How to determine which clutch cylinder is not working GCC or RCC

Content

On some machines, there is still a mechanical clutch drive. Usually this is a cable in a sheath that is flexible for laying in place, but rigid in the longitudinal direction. The design is simple, but not distinguished by smooth operation and reliability. A hydraulic drive serves much better when the force is transmitted through an incompressible fluid, the same one that is massively used in brake systems.

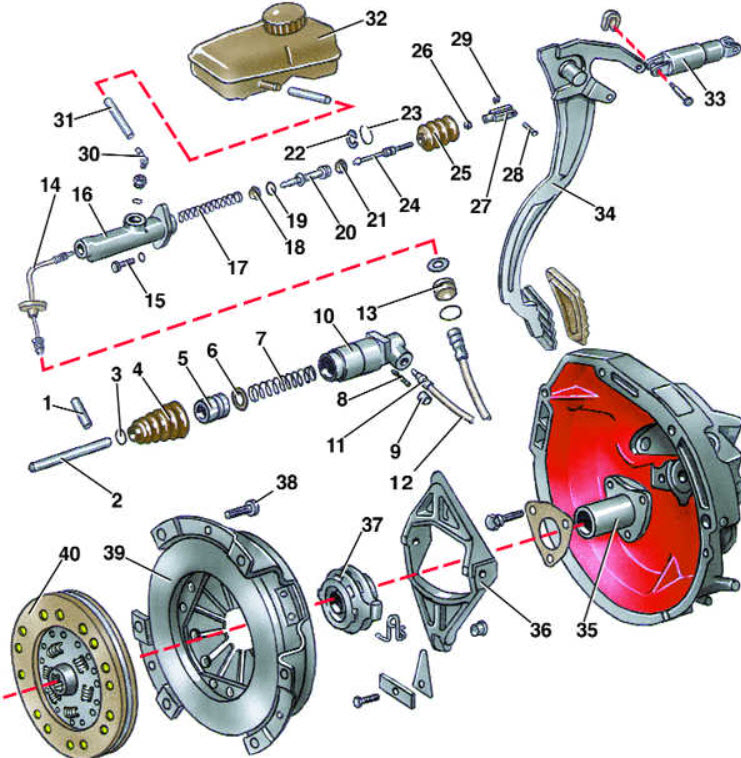

Clutch hydraulic drive device

To carry out a qualitative diagnosis of a failed clutch release drive, the best option would not be to collect and tabulate the signs of a malfunction of a particular node, as is done in the mass literature for beginners, but to understand the principle of the system as a whole and the arrangement of its two main components - the main and working cylinders (GCC and RCS).

Then all the signs will automatically point to the source of the problem and unambiguously lead to further corrective actions.

The drive includes:

- GCS and RCS;

- storage tank with liquid;

- connecting pipeline with rigid tubes and flexible reinforced hose;

- pedal rods and release forks at different ends of the drive.

