoring the work of the hinges;

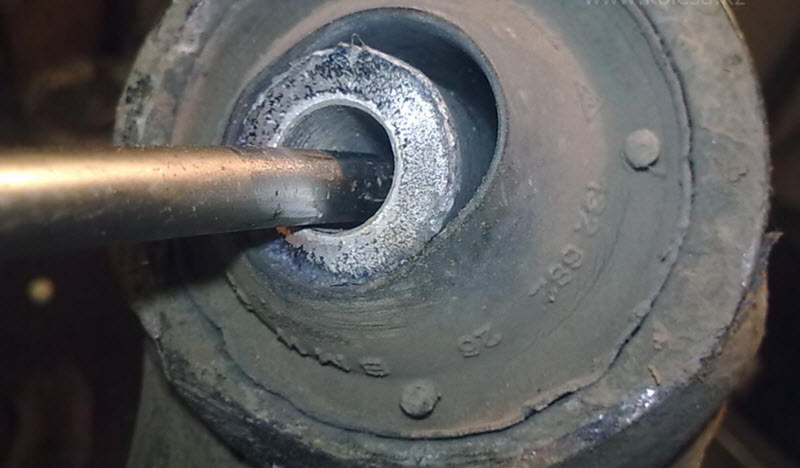

- loading levers in the area of silent blocks with a lever, for example, a mount;

- identifying sources of creaking with grease or even just water;

- observation of the displacement of the axes of the clips, in the new silent block all the circles there have a common center even under load;

- the rear beam is more difficult to check, but the principle is the same, if there is a relative displacement of the clips during rocking, the hinges need to be replaced.

The sooner you start repairing, the less problems will arise during dismantling. A defective joint heats up and corrodes strongly, after which it is difficult to press it out.

Not everyone has a press, as well as mandrels of the required diameter, so it’s better to immediately contact the chassis master. He will also tell you a trusted manufacturer of parts, cheap crafts sometimes serve worse than already worn ones.