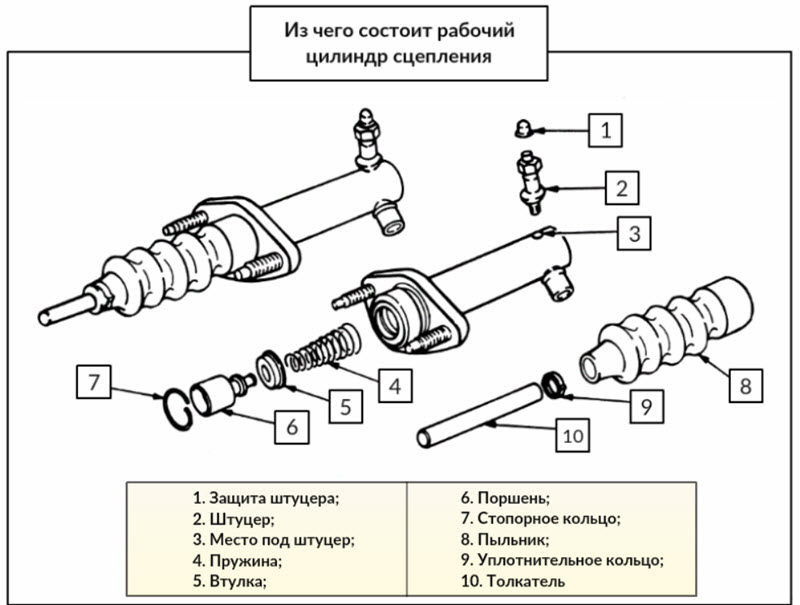

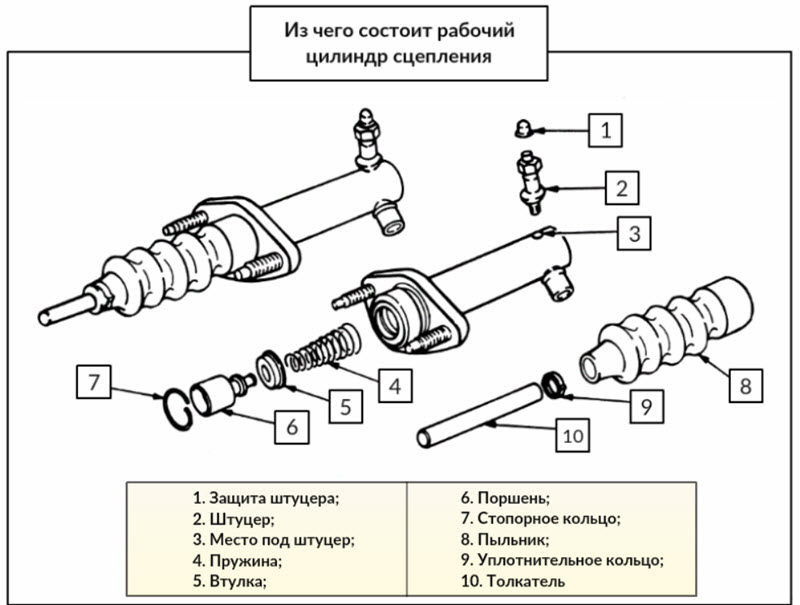

The device of the cylinders is approximately similar, the difference is fundamentally mirror, in one case the piston presses on the liquid, in the other it experiences pressure itself, transferring it to the actuating rod.

The rest of the composition is the same:

- case with cylinder mirror;

- piston;

- sealing self-compressing annular cuffs;

- piston return springs;

- fluid inlet and outlet fittings;

- bypass and pumping holes;

- outer anthers and additional seals.

When you press the pedal, the rod connected to it presses on the piston of the master cylinder. The space behind the piston is filled with an incompressible hydraulic agent, it is a special liquid with lubricating properties, which has a certain viscosity that is stable over the temperature range.

At the very beginning of the movement of the piston, its edge, sealed with a cuff, covers the bypass hole in the cylinder wall, the cavity behind the piston and the space of the storage tank are separated.

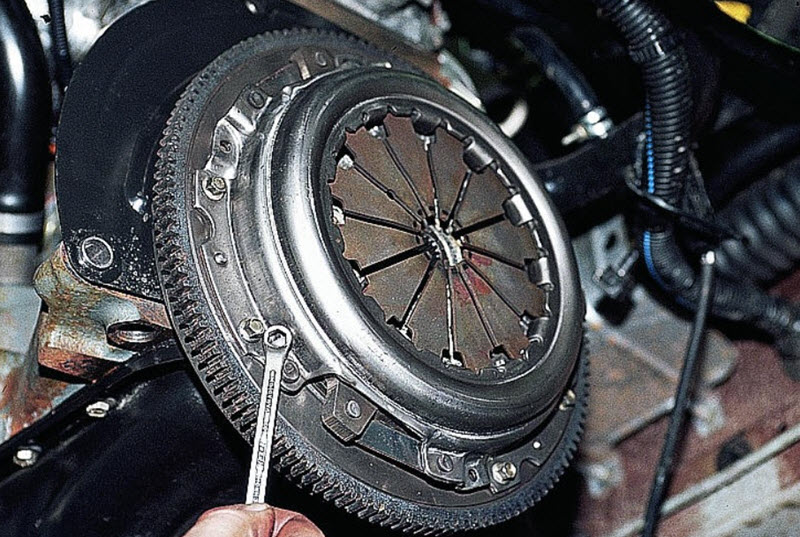

The pressure in the line increases, which causes the movement of the RCS piston, which compresses the powerful spring of the pressure plate of the clutch assembly. The driven disk gains freedom, the transmission of torque from the engine flywheel to the input shaft of the gearbox stops.

Watch this video on YouTube

When the pedal is released, under the action of the springs of the pressure plate and the return in the main cylinder, the RCS and GCS pistons return to their original position. The cavities of the line and the tank again communicate through the opened bypass hole.

How to understand which of the clutch cylinders is not working

In the event of a failure or malfunction in the shutdown drive, it is important to find out where the failure occurred. If we are talking about hydraulics, then GCC and RCC can be the cause.

Typical malfunctions of the GCC (clutch master cylinder)

Almost always, the problem occurs due to a violation of the tightness of the piston seal. This assembly experiences friction in the brake fluid (TF) medium.

There is lubrication and a certain protection against corrosion. But the possibilities are limited, especially as materials age and TF degrade. Commercial products are subject to the main problem to varying degrees - the accumulation of moisture from the air due to hygroscopicity.

There are boundary conditions for mechanical wear and corrosion of metal parts. In addition, in some samples, metals suffer from electrochemical processes. For example, the combination of a cast-iron body and an aluminum piston creates a galvanic couple, where the aged TJ serves as an electrolyte. There is an additional erosion of metals and contamination of the liquid medium.

In practice, this manifests itself in the form of two signs - periodic or constant pedal failures, sometimes without returning to the upper position, as well as leaks. Moreover, the leak usually goes through the rod and its seal in the bulkhead of the motor shield directly into the passenger compartment.

There may not be any leakage, since the rod is often well sealed structurally, weakening the cuff due to wear or corrosion of the piston-cylinder pair leads to fluid bypassing along the gap.

As a result, pressure is not created, the powerful clutch spring does not work, and the return force to the GCC is not enough to move the piston back. But even if it moves away, and the pedal rises under the action of its own spring, repeated pressing occurs without the usual effort, and the clutch does not turn off.

Causes of malfunction of the clutch slave cylinder

With the working cylinder, the situation is simple and unambiguous, if it bypasses the piston seal, then the liquid flows out.

This is clearly visible from above by the disappearance of the level in the reservoir and a puddle or abundant oiling from below on the clutch housing. There are no diagnostic problems.

Sometimes the fluid does not go away, but air enters the cylinder through the cuff. Pumping helps only for a while. This does not last long, a leak appears.

Clutch Master Cylinder Repair

Once upon a time, with a shortage of spare parts, it was customary to repair worn cylinders. Repair kits were produced, where the base was a cuff, sometimes a piston and a return spring, as well as less significant parts.

It was assumed that the craftsman (it is unlikely that it will be possible to force a professional service station to do this) will remove and disassemble the GCC, replace the cuff, clean it from corrosion and polish the cylinder mirror. Hoping at the same time that in the repair kit all the parts are made with high quality and will last longer than a couple of weeks.

Watch this video on YouTube

Despite the presence of this even now, there is no point in repairing the GCC. There is an abundance of assembled products from numerous companies on the market, sometimes with a quality that exceeds the original.

Prices are quite reasonable and in a wide range, from "for sale" to "eternal". In practice, we can say that a part from a well-known manufacturer is really very durable, but on one condition - the liquid must be completely changed with flushing at least once every two years.

RCS repair

All of the above can be attributed to the working cylinder. Access to it is simple, it costs even less than the GCC, the choice is huge. Although theoretically it is possible to repair if you can find a repair kit with acceptable quality.

Watch this video on YouTube

And take into account at the same time that the rod, the clutch fork are already worn out, all the threads are thoroughly stuck, and it will not be possible to remove deep corrosion, for this it would be necessary to bore the cylinder and install parts of repair dimensions that are not produced. All this can not be cheaper than a simple replacement assembly.

One comment

anonym

Where is the answer to the question in the title